中国激光, 2019, 46 (9): 0903001, 网络出版: 2019-09-10

稀土对Ti基激光熔覆层组织与摩擦磨损性能的影响  下载: 1212次

下载: 1212次

Effect of Rare Earth on Microstructure and Friction and Wear Properties of Ti-Based Laser Cladding Layer

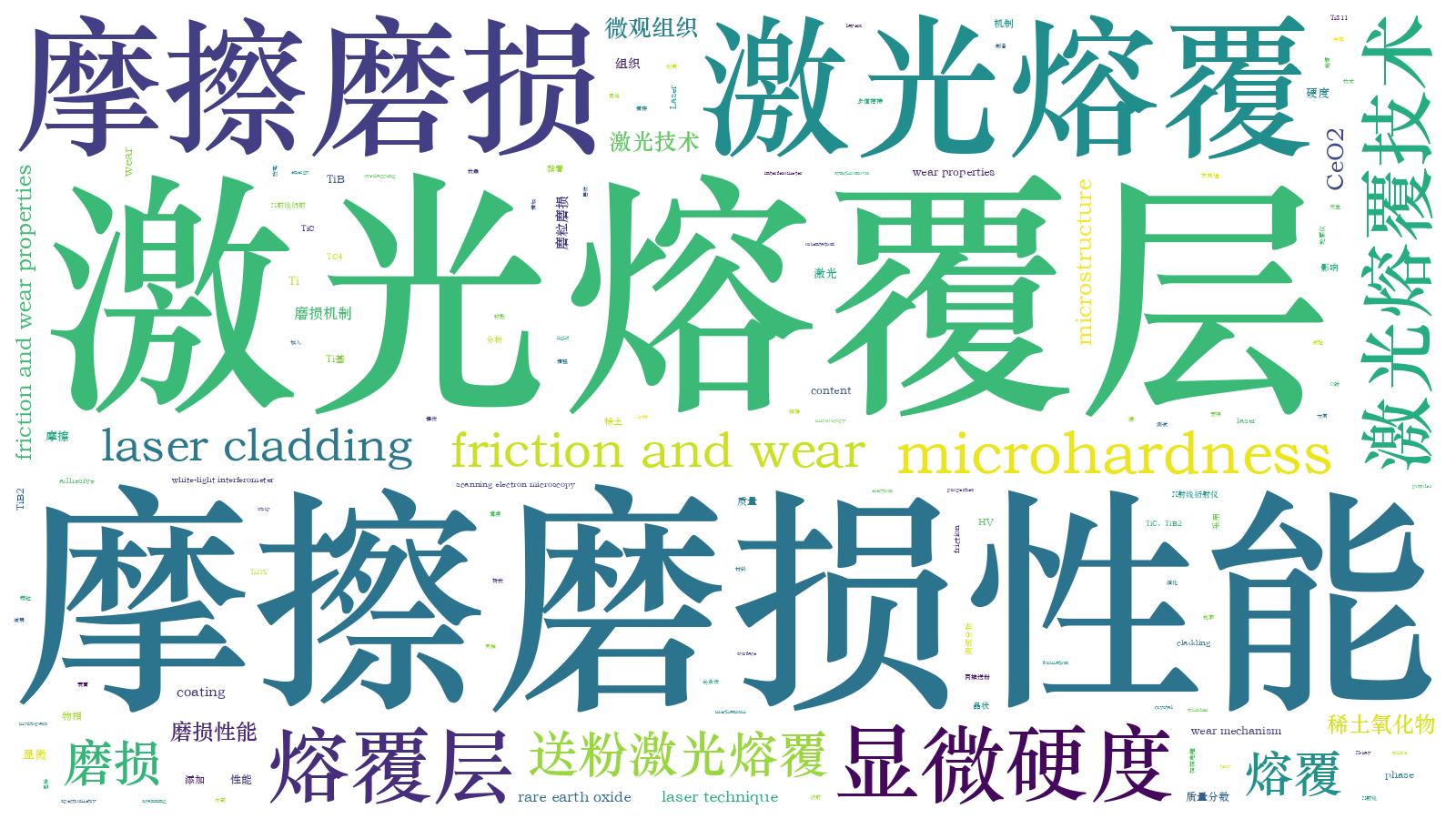

激光技术 激光熔覆 稀土氧化物 微观组织 显微硬度 摩擦磨损 laser technique laser cladding rare earth oxide microstructure microhardness friction and wear

摘要

采用同轴送粉激光熔覆技术在Ti811表面制备了CeO2质量分数分别为0,1%,3%的TC4+Ni45+CeO2多道搭接激光熔覆层。采用X射线衍射仪、扫描电镜和能谱仪分析了熔覆层的微观组织和物相,利用显微硬度计、摩擦磨损试验机和白光轮廓仪测试分析了熔覆层的显微硬度和摩擦磨损性能。结果表明:熔覆层中的物相包括TiC、TiB2、TiB、Ti2Ni和α-Ti;随着CeO2加入量增加,熔覆层中的物相未发生改变;当CeO2添加量为0时,熔覆层内部组织粗大,显微硬度为590~640 HV,磨损机制主要为磨粒磨损和黏着磨损;当添加CeO2的质量分数为1%时,熔覆层组织逐步细化,枝晶的方向性减弱,显微硬度为625~655 HV,磨损机制主要为磨粒磨损和黏着磨损;当添加CeO2的质量分数为3%时,熔覆层中的增强相由树枝晶状、长条状、须晶状向颗粒状、层状、短棒状转变,且均匀弥散地分布于熔覆层中,显微硬度为560~575 HV,磨损机制主要为磨粒磨损。

Abstract

TC4+Ni45+CeO2 multi-pass overlapping laser cladding layers with 0, 1%, and 3% CeO2 content are achieved on the surface of Ti811 using synchronous powder-feeding laser cladding. The microstructure and phase compositions of the coating are analyzed via X-ray diffractometry, scanning electron microscopy, and energy dispersive spectrometry. The microhardness and friction and wear properties of the coating are investigated via a microhardness tester, friction and wear test machine, and white-light interferometer. The results demonstrate that the formation phases in the coating include TiC, TiB2, TiB, Ti2Ni, and α-Ti. With the addition of CeO2, the phase compositions of the coating remain unchanged. When the CeO2 content is 0, the internal crystal grains are coarse, the microhardness is 590-640 HV, and the wear mechanisms are primarily abrasive and adhesive wears. When the CeO2 content is 1%, the microstructure of the coating is refined, the orientation of dendrites is weakened, the microhardness is 625-655 HV, and the wear mechanisms are primarily abrasive and adhesive wears. When the CeO2 content is 3%, the reinforcing phase in the coating is changed from dendritic, long strip, and whisker-like to granular, layered, short rod-like, and is uniformly dispersed in the coating. Under this condition, the microhardness is 560-575 HV, and the wear mechanism is primarily abrasive wear.

张天刚, 庄怀风, 肖海强, 柏明磊, 安通达. 稀土对Ti基激光熔覆层组织与摩擦磨损性能的影响[J]. 中国激光, 2019, 46(9): 0903001. Zhang Tiangang, Zhuang Huaifeng, Xiao Haiqiang, Bai Minglei, An Tongda. Effect of Rare Earth on Microstructure and Friction and Wear Properties of Ti-Based Laser Cladding Layer[J]. Chinese Journal of Lasers, 2019, 46(9): 0903001.