中国激光, 2020, 47 (11): 1100001, 网络出版: 2020-11-02

激光粉末床熔融制备金属骨植入物  下载: 1439次

下载: 1439次

Laser Powder Bed Fusion for Fabrication of Metal Orthopedic Implants

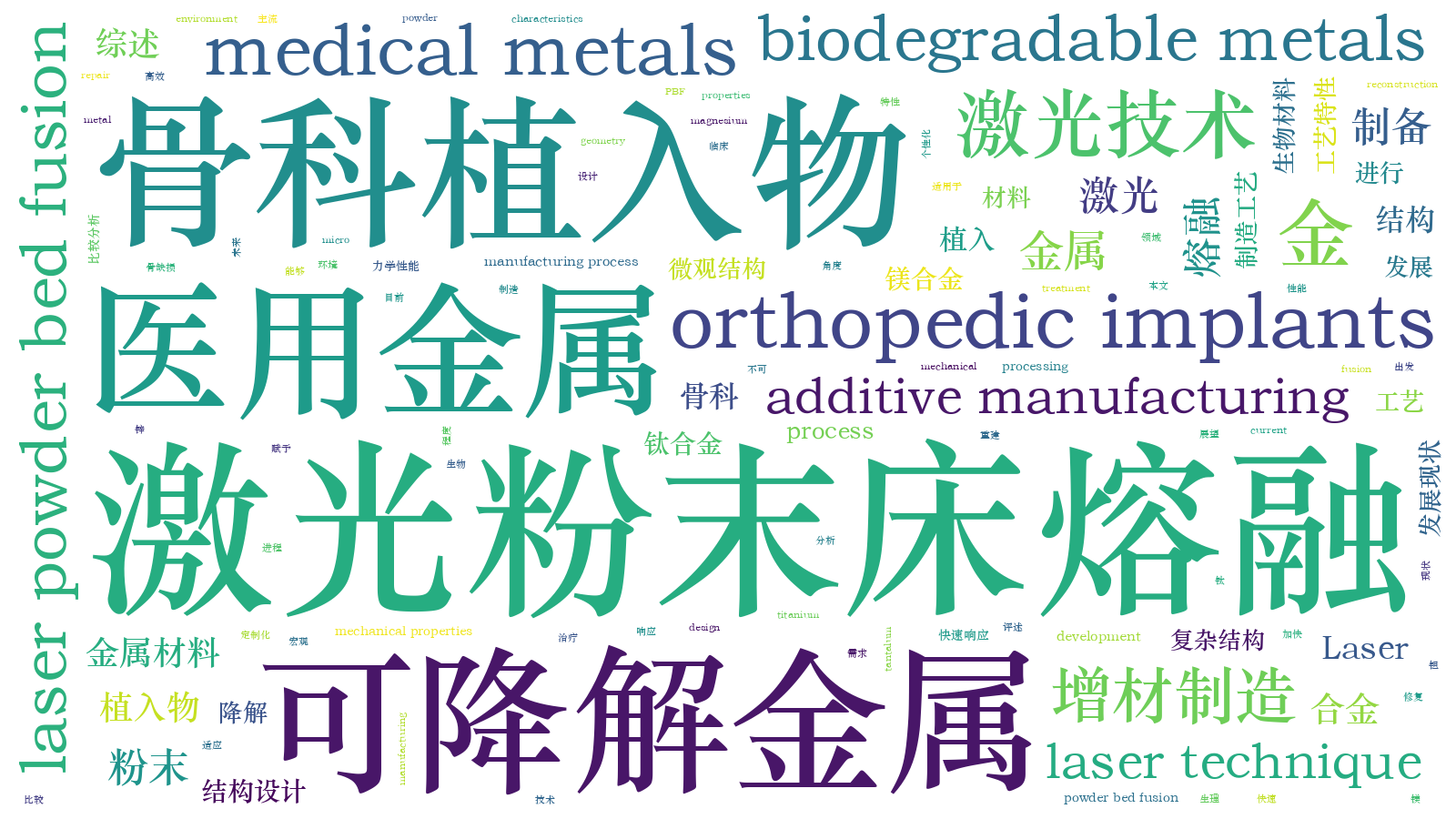

激光技术 激光粉末床熔融 增材制造 医用金属 可降解金属 骨科植入物 laser technique laser powder bed fusion additive manufacturing medical metals biodegradable metals orthopedic implants

摘要

激光粉末床熔融(L-PBF)能够精确高效地制备复杂结构,适用于目前主流的医用金属材料,可赋予骨科植入物定制化的宏观微观结构,快速响应个性化的临床治疗需求,最大程度地适应骨缺损部位的生理环境并加快骨修复重建进程。本文从生物材料、结构设计和制造工艺角度出发,全面评述了激光粉末床熔融制备金属骨科植入物的发展现状,重点对钛合金和钽合金等不可降解金属以及镁合金和锌合金等可降解金属的激光粉末床熔融工艺特性及力学性能进行了比较分析,并对该技术在骨科植入物制备领域的未来发展进行了展望。

Abstract

Laser powder bed fusion (L-PBF) can accurately and efficiently produce complicated structures made of various medical metals, giving orthopedic implants with customized macro and micro geometry, so that they can quickly respond to personalized clinical treatment needs according to the specific physiological environment, and accelerate the process of bone repair and reconstruction to the greatest extent. This article firstly introduces the current development of metal orthopedic implants fabricated by the L-PBF from the perspective of biomaterials, structural design and manufacturing process in general. Then, it discusses the unique processing characteristics and mechanical properties of non-degradable metals such as titanium and tantalum alloys and biodegradable metals such as magnesium and zinc alloys. Finally, the future development of the L-PBF in the field of orthopedic implants preparation is prospected.

尹浜兆, 秦瑜, 温鹏, 郑玉峰, 田耘. 激光粉末床熔融制备金属骨植入物[J]. 中国激光, 2020, 47(11): 1100001. Yin Bangzhao, Qin Yu, Wen Peng, Zheng Yufeng, Tian Yun. Laser Powder Bed Fusion for Fabrication of Metal Orthopedic Implants[J]. Chinese Journal of Lasers, 2020, 47(11): 1100001.