中国激光, 2020, 47 (10): 1002008, 网络出版: 2020-10-09

激光增材制造Ti-6Al-2Mo-2Sn-2Zr-2Cr-2V钛合金组织与疲劳性能研究  下载: 1120次

下载: 1120次

Microstructures and Fatigue Properties of Ti-6Al-2Mo-2Sn-2Zr-2Cr-2V Titanium Alloy Fabricated Using Laser Deposition Manufacturing

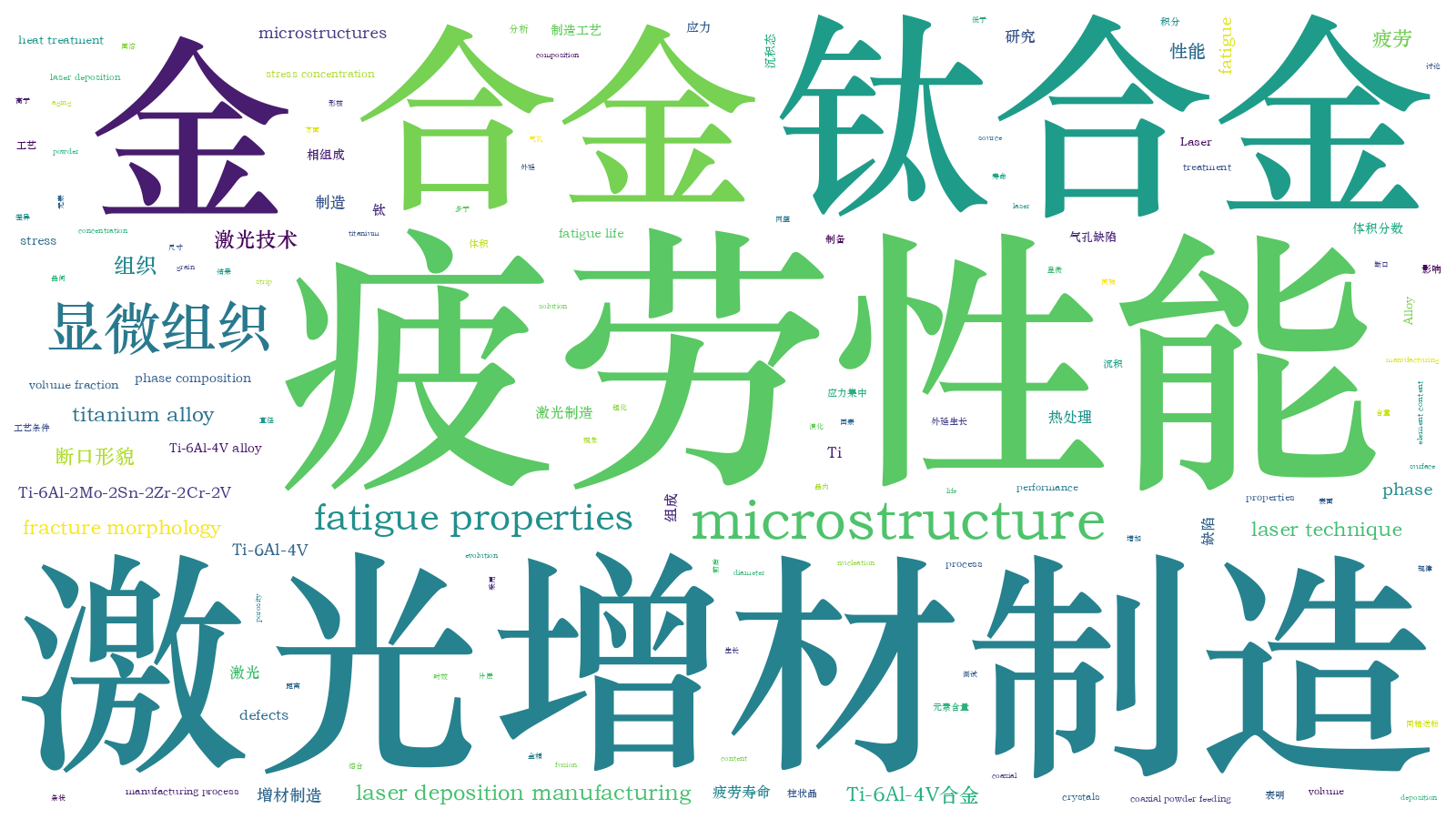

激光技术 激光增材制造 钛合金 显微组织 疲劳性能 断口形貌 laser technique laser deposition manufacturing titanium alloy microstructure fatigue properties fracture morphology

摘要

采用同轴送粉激光增材制造工艺制备了Ti-6Al-2Mo-2Sn-2Zr-2Cr-2V钛合金,研究了沉积态及热处理态合金的组织,测试了热处理后合金的疲劳性能,分析了热处理前后合金组织的演化规律,讨论了显微组织、组织缺陷对疲劳性能的影响。研究结果表明:沉积态合金组织由向外延生长的粗大β柱状晶组成,晶内为细长的α片层和晶间β相组成的网篮组织,α相的体积分数明显多于β相;在两相区固溶时效后,组织仍由粗大的柱状晶组成,晶内α相粗化,β相体积分数明显增加;与同工艺条件下制备的Ti-6Al-4V合金相比,热处理Ti-6Al-2Mo-2Sn-2Zr-2Cr-2V合金的疲劳性能在高应力区高于Ti-6Al-4V合金,在低应力区低于Ti-6Al-4V合金;两合金在合金元素含量、相组成、组织尺寸等方面的差异是影响疲劳性能的主要因素;断口分析表明,疲劳源均形核于条状未熔合缺陷及气孔缺陷处,且缺陷直径越大,距离表面越近,应力集中现象越明显,疲劳寿命越低。

Abstract

Ti-6Al-2Mo-2Sn-2Zr-2Cr-2V titanium alloy is prepared using a coaxial powder feeding laser deposition manufacturing process. The microstructures of the alloy in deposited and heat-treated state are studied, and the fatigue properties of the heat-treated alloy are evaluated after heat treatment. The evolution law of microstructure before and after heat treatment is analyzed, and the effects of microstructure and defects on fatigue properties are discussed. Results show that the microstructure of the deposited alloy is composed of thick primary β-columnar crystals, and the interior of the grain is composed of thin lamella α and intergranular β-phases. The volume fraction of the α-phase is significantly more than that of the β-phase. After solution and aging in the (α+β) phase region, the microstructure is still composed of coarse primary columnar crystals, the intracrystalline α-phase coarsens, and the β-phase volume fraction evidently increases. Compared with Ti-6Al-4V alloy samples prepared with the same process, the fatigue performance of the heat-treated experimental alloys is higher in the high-stress zone but lower in the low-stress zone. The difference in alloy element content, phase composition, and microstructure were the main factors affecting the fatigue performance of the deposited and heat-treated alloys. Fracture analysis shows that most of the nucleation sites of the fatigue source are located at the strip-shaped non-fusion defects and the porosity defects, and the larger the diameter of the defects, the closer to the surface, the more obvious the stress concentration, and the lower the fatigue life.

钦兰云, 吴佳宝, 王伟, 王超, 李长富, 杨光. 激光增材制造Ti-6Al-2Mo-2Sn-2Zr-2Cr-2V钛合金组织与疲劳性能研究[J]. 中国激光, 2020, 47(10): 1002008. Qin Lanyun, Wu Jiabao, Wang Wei, Wang Chao, Li Changfu, Yang Guang. Microstructures and Fatigue Properties of Ti-6Al-2Mo-2Sn-2Zr-2Cr-2V Titanium Alloy Fabricated Using Laser Deposition Manufacturing[J]. Chinese Journal of Lasers, 2020, 47(10): 1002008.