激光与光电子学进展, 2020, 57 (22): 221502, 网络出版: 2020-11-12

基于线阵图像深度学习的电池组焊缝瑕疵检测  下载: 1167次

下载: 1167次

Weld Defect Inspection of Battery Pack Based on Deep Learning of Linear Array Image

机器视觉 焊缝检测 线阵相机 深度学习 图像处理 machine vision weld inspection line-scan camera deep learning image processing

摘要

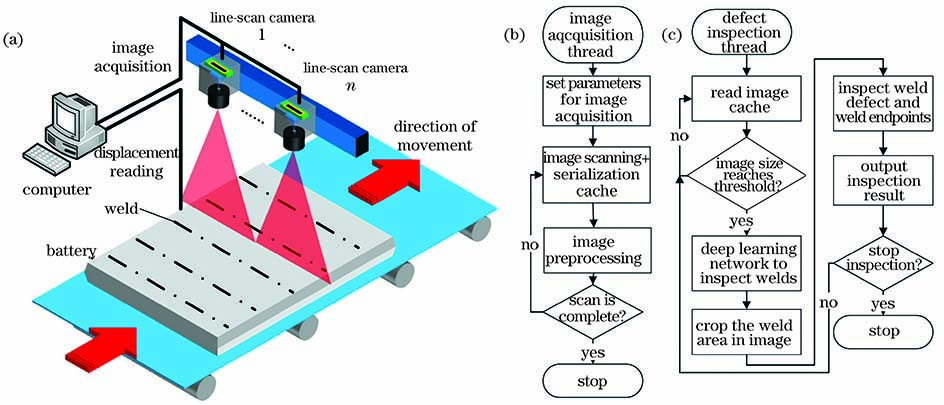

为实现对激光焊缝质量的高效检测,引入了线阵图像传感解决在线检测问题,提出了一种基于深度学习的焊缝瑕疵快速检测方法。首先,针对激光焊缝瑕疵,优化了基于YOLO(You only look once)的深度学习网络。其次,在实验数据集中加入了合适的锚框,以提高检测框定位信息的准确度,并通过多尺度特征融合技术提高了瑕疵的识别准确度。最后,制作数据集并提出了一种数据集预处理方法训练网络,提升了瑕疵的识别效果。实验结果表明,本方法对焊缝单孔、穿孔、凹槽瑕疵的总识别率大于94%,对尺寸为4096pixel×4000pixel的单张工件图像的检测时间为0.97s,相比传统超声、射线图像检测方法在检测速度方面有明显提升。

Abstract

In order to realize efficient inspection of laser welding quality, this paper introduces linear array image sensing to address online inspection, and proposes a fast inspection method of weld defect based on deep learning. First, aiming at the laser weld defect, a deep learning network based on Yolo (You only look once) is optimized. Then, an appropriate anchor frame is added to the experimental data set to improve the accuracy of detection frame positioning information, and multi-scale feature fusion technology is used to improve the accuracy of defect recognition, Finally, the data set is made and a data set preprocessing method is proposed to train the network, which improves the recognition effect of defects. Experimental results show that the total recognition rate of single hole, perforation and groove defect is more than 94%, and the detection time of single workpiece image with size of 4096pixel×4000pixel is 0.97s, which is significantly faster than traditional ultrasonic and radiographic image detection methods.

吴桐, 杨金成, 廖瑞颖, 杨凌辉. 基于线阵图像深度学习的电池组焊缝瑕疵检测[J]. 激光与光电子学进展, 2020, 57(22): 221502. Tong Wu, Jincheng Yang, Ruiying Liao, Linghui Yang. Weld Defect Inspection of Battery Pack Based on Deep Learning of Linear Array Image[J]. Laser & Optoelectronics Progress, 2020, 57(22): 221502.