光电工程, 2023, 50 (3): 220322, 网络出版: 2023-05-04

飞秒激光直写加工SERS基底及其应用  下载: 715次

下载: 715次

Femtosecond laser direct writing processing of SERS substrates and applications

表面增强拉曼光谱 飞秒激光直写 微纳加工 SERS基底 SERS femtosecond laser direct writing micro/nano processing SERS substrate

摘要

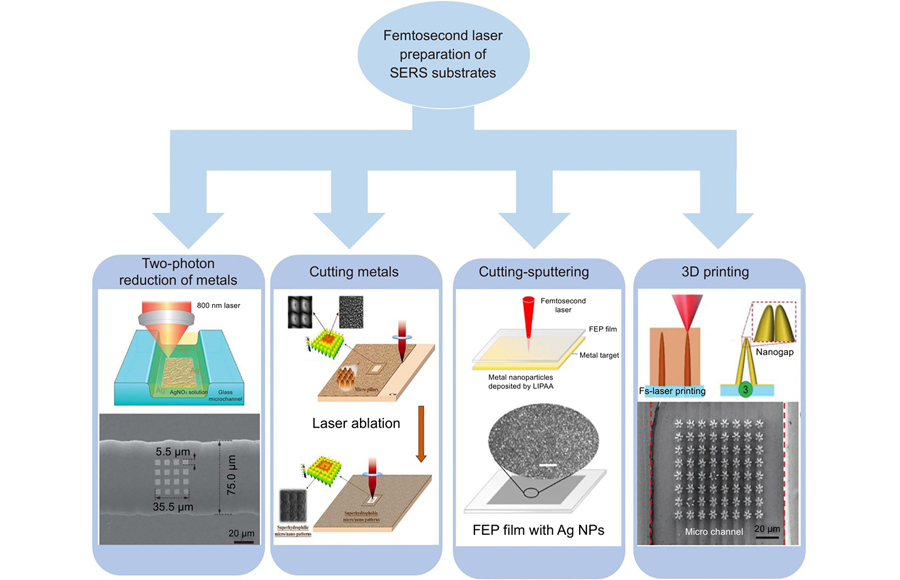

Overview: Surface-Enhanced Raman spectroscopy (SERS) is a highly sensitive and high-resolution molecular recognition technique with important applications in many fields. As an emerging low-cost, high-resolution, and highflexibility micro-nano processing method, femtosecond laser direct writing has been widely used in the field of preparing SERS substrates. Compared with traditional processing methods for preparing SERS substrates, femtosecond laser direct writing processing has certain advantages in terms of flexibility, three-dimensional molding, processing material range, processing accuracy, and other aspects. In this review, we classify the processing methods of femtosecond laser preparation of SERS substrates into four categories, including femtosecond laser two-photon metal reduction, femtosecond laser cutting metal, femtosecond laser cutting-sputtering, and femtosecond laser 3D printing. Femtosecond laser two-photon metal reduction uses the two-photon reduction effect to reduce metal cations in metal solutions to metals, such as silver ions in silver nitrate solutions to silver nanoparticles. This method is suitable for the one-step preparation of SERS substrates in closed microchannels. Femtosecond laser cutting metal directly prepares the SERS substrate structure on a metal substrate. This method takes advantage of the high peak power of the femtosecond laser to ablate the surface of the metal sample to obtain a patterned surface structure. At the same time, femtosecond laser ablation produces particle fragments, which are usually redeposited on the patterned surface, resulting in SERS "hot spots". Femtosecond laser direct cutting of metal can prepare SERS substrates in one step, which has the advantages of high processing efficiency and simple processing and is more conducive to the application of large-scale production of practical SERS detection. Femtosecond laser cutting-sputtering is to process any structure on non-metallic substrates such as polymers and then sputtering/evaporating metal nanoparticles on the surface of the structure. This method can prepare transparent and flexible SERS substrates, which are rich in application scenarios. Femtosecond laser 3D printing is to use the three-dimensional processing ability of femtosecond lasers to obtain rich "hot spots" by designing the structure of SERS substrates, and then using template-guided self-assembly technology with different driving forces to deposit/evaporate metal nanoparticles at designated locations. In this paper, we first introduce the current methods for preparing SERS and then conduct a comprehensive review of the processing methods of four femtosecond lasers to prepare SERS substrates. Finally, the advantages and disadvantages of the four femtosecond laser preparation methods for SERS substrate are briefly summarized, and the development prospects of this technology are prospected, aiming to provide it for future related research.

Abstract

Surface-enhanced Raman spectroscopy (SERS) technique plays an important role in molecular recognition fields due to its highly sensitive and high-resolution. As an emerging low-cost, high machining accuracy, and high-flexibility processing method, femtosecond laser direct writing processing has been widely used in the field of preparing SERS substrates. This work introduces four methods of preparing SERS substrates by femtosecond laser direct writing, including femtosecond two-photon reduction, femtosecond laser cutting metal, femtosecond laser cutting-sputtering, and femtosecond laser 3D printing. The article introduces the performance and application scenarios of each method in preparing SERS substrates and illustrates the advantages of femtosecond laser direct writing processing in preparing SERS substrates, aiming to provide a reference for future related research.

尹智东, 倪才鼎, 吴思竹, 劳召欣. 飞秒激光直写加工SERS基底及其应用[J]. 光电工程, 2023, 50(3): 220322. Zhidong Yin, Caiding Ni, Sizhu Wu, Zhaoxin Lao. Femtosecond laser direct writing processing of SERS substrates and applications[J]. Opto-Electronic Engineering, 2023, 50(3): 220322.