光电工程, 2023, 50 (3): 220048, 网络出版: 2023-05-04

飞秒激光双光子聚合三维微纳结构加工技术  下载: 672次

下载: 672次

Femtosecond laser two-photon polymerization three-dimensional micro-nanofabrication technology

飞秒激光 双光子聚合 光学衍射极限 加工分辨力 加工效率 femtosecond laser two-photon polymerization optical diffraction limit resolution efficiency

摘要

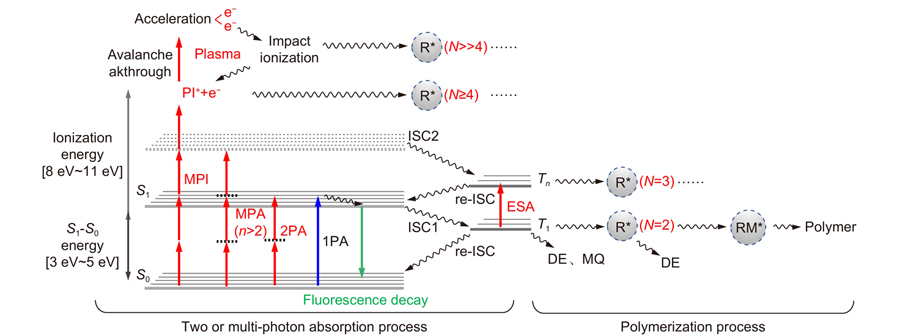

Overview: Femtosecond laser two-photon polymerization (TPP) micro-nanofabrication technology is a new type of three-dimensional lithography technology that integrates nonlinear optics, ultra-fast pulsed laser, microscopic imaging, ultra-high-precision positioning, three-dimensional (3D) graphics CAD modeling, and photochemical materials. It has the characteristics of simplicity, low cost, high resolution, true 3D, and so on. Different from the technical route of shortening the wavelength of the traditional lithography, this TPP technology breaks through the optical diffraction limit using the ultrafast laser in the near-infrared and the nonlinear optical effect of the interaction between the laser and the material. TPP can achieve true 3D fabrication of complex 3D structures. After the femtosecond pulse laser is tightly focused in space, photopolymerization is initiated by the two-photon absorption(TPA), which can limit the fabrication area in the center of the focus. The interaction time of the ultrashort pulse with the material is much lower than the thermal relaxation of the material, avoiding the photothermal effect. The lateral linewidth can be reduced to about 100 nm due to the strong threshold characteristics of the two-photon absorption process. Thus, TPP is an ideal fabrication method in the field of 3D micro-nanostructure. Since 2001, Kawata’s team has used a near-infrared femtosecond laser with a wavelength of 780 nm to fabricate a "nanobull" with the size of red blood cells. It fully demonstrated the advantages of TPP in the preparation of three-dimensional micro-nano structures. At the same time, a polymer nanodot with a size of 120 nm was fabricated, which was only 1/7 of the laser wavelength, breaking the optical diffraction limit in this study. Since then, scientists from various countries have improved the line width, resolution, and other parameters of 3D structure by continuously improving the materials, structure, processing technology and light field control, and other aspects. At the same time, with the continuous development and improvement of the 3D nanostructure fabrication technology, the advantages of TPP technology are also reflected in some application fields, such as micro-optical devices, integrated optical devices, micro-electromechanical systems, and biomedical devices. This paper will systematically introduce the femtosecond laser TPP micro-nanofabrication technology, including the fabricating principle, the development of fabricating methods, and its research overview in many application fields. Finally, its existing problems and future development and application prospects are discussed.

Abstract

Femtosecond laser two-photon polymerization (TPP) micro-nano fabrication technology, as an important method for the preparation of three-dimensional (3D) micro-nanostructures, has become a hot spot of international frontier research. Using the two-photon absorption effect and the threshold effect of the interaction between laser and matter, this technology can break through the diffraction limit of classical optical theory and achieve nanoscale laser fabrication resolution. It is expected to play an important role in the field of 3D functional micro-nano device fabrication. In this paper, the basic principles of photophysical and photochemical processes in femtosecond pulsed laser TPP fabrication technology will be described, and the research progress and development of this technology in improving line width and fabrication resolution, and improving fabrication efficiency will be reviewed. Then, using the high spatial resolution and true 3D fabrication characteristics of femtosecond laser TPP micro-nano fabrication technology, the researchers prepared various micro-optical devices, integrated optical devices, micro-electromechanical systems, and biomedical devices, fully demonstrating the application prospect of this technology. Finally, how to achieve high-precision, high-efficiency, low-cost, large-area, multi-functional materials and microstructure fabrication, as well as existing challenges and future development directions are discussed and prospected.

赵圆圆, 金峰, 董贤子, 郑美玲, 段宣明. 飞秒激光双光子聚合三维微纳结构加工技术[J]. 光电工程, 2023, 50(3): 220048. Yuanyuan Zhao, Feng Jin, Xianzi Dong, Meiling Zheng, Xuanming Duan. Femtosecond laser two-photon polymerization three-dimensional micro-nanofabrication technology[J]. Opto-Electronic Engineering, 2023, 50(3): 220048.