1 广东正业科技股份有限公司,广东 东莞 523000

2 吉林大学电子科学与工程学院,吉林 长春 130012

针对硬质材料高数值孔径()微透镜阵列制备难的问题,提出一种基于像差的自调制激光加工方法。该方法将飞秒激光聚焦于石英衬底的下表面,能够实现对激光焦点的纵向拉伸,结合氢氟酸溶液湿法刻蚀实现了具有高数值孔径微透镜的制备。结果表明,利用该技术通过改变单脉冲能量能够对微透镜形貌进行调控,在此基础上进一步优化离焦位置,有效地增大了微透镜的数值孔径,制备出达到理论极限(=0.46)的高数值孔径石英微透镜。相对于传统的正面加工方法,所提方法方式不仅提升了微透镜的数值孔径,而且无需复杂的光调制系统,对于高性能硬质材料微透镜阵列的制备与实际应用具有重要的意义。

激光技术 飞秒激光加工 高数值孔径 微透镜阵列 熔融石英 光学学报

2023, 43(16): 1623019

吉林大学电子科学与工程学院,集成光电子学国家重点实验室,吉林 长春 130012

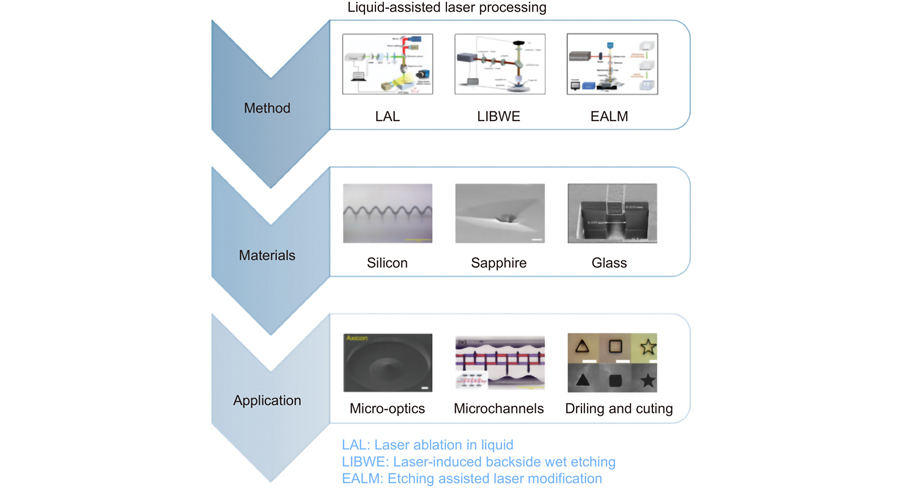

Overview: With the development of industry, laser fabrication has become one of the important technologies for welding, cutting, surface processing, and other advanced manufacturing areas. At the same time, the pursuit of structures miniaturization, devices integration, and high precision has put forward more stringent requirements for laser fabrication technologies. Due to the advantages of stable mechanical and chemical properties and unique photoelectric properties, hard and brittle materials have been widely used in aerospace, the photoelectric industry, et al. Laser fabrication is an ideal technology for hard and brittle materials processing due to its high precision, high energy, and non-contact properties. In order to achieve the removal of hard and brittle materials, high laser energy is usually required, resulting in low fabrication accuracy and poor surface quality. As an improved laser processing method, liquidassisted laser fabrication can effectively improve fabrication accuracy and surface quality. The processing characteristics and material removal principles of three different liquid-assisted laser processing technologies are summarized in this review. According to the different functions of the medium through which the laser penetrates and the kinds of liquid, liquid-assisted laser fabrication technology can be divided into Laser ablation in liquid (LAL), laser-induced backside wet etching (LIBWE), and etching-assisted laser modification (EALM). The auxiliary liquid of Laser ablation in liquid is mostly water, which mainly plays the role of cooling and removing debris. The auxiliary liquids used by laser-induced backside wet etching include organic solvents, acid-base solutions, inorganic salts, and other liquids, which play different roles according to different liquids. The etching-assisted laser modification mainly uses an acid or alkaline solution as an auxiliary liquid to remove laser-modified materials. Different methods and auxiliary liquids have different mechanisms in the methods. Therefore, almost any material can be processed by choosing suitable methods and auxiliary liquids, including photosensitive glass, silicon crystal, sapphire, and other transparent hard brittle materials. Here, we summarize the fabrication technologies and fabrication parameters for different materials. The development and applications of liquid-assisted laser fabrication technologies in the fields of micro-optical components, microfluidic devices, and drilling and cutting are introduced. Finally, the challenges of the technology are discussed.

激光加工 硬脆材料 液体辅助制造 微/纳米结构 laser fabrication hard and brittle materials liquid assisted fabrication micro/nano structures