1 中国科学院理化技术研究所有机纳米光子学实验室,北京 100190

2 中国科学院大学,北京 100049

三维(3D)无机微纳结构在光子学、量子信息、航空航天、能源等领域发挥着重要作用。利用传统制备方法获得的无机微结构通常分辨率较低和形貌不可控。因此,3D无机微纳结构的精确可控制备成为亟待解决的难题。激光加工具有高精度、形貌可控等优势,能够实现真3D、高分辨、多尺度复杂3D微纳结构的制备,解决3D无机微纳结构的精确可控制备难题。本文综述了激光加工制备无机微纳结构的研究进展,首先讨论了连续激光和超快脉冲激光加工方式,重点针对飞秒激光加工技术,阐述了基于纯无机材料体系、有机-无机杂化体系,以及聚合物模板法等制备3D无机微纳结构的方法。随后,总结了近年来激光加工3D无机微纳结构在光学器件、量子芯片、信息存储与防伪、航空航天以及仿生结构等领域的应用。最后,展望了激光加工3D无机微纳结构的未来发展趋势。

三维无机微纳结构 激光加工 飞秒激光 光与物质相互作用 微型器件 激光与光电子学进展

2024, 61(19): 1900001

1 流体动力基础件与机电系统全国重点实验室,浙江大学机械工程学院,浙江 杭州 310027

2 极端光学技术与仪器全国重点实验室,浙江大学光电科学与工程学院,浙江 杭州 310027

3 萨本栋微米纳米科学技术研究院,厦门大学机电工程系,福建 厦门 361102

柔性微纳传感器的新兴发展对先进制造技术提出了更高要求。其中,激光融合制造充分集成激光增材、等材、减材加工形式,凭借高精度、非接触、机理丰富、灵活可控、高效环保、多材料兼容等特点突破了传统制造在多任务、多线程、多功能复合加工中的局限,通过激光与物质相互作用实现跨尺度“控形”与“控性”,为各类柔性微纳传感器的结构-材料-功能一体化制造开辟了新途径。本文首先分析激光增材、等材与减材制造的技术特点与典型目标材料,展示激光融合制造的技术优势,接着针对近年来激光融合制造在柔性物理、化学、电生理与多模态微纳传感器中的典型应用展开讨论,最后对该技术面临的挑战以及未来发展趋势进行了总结与展望,通过多学科交叉互融,开辟柔性微纳传感器制造新路径,拓展激光制造技术的应用场景。

激光融合制造 激光-物质相互作用 微纳制造 柔性电子 柔性微纳传感器

陕西科技大学机电工程学院, 陕西 西安 710021

表面张力自组装技术的一个重要前提就是利用润湿性分区结构将液滴限制在目标区域。提出一种采用微秒脉冲激光在复合基底表面上制造润湿性分区结构的方法。该方法可通过改变激光加工参数控制复合基底表面超疏水涂层的去除面积占比, 进而调控加工区域的润湿性。建立去除面积占比的数学模型和仿真模型, 研究加工参数对去除面积占比以及润湿性的影响。结果表明, 加工区域的去除面积占比与加工速度和扫描线间距成反比。采用不同的加工参数制备了不同的润湿性分区结构并测量了其接触角。试验结果表明, 随着加工速度从100 mm/s提高到9 000 mm/s, 扫描线间距从20 μm增加到150 μm, 加工区域的去除面积占比减小, 接触角从5°以下逐步增大到127°; 随着基底表面与激光焦平面之间距离的绝对值从0增加至3 mm, 加工区域的接触角从5°以下增大到170°以上。进行了微芯片自组装试验, 结果表明, 利用该方法制备的润湿性分区结构可实现液滴限制和微芯片自组装。研究结果为制造润湿性可控的自组装基底提供了新思路。

激光加工 复合基底 润湿性调控 自组装 laser fabrication composite substrates wettability control self-assembly

1 深圳技术大学中德智能制造学院,广东 深圳 518118

2 温州大学机电工程学院,浙江 温州 325200

3 浙江大学机械工程学院,流体动力与机电系统国家重点实验室,浙江 杭州 310027

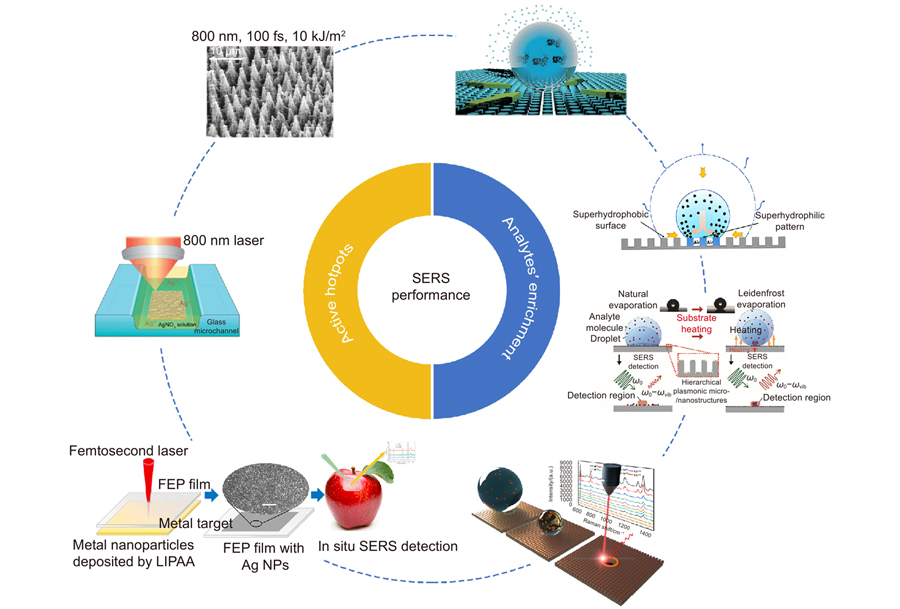

Overview: Surface-enhanced Raman scattering (SERS) affords a rapid, highly sensitive, and nondestructive approach for label-free and fingerprint diagnosis of a wide range of chemicals. This technique has been applied in explosives detection, pre-cancer diagnosis, food safety, and forensic analysis, where a small number of hazardous substances can seriously affect health of human beings. Thus, it is of great significance to prepare high-performance SERS sensors. In general, the signal intensity of SERS is determined by the following three factors: 1) The enhancement effect of surface nanostructure on local electric fields; 2) The number of molecules to be detected in hot spots; 3) Performance of the Raman spectrometer. Therefore, in order to achieve high-performance SERS detection of trace molecules, current research focuses on how to increase the density of hot spots and the number of analyte molecules in the detection area. An ultrafast laser has an ultra-short pulse width and ultra-high peak power, so it can interact with the majority of materials with high processing accuracy and excellent controllability. Meanwhile, it can rapidly construct a variety of large-area micro/nano-structures on material surfaces based on facile digital programming strategies. In addition, combined with multi-beam parallel fast scanning technology, low-cost and high-efficiency machining can be realized without a special requirement for the machining environment. Based on the above advantages, the ultrafast laser has become one of the important means for the fabrication of micro/nano-structures. This is important for the commercial preparation of high-performance SERS sensors. In this paper, we focus on two aspects to introduce the ultrafast laser preparation of high-performance SERS sensors, including how to increase the density of hot spots and the number of analyte molecules in the detection region. Ultrafast lasers can prepare micro/nano-structures with local field enhancement effects by both "bottom-up" and "top-down" processing strategies. The first is based on the "bottom-up" principle, where the reduction, deposition or polymerization of atoms, molecules or other nanoparticles is controlled by ultrafast lasers to achieve additive manufacturing of micro/nano-structures. The other is based on the "top-down" principle, where materials are removed by the ultrafast laser ablation to rapidly achieve hierarchical micro/nanostructures. These structures provide abundant active hot spots for SERS detection. In particular, the superhydrophobic surfaces prepared by the ultrafast laser are one of the most effective methods to achieve the enrichment of analyte molecules. Raman scattering can be excited more effectively by enriched molecules, which is conducive to obtaining higher detection limits and realizing ultra-trace detection. Finally, a prospect for the development of laser-prepared SERS substrates is provided.

超快激光加工 拉曼光谱 表面增强拉曼散射 微纳结构 ultrafast laser fabrication Raman spectroscopy surface-enhanced Raman scattering micro/nano-structures

吉林大学电子科学与工程学院,集成光电子学国家重点实验室,吉林 长春 130012

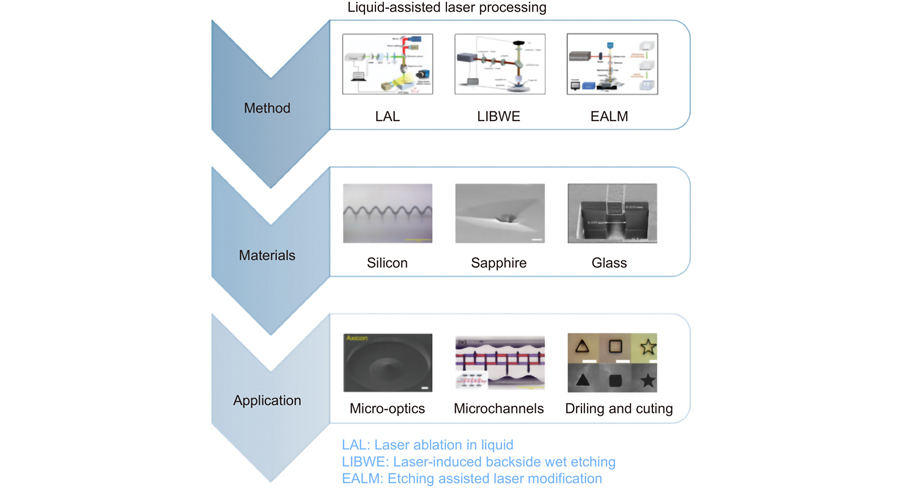

Overview: With the development of industry, laser fabrication has become one of the important technologies for welding, cutting, surface processing, and other advanced manufacturing areas. At the same time, the pursuit of structures miniaturization, devices integration, and high precision has put forward more stringent requirements for laser fabrication technologies. Due to the advantages of stable mechanical and chemical properties and unique photoelectric properties, hard and brittle materials have been widely used in aerospace, the photoelectric industry, et al. Laser fabrication is an ideal technology for hard and brittle materials processing due to its high precision, high energy, and non-contact properties. In order to achieve the removal of hard and brittle materials, high laser energy is usually required, resulting in low fabrication accuracy and poor surface quality. As an improved laser processing method, liquidassisted laser fabrication can effectively improve fabrication accuracy and surface quality. The processing characteristics and material removal principles of three different liquid-assisted laser processing technologies are summarized in this review. According to the different functions of the medium through which the laser penetrates and the kinds of liquid, liquid-assisted laser fabrication technology can be divided into Laser ablation in liquid (LAL), laser-induced backside wet etching (LIBWE), and etching-assisted laser modification (EALM). The auxiliary liquid of Laser ablation in liquid is mostly water, which mainly plays the role of cooling and removing debris. The auxiliary liquids used by laser-induced backside wet etching include organic solvents, acid-base solutions, inorganic salts, and other liquids, which play different roles according to different liquids. The etching-assisted laser modification mainly uses an acid or alkaline solution as an auxiliary liquid to remove laser-modified materials. Different methods and auxiliary liquids have different mechanisms in the methods. Therefore, almost any material can be processed by choosing suitable methods and auxiliary liquids, including photosensitive glass, silicon crystal, sapphire, and other transparent hard brittle materials. Here, we summarize the fabrication technologies and fabrication parameters for different materials. The development and applications of liquid-assisted laser fabrication technologies in the fields of micro-optical components, microfluidic devices, and drilling and cutting are introduced. Finally, the challenges of the technology are discussed.

激光加工 硬脆材料 液体辅助制造 微/纳米结构 laser fabrication hard and brittle materials liquid assisted fabrication micro/nano structures

Author Affiliations

Abstract

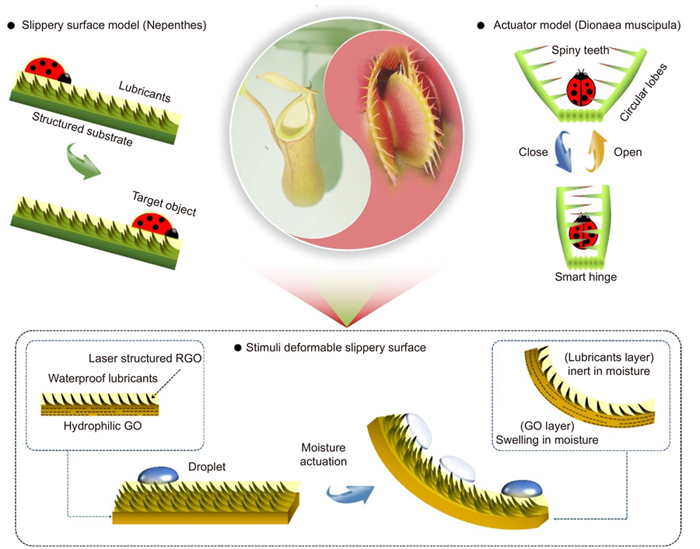

Carnivorous plants, for instance, Dionaea muscipula and Nepenthes pitcher plant, inspired the innovation of advanced stimuli-responsive actuators and lubricant-infused slippery surfaces, respectively. However, hybrid bionic devices that combine the active and passive prey trapping capabilities of the two kinds of carnivorous plants remain a challenge. Herein, we report a moisture responsive shape-morphing slippery surface that enables both moisture responsive shape-morphing and oil-lubricated water repellency for simultaneous active- and passive-droplet manipulation. The moisture deformable slippery surface is prepared by creating biomimetic microstructures on graphene oxide (GO) membrane via femtosecond laser direct writing and subsequent lubricating with a thin layer of oil on the laser structured reduced GO (LRGO) surface. The integration of a lubricant-infused slippery surface with an LRGO/GO bilayer actuator endows the actuator with droplet sliding ability and promotes the moisture deformation performance due to oil-enhanced water repellency of the inert layer (LRGO). Based on the shape-morphing slippery surface, we prepared a series of proof-of-concept actuators, including a moisture-response Dionaea muscipula actuator, a smart frog tongue, and a smart flower, demonstrating their versatility for active/passive trapping, droplet manipulation, and sensing.Carnivorous plants, for instance, Dionaea muscipula and Nepenthes pitcher plant, inspired the innovation of advanced stimuli-responsive actuators and lubricant-infused slippery surfaces, respectively. However, hybrid bionic devices that combine the active and passive prey trapping capabilities of the two kinds of carnivorous plants remain a challenge. Herein, we report a moisture responsive shape-morphing slippery surface that enables both moisture responsive shape-morphing and oil-lubricated water repellency for simultaneous active- and passive-droplet manipulation. The moisture deformable slippery surface is prepared by creating biomimetic microstructures on graphene oxide (GO) membrane via femtosecond laser direct writing and subsequent lubricating with a thin layer of oil on the laser structured reduced GO (LRGO) surface. The integration of a lubricant-infused slippery surface with an LRGO/GO bilayer actuator endows the actuator with droplet sliding ability and promotes the moisture deformation performance due to oil-enhanced water repellency of the inert layer (LRGO). Based on the shape-morphing slippery surface, we prepared a series of proof-of-concept actuators, including a moisture-response Dionaea muscipula actuator, a smart frog tongue, and a smart flower, demonstrating their versatility for active/passive trapping, droplet manipulation, and sensing.

femtosecond laser fabrication graphene oxide moisture responsive actuators slippery surface bionic devices Opto-Electronic Advances

2023, 6(1): 210163

1 吉林大学电子科学与工程学院, 集成光电子学国家重点实验室, 吉林 长春 130012

2 中国空气动力研究与发展中心, 结冰与防除冰重点实验室, 四川 绵阳 621000

受到自然界的猪笼草启发,超滑表面受到了许多关注。本文通过激光加工技术在石墨烯和聚偏氟乙烯的复合材料表面(G@PVDF)进行烧蚀,采用热旋涂法将石蜡材料均匀地填充于网格状沟槽内部。利用共聚焦显微镜(CLSM)和扫描电子显微镜(SEM)表征激光加工后沟槽的形貌与深度,利用UV3600以及红外热成像仪测试样品的光吸收以及光热特性。当复合材料表面未受到强光照射时,液滴“钉”在表面;由于石墨烯具有优异的光热转换能力,当复合材料表面受到强光照射时,复合材料表面吸收光能并产生热量使石蜡融化,液滴与表面由粗糙的气/液/固状态转变为光滑的气/液/润滑剂/固状态,液滴可在倾斜角约10°的状态滑动且无残留。另一方面,通过外界电压也能同样控制液滴的行为。研究结果对于智能化操控液滴有着重要的意义。

中国科学技术大学 精密机械与精密仪器系,安徽合肥230027

为了实现微机器人的快速批量制造,提出一种飞秒贝塞尔光束叠加干涉方法生成带侧瓣的环形光场,并结合动态全息加工术实现了中空螺旋微机器人的高效制造。对根据贝塞尔传输函数生成的贝塞尔全息图进行叠加,并对产生的光场进行仿真和实验测量。利用叠加的全息图加工得到具有不同侧瓣数目(2~4)的环形结构,分析了两种不同参数对侧瓣宽度和圆环直径的影响。通过引入动态全息加工方法,实现了中空双螺旋微机器人的高效快速加工,微机器人宽为25 µm、长度为100 µm。最后,利用旋转磁场驱动微机器人在微流体环境实现运动。实验表明,加工单个微机器人仅需6 s,旋转磁场下微机器人在7 s内沿直线前进400 µm。该动态全息方法能够快速制备出中空双螺旋微机器人并实现无线磁驱动,为批量制造具有运载能力的磁驱微机器人提供了一种新的途径。

激光加工 飞秒激光 贝塞尔光束叠加干涉 动态全息加工 中空双螺旋微机器人 laser fabrication femtosecond laser Bessel beam superposition interference dynamic holographic processing hollow double helix microrobot