中国激光, 2019, 46 (4): 0402011, 网络出版: 2019-05-09

低热输入脉冲激光修复高温合金液化裂纹研究  下载: 888次

下载: 888次

Liquation Cracks in Superalloys Repaired by Low-Heat Input Pulsed Laser

激光技术 激光修复 K452高温合金 液化裂纹 裂纹控制 力学性能 laser technique laser repairing K452 superalloy liquation crack crack control mechanical properties

摘要

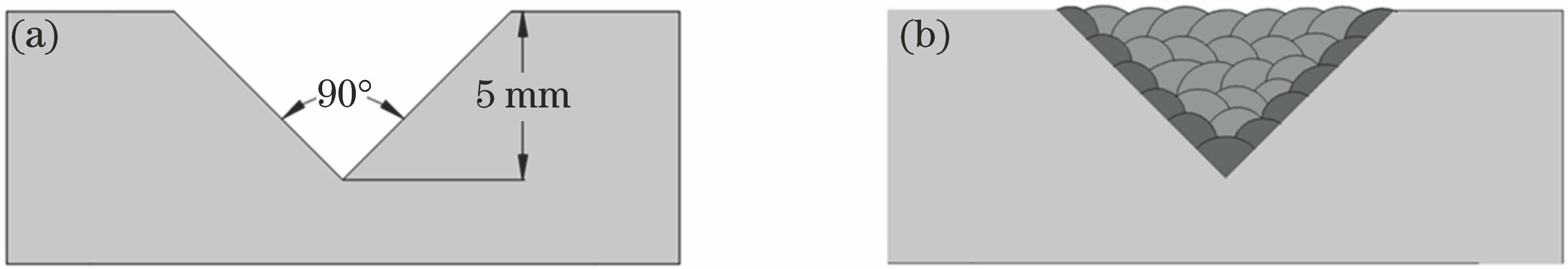

研究了K452高温合金激光增材修复时的开裂特性及液化裂纹产生机理,采用低热输入脉冲激光工艺控制液化裂纹的产生,研究了修复区域的显微组织和力学性能。结果表明,K452高温合金在激光增材修复过程中容易产生液化裂纹,裂纹通常起源于热影响区且沿晶界向基体和修复区域扩展;拉应力作用下热影响区晶界上的液膜形成了液化裂纹。低热输入脉冲激光工艺可以有效控制液化裂纹的产生,脉冲激光修复试样修复区的平均硬度为267.9 HV;抗拉强度和屈服强度分别为814.3 MPa和685.8 MPa,略大于铸态基体的强度;延伸率为4.87%,略小于铸态基体的6.25%。低热输入脉冲激光工艺实现了无裂纹的开槽修复,铸态修复试样强度达到了铸态基体的强度标准,延伸率略低于铸态基体。

Abstract

The cracking characteristics and the liquation cracking mechanism of laser additive repaired K452 superalloys are explored. The low-heat input pulsed laser process is used to control the generation of liquation cracks, and the microstructures and the mechanical properties of the repaired zones are analyzed. The results show that liquation cracks tend to be generated during laser additive repairing of K452 superalloys, which originate from the heat affected zone and extend to the repaired zone and the substrate along the grain boundaries. Under the action of tensile stress, the liquid films on the grain boundaries of the heat-affected zone become liquation cracks. The low-heat input pulsed laser process can effectively control the generation of liquation cracks. The average microhardness of the repaired zone of the pulsed laser repaired sample is 267.9 HV. The tensile strength and the yield strength are 814.3 MPa and 685.8 MPa, respectively, slightly larger than those of the as-cast substrate. The elongation is 4.87%, slightly smaller than 6.25% of the as-cast substrate. The low-heat input pulse laser process achieves crack-free slotting repair. The strength of the as-cast repair specimen reaches the strength standard of the as-cast substrate, and the elongation is slightly lower than that of the as-cast substrate.

赖境, 路媛媛, 张航, 陈浩, 林守钢, 刘德健. 低热输入脉冲激光修复高温合金液化裂纹研究[J]. 中国激光, 2019, 46(4): 0402011. Jing Lai, Yuanyuan Lu, Hang Zhang, Hao Chen, Shougang Lin, Dejian Liu. Liquation Cracks in Superalloys Repaired by Low-Heat Input Pulsed Laser[J]. Chinese Journal of Lasers, 2019, 46(4): 0402011.