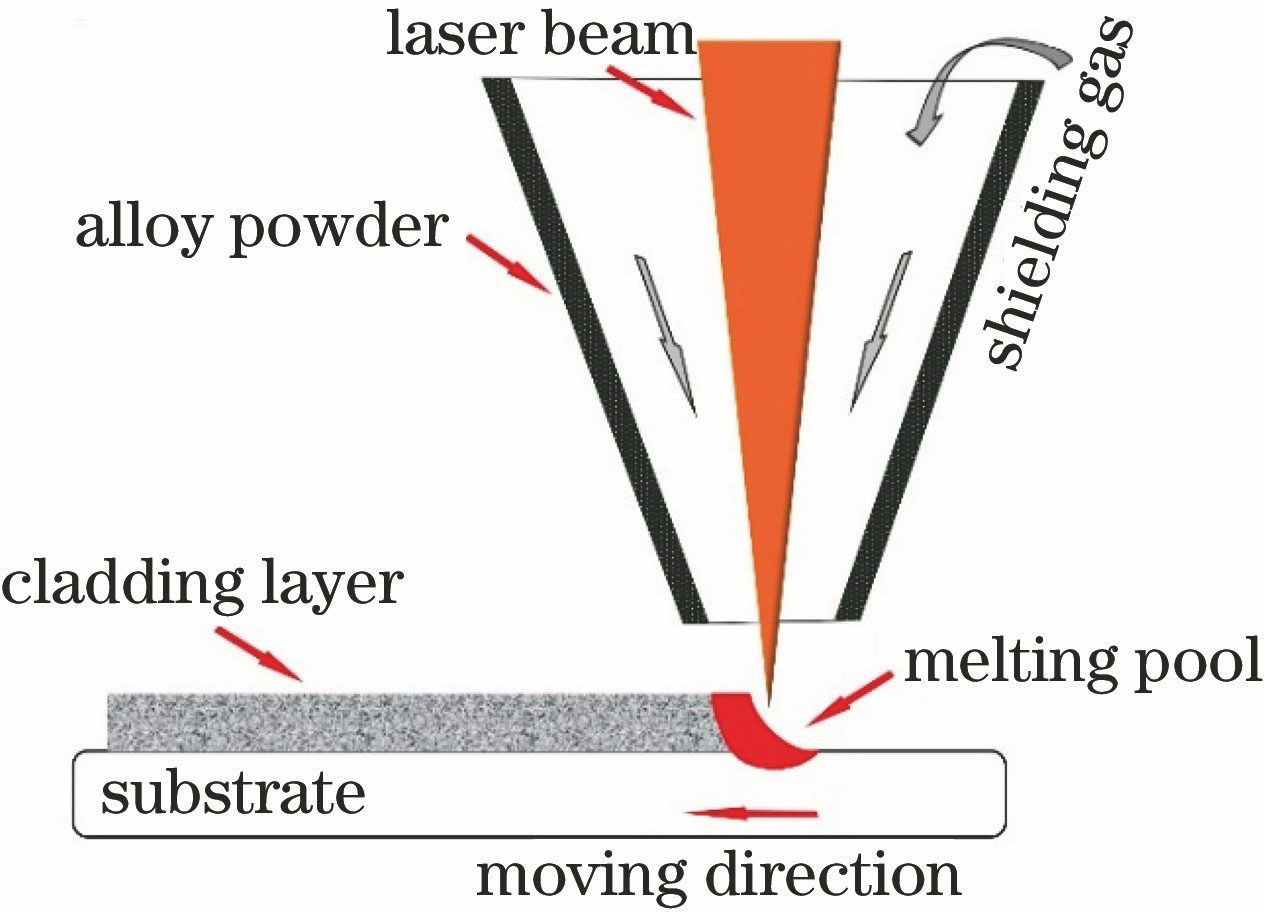

送粉式激光增材制造TC4钛合金熔覆层组织及电化学腐蚀行为的研究  下载: 1301次

下载: 1301次

冯晓甜, 顾宏, 周圣丰, 雷剑波. 送粉式激光增材制造TC4钛合金熔覆层组织及电化学腐蚀行为的研究[J]. 中国激光, 2019, 46(3): 0302003.

Xiaotian Feng, Hong Gu, Shengfeng Zhou, Jianbo Lei. Microstructure and Electrochemical Corrosion Behavior of TC4 Titanium Alloy Cladding Layer Prepared with Powder Feeding Laser Additive Manufacturing[J]. Chinese Journal of Lasers, 2019, 46(3): 0302003.

[1] 原国森, 兖利鹏, 韩艳艳. 钛合金的应用进展[J]. 热加工工艺, 2017, 46(4): 13-16.

[2] Cao S, Zhu S M. Lim C V S, et al. The mechanism of aqueous stress-corrosion cracking of α+β titanium alloys[J]. Corrosion Science, 2017, 125: 29-39.

[4] 王科. 钛合金制备方法的研究进展[J]. 材料导报, 2014, 28(S2): 143-146,158.

Wang K. Progress in manufacture of titaniumalloy[J]. Materials Review, 2014, 28(S2): 143-146,158.

[5] 王舒, 程序, 田象军, 等. TiC添加量对激光增材制造MC碳化物增强Inconel625复合材料组织及性能的影响[J]. 中国激光, 2018, 45(6): 0602002.

[6] 王志会, 王华明, 刘栋. 激光增材制造AF1410超高强度钢组织与力学性能研究[J]. 中国激光, 2016, 43(4): 0403001.

[9] Gasser A, Backes G, Kelbassa I, et al. Laser additive manufacturing[J]. Laser Technik Journal, 2010, 7(2): 58-63.

[12] 刘金, 王薇茜, 程序, 等. 激光增材制造Ti60A钛合金的氧化行为[J]. 中国激光, 2018, 45(7): 0702007.

[13] Wang P, Huang Z H, Qi W J, et al. Application and research progress on titanium alloy printed by 3D technology[J]. Material Sciences, 2017, 7(3): 275-282.

[17] PolmearI, StjohnD, Nie JF, et al. Titanium alloys[M] ∥Polmear I, Stjohn D, Nie J F, et al. Light alloys. Netherlands: Elsevier, 2017: 369- 460.

[19] 张霜银, 林鑫, 陈静, 等. 工艺参数对激光快速成形TC4钛合金组织及成形质量的影响[J]. 稀有金属材料与工程, 2007, 36(10): 1839-1843.

[20] 张启良. TC4钛合金激光焊接工艺优化及接头组织性能研究[D]. 呼和浩特: 内蒙古工业大学, 2014.

Zhang QL. Welding process optimization and research on microstructure and properties FNR laser weld joints of TC4 Titanium alloy[D]. Hohhot: Inner Mongolia University of Technology, 2014.

[21] 姚化山, 史玉升, 章文献, 等. 金属粉末选区激光熔化成形过程温度场模拟[J]. 应用激光, 2007, 27(6): 456-460.

[22] 崔忠圻, 覃耀春. 金属学与热处理[M]. 2版. 北京: 机械工业出版社, 1989.

Cui ZY, Yan YC. Metallurgy and heat treatment[M]. 2nd ed. Beijing: Mechanical Industry Press, 2009.

[25] 曹楚南. 腐蚀电化学原理[M]. 3版. 北京: 化学工业出版社, 2008.

Cao CN. Principles of electrochemistry of corrosion[M]. 3rd ed. Beijing: Chemical Industry Press, 2008.

[28] 曹楚南, 张鉴清. 电化学阻抗谱导论[M]. 北京: 科学出版社, 2002.

Cao CN, Zhang JQ. An introduction to electrochemical impedance spectroscopy[M]. Beijing: Science Press, 2002.

[29] SatoN. Basics of corrosion chemistry[M] ∥Sato N. Green corrosion chemistry and engineering. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA, 2011: 1- 32.

[30] Newman R. Pitting corrosion of metals[J]. The Electrochemical Society Interface, 2010, 19(1): 33-38.

[31] 王海杰, 王佳, 彭欣, 等. 钛合金在3.5%NaCl溶液中的腐蚀行为[J]. 中国腐蚀与防护学报, 2015, 35(1): 75-80.

Wang H J, Wang J, Peng X, et al. Corrosion behavior of three titanium alloys in 3.5%NaCl solution[J]. Journal of Chinese Society for Corrosion and Protection, 2015, 35(1): 75-80.

[32] PedeferriP. Pitting corrosion[M] ∥Pedeferri P. Corrosion science and engineering. Cham: Springer, 2018: 207- 230.

[34] Shoesmith DW, Noël JJ. Corrosion of titanium and its alloys[M] ∥Shoesmith D W, Noël J J. Shreir's corrosion. Netherlands: Elsevier, 2010: 2042- 2052.

[35] PourbaixM, Staehle RW. Lectures on electrochemical corrosion[M]. Boston, MA: Springer US, 1973.

[36] Schmuckler J S. Oxidation reduction electrochemistry[J]. Journal of Chemical Education, 1981, 58(5): 404.

冯晓甜, 顾宏, 周圣丰, 雷剑波. 送粉式激光增材制造TC4钛合金熔覆层组织及电化学腐蚀行为的研究[J]. 中国激光, 2019, 46(3): 0302003. Xiaotian Feng, Hong Gu, Shengfeng Zhou, Jianbo Lei. Microstructure and Electrochemical Corrosion Behavior of TC4 Titanium Alloy Cladding Layer Prepared with Powder Feeding Laser Additive Manufacturing[J]. Chinese Journal of Lasers, 2019, 46(3): 0302003.