[1] 涂义, 张永忠, 席明哲. 不锈钢表面激光熔覆镍基合金层研究[J]. 稀有金属, 2008, 32(5): 598-604.

涂义, 张永忠, 席明哲. 不锈钢表面激光熔覆镍基合金层研究[J]. 稀有金属, 2008, 32(5): 598-604.

Tu Y, Zhang Y Z, Xi M Z. Investigation of nickel-based alloys coatings on stainless steel by laser cladding[J]. Chinese Journal of Rare Metals, 2008, 32(5): 598-604.

Tu Y, Zhang Y Z, Xi M Z. Investigation of nickel-based alloys coatings on stainless steel by laser cladding[J]. Chinese Journal of Rare Metals, 2008, 32(5): 598-604.

[2] HeH,

Wang DS,

Liang EJ,

et al. Improvement on microstructure and

cracking susceptibility of laser-clad Ni-based layers by in situ generation of tantalum carbides and

borides[J]. Advanced MaterialsResearch,

2012,

472/473/474/475:

239-

245.

HeH,

Wang DS,

Liang EJ,

et al. Improvement on microstructure and

cracking susceptibility of laser-clad Ni-based layers by in situ generation of tantalum carbides and

borides[J]. Advanced MaterialsResearch,

2012,

472/473/474/475:

239-

245.

[3] Wang D S, Liang E J, Chao M J, et al. Investigation on the microstructure and cracking susceptibility of laser-clad V2O5 /NiCrBSiC alloy coatings[J]. Surface and Coatings Technology, 2008, 202(8): 1371-1378.

Wang D S, Liang E J, Chao M J, et al. Investigation on the microstructure and cracking susceptibility of laser-clad V2O5 /NiCrBSiC alloy coatings[J]. Surface and Coatings Technology, 2008, 202(8): 1371-1378.

[4] 胡木林, 谢长生, 祝柏林, 等. 多道搭接激光熔覆镍基合金中裂纹断口形貌研究[J]. 材料热处理学报, 2001, 22(2): 23-26.

胡木林, 谢长生, 祝柏林, 等. 多道搭接激光熔覆镍基合金中裂纹断口形貌研究[J]. 材料热处理学报, 2001, 22(2): 23-26.

Hu M L, Xie C S, Zhu B L, et al. Fractography study on the cracking behavior of laser-clad multitrack coatings[J]. Transactions of Materials and Heat Treatment, 2001, 22(2): 23-26.

Hu M L, Xie C S, Zhu B L, et al. Fractography study on the cracking behavior of laser-clad multitrack coatings[J]. Transactions of Materials and Heat Treatment, 2001, 22(2): 23-26.

[5] 曹亚男, 张艳梅, 揭晓华, 等. 钢表面激光熔覆镍基合金涂层裂纹控制的研究[J]. 热加工工艺, 2012, 41(18): 133-136.

曹亚男, 张艳梅, 揭晓华, 等. 钢表面激光熔覆镍基合金涂层裂纹控制的研究[J]. 热加工工艺, 2012, 41(18): 133-136.

Cao Y N, Zhang Y M, Jie X H, et al. Study on control of crack in laser cladding Ni-based coating on steel[J]. Hot Working Technology, 2012, 41(18): 133-136.

Cao Y N, Zhang Y M, Jie X H, et al. Study on control of crack in laser cladding Ni-based coating on steel[J]. Hot Working Technology, 2012, 41(18): 133-136.

[6] Zhou S F, Zeng X Y, Hu Q W, et al. Analysis of crack behavior for Ni-based WC composite coatings by laser cladding and crack-free realization[J]. Applied Surface Science, 2008, 255(5): 1646-1653.

Zhou S F, Zeng X Y, Hu Q W, et al. Analysis of crack behavior for Ni-based WC composite coatings by laser cladding and crack-free realization[J]. Applied Surface Science, 2008, 255(5): 1646-1653.

[7] Yu T, Deng Q L, Dong G, et al. Effects of Ta on microstructure and microhardness of Ni based laser clad coating[J]. Applied Surface Science, 2011, 257(11): 5098-5103.

Yu T, Deng Q L, Dong G, et al. Effects of Ta on microstructure and microhardness of Ni based laser clad coating[J]. Applied Surface Science, 2011, 257(11): 5098-5103.

[8] 皮政清, 邱长军, 樊湘芳. 激光熔覆CoNiCrWC复合涂层裂纹的控制研究[J]. 稀有金属材料与工程, 2011, 40(S2): 283-285.

皮政清, 邱长军, 樊湘芳. 激光熔覆CoNiCrWC复合涂层裂纹的控制研究[J]. 稀有金属材料与工程, 2011, 40(S2): 283-285.

Pi Z Q, Qiu C J, Fan X F. Study of crack control for CoNiCrWC composite coating by laser cladding[J]. Rare Metal Materials and Engineering, 2011, 40(S2): 283-285.

Pi Z Q, Qiu C J, Fan X F. Study of crack control for CoNiCrWC composite coating by laser cladding[J]. Rare Metal Materials and Engineering, 2011, 40(S2): 283-285.

[9] 董刚, 严彪, 邓琦林, 等. 合金成分对镍基合金激光熔覆涂层组织与性能的影响[J]. 材料科学与工程学报, 2011, 29(2): 167-172.

董刚, 严彪, 邓琦林, 等. 合金成分对镍基合金激光熔覆涂层组织与性能的影响[J]. 材料科学与工程学报, 2011, 29(2): 167-172.

Dong G, Yan B, Deng Q L, et al. Effects of the alloy composition on the microstructure and properties of laser cladding Ni-based alloy coatings[J]. Journal of Materials Science and Engineering, 2011, 29(2): 167-172.

Dong G, Yan B, Deng Q L, et al. Effects of the alloy composition on the microstructure and properties of laser cladding Ni-based alloy coatings[J]. Journal of Materials Science and Engineering, 2011, 29(2): 167-172.

[10] 邓德伟, 孙晋华, 王鑫林, 等. 激光功率对激光熔覆镍基合金涂层组织与性能的影响[J]. 稀有金属, 2016, 40(1): 20-25.

邓德伟, 孙晋华, 王鑫林, 等. 激光功率对激光熔覆镍基合金涂层组织与性能的影响[J]. 稀有金属, 2016, 40(1): 20-25.

Deng D W, Sun J H, Wang X L, et al. Laser power effect on microstructure and property of laser cladding nickel based alloy coating[J]. Chinese Journal of Rare Metals, 2016, 40(1): 20-25.

Deng D W, Sun J H, Wang X L, et al. Laser power effect on microstructure and property of laser cladding nickel based alloy coating[J]. Chinese Journal of Rare Metals, 2016, 40(1): 20-25.

[11] 袁庆龙, 冯旭东, 曹晶晶, 等. 激光熔覆镍基合金涂层微观组织研究[J]. 中国激光, 2010, 37(8): 2116-2120.

袁庆龙, 冯旭东, 曹晶晶, 等. 激光熔覆镍基合金涂层微观组织研究[J]. 中国激光, 2010, 37(8): 2116-2120.

Yuan Q L, Feng X D, Cao J J, et al. Research on microstructure of Ni-based alloy coating by laser cladding[J]. Chinese Journal of Lasers, 2010, 37(8): 2116-2120.

Yuan Q L, Feng X D, Cao J J, et al. Research on microstructure of Ni-based alloy coating by laser cladding[J]. Chinese Journal of Lasers, 2010, 37(8): 2116-2120.

[12] 陈静, 杨海欧, 李延民, 等. 激光快速成形过程中熔覆层的两种开裂行为及其机理研究[J]. 应用激光, 2002, 22(3): 300-304.

陈静, 杨海欧, 李延民, 等. 激光快速成形过程中熔覆层的两种开裂行为及其机理研究[J]. 应用激光, 2002, 22(3): 300-304.

Chen J, Yang H O, Li Y M, et al. The research on two kinds of cracking behavior and mechanism of cladding in rapid laser forming process[J]. Applied Laser, 2002, 22(3): 300-304.

Chen J, Yang H O, Li Y M, et al. The research on two kinds of cracking behavior and mechanism of cladding in rapid laser forming process[J]. Applied Laser, 2002, 22(3): 300-304.

[13] 宋建丽, 邓琦林, 葛志军, 等. 镍基合金激光快速成形裂纹控制技术[J]. 上海交通大学学报, 2006, 40(3): 548-552.

宋建丽, 邓琦林, 葛志军, 等. 镍基合金激光快速成形裂纹控制技术[J]. 上海交通大学学报, 2006, 40(3): 548-552.

Song J L, Deng Q L, Ge Z J, et al. The cracking control technology of laser rapid forming nickel-based alloys[J]. Journal of Shanghai Jiaotong University, 2006, 40(3): 548-552.

Song J L, Deng Q L, Ge Z J, et al. The cracking control technology of laser rapid forming nickel-based alloys[J]. Journal of Shanghai Jiaotong University, 2006, 40(3): 548-552.

[14] 姚成武, 徐滨士, 黄坚, 等. 铁基合金激光熔覆层裂纹控制的组织设计[J]. 中国表面工程, 2010, 23(3): 74-79, 83.

姚成武, 徐滨士, 黄坚, 等. 铁基合金激光熔覆层裂纹控制的组织设计[J]. 中国表面工程, 2010, 23(3): 74-79, 83.

Yao C W, Xu B S, Huang J, et al. Microstructure design of controlling crack of Fe-based laser cladding layer[J]. China Surface Engineering, 2010, 23(3): 74-79, 83.

Yao C W, Xu B S, Huang J, et al. Microstructure design of controlling crack of Fe-based laser cladding layer[J]. China Surface Engineering, 2010, 23(3): 74-79, 83.

[15] 钟敏霖, 刘文今. Stellite和NiCrSiB合金激光送粉熔覆裂纹倾向的比较研究[J]. 中国激光, 2002, 29(11): 1031-1036.

钟敏霖, 刘文今. Stellite和NiCrSiB合金激光送粉熔覆裂纹倾向的比较研究[J]. 中国激光, 2002, 29(11): 1031-1036.

Zhong M L, Liu W J. Comparative research on cracking tendency in powder feeding laser cladding Stellite and NiCrSiB alloys[J]. Chinese Journal of Lasers, 2002, 29(11): 1031-1036.

Zhong M L, Liu W J. Comparative research on cracking tendency in powder feeding laser cladding Stellite and NiCrSiB alloys[J]. Chinese Journal of Lasers, 2002, 29(11): 1031-1036.

[16] 余廷, 邓琦林, 董刚, 等. 钽对激光熔覆镍基涂层的裂纹敏感性及力学性能的影响[J]. 机械工程学报, 2011, 47(22): 25-30.

余廷, 邓琦林, 董刚, 等. 钽对激光熔覆镍基涂层的裂纹敏感性及力学性能的影响[J]. 机械工程学报, 2011, 47(22): 25-30.

Yu T, Deng Q L, Dong G, et al. Influence of Ta on crack susceptibility and mechanical properties of laser clad Ni-based coating[J]. Journal of Mechanical Engineering, 2011, 47(22): 25-30.

Yu T, Deng Q L, Dong G, et al. Influence of Ta on crack susceptibility and mechanical properties of laser clad Ni-based coating[J]. Journal of Mechanical Engineering, 2011, 47(22): 25-30.

[17] 李美艳, 韩彬, 蔡春波, 等. 激光熔覆镍基合金温度场和应力场数值模拟[J]. 焊接学报, 2015, 36(5): 25-28.

李美艳, 韩彬, 蔡春波, 等. 激光熔覆镍基合金温度场和应力场数值模拟[J]. 焊接学报, 2015, 36(5): 25-28.

Li M Y, Han B, Cai C B, et al. Numerical simulation on temperature and stress fields of laser cladded Ni-based coating[J]. Transactions of the China Welding Institution, 2015, 36(5): 25-28.

Li M Y, Han B, Cai C B, et al. Numerical simulation on temperature and stress fields of laser cladded Ni-based coating[J]. Transactions of the China Welding Institution, 2015, 36(5): 25-28.

[18] Kadolkar P B. Watkins T R, de Hosson J T M, et al. State of residual stress in laser-deposited ceramic composite coatings on aluminum alloys[J]. Acta Materialia, 2007, 55(4): 1203-1214.

Kadolkar P B. Watkins T R, de Hosson J T M, et al. State of residual stress in laser-deposited ceramic composite coatings on aluminum alloys[J]. Acta Materialia, 2007, 55(4): 1203-1214.

[19] 陈志坤, 刘敏, 曾德长, 等. 激光熔覆裂纹的产生原因及消除方法探究[J]. 激光杂志, 2009, 30(1): 55-57.

陈志坤, 刘敏, 曾德长, 等. 激光熔覆裂纹的产生原因及消除方法探究[J]. 激光杂志, 2009, 30(1): 55-57.

Chen Z K, Liu M, Zeng D C, et al. Research on formation causes and elimination methods of the laser cladding cracks[J]. Laser Journal, 2009, 30(1): 55-57.

Chen Z K, Liu M, Zeng D C, et al. Research on formation causes and elimination methods of the laser cladding cracks[J]. Laser Journal, 2009, 30(1): 55-57.

[20] 张佳虹, 孙荣禄. 激光熔覆Ni基复合涂层气孔及裂纹敏感性的研究[J]. 热加工工艺, 2015, 44(4): 141-144.

张佳虹, 孙荣禄. 激光熔覆Ni基复合涂层气孔及裂纹敏感性的研究[J]. 热加工工艺, 2015, 44(4): 141-144.

Zhang J H, Sun R L. Research on porosity and cracking sensitivity of Ni-based composite coating by laser cladding[J]. Hot Working Technology, 2015, 44(4): 141-144.

Zhang J H, Sun R L. Research on porosity and cracking sensitivity of Ni-based composite coating by laser cladding[J]. Hot Working Technology, 2015, 44(4): 141-144.

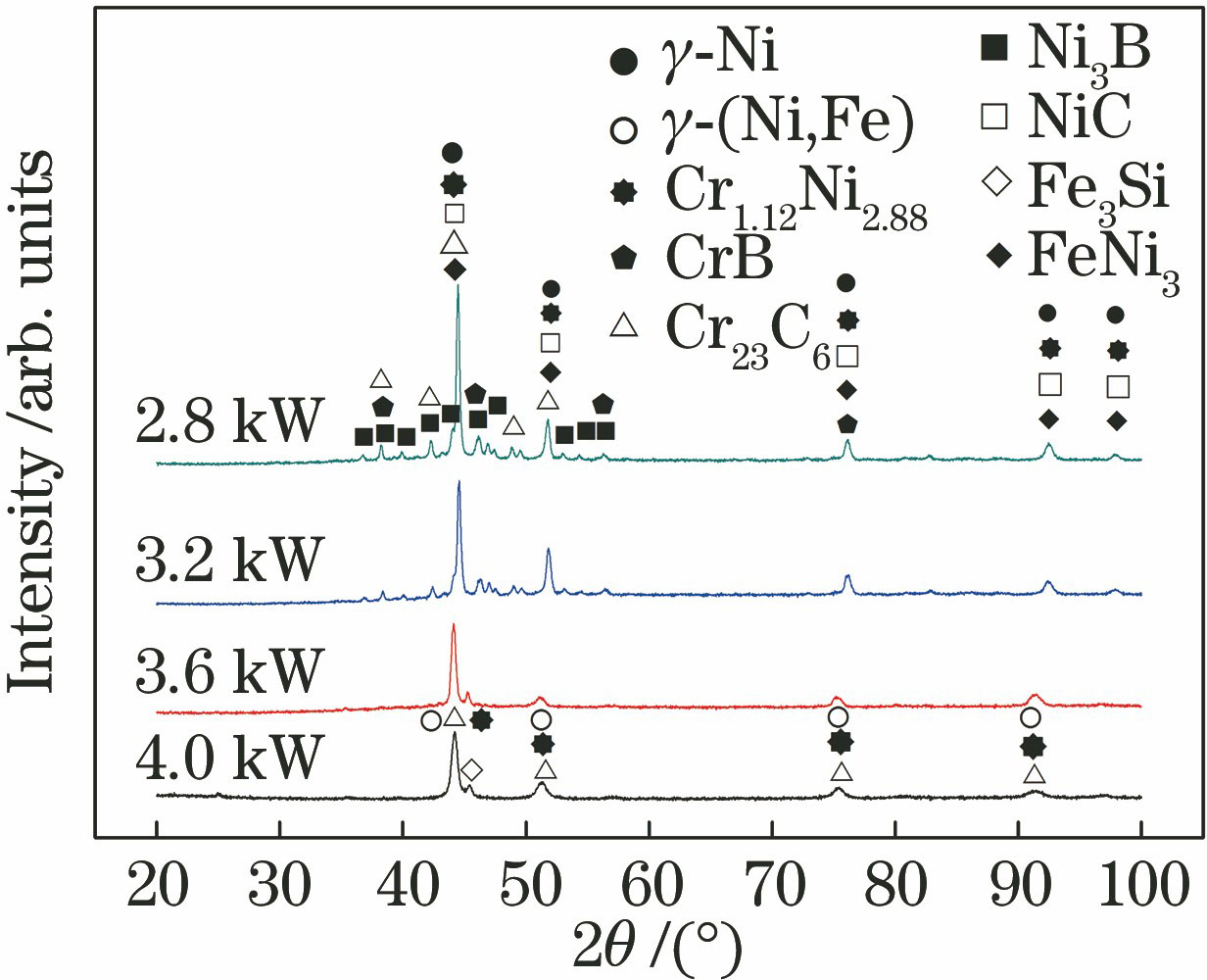

[21] 郑启池, 金亚娟, 李瑞峰, 等. 功率输入对激光熔覆镍基涂层组织和裂纹生成的影响[J]. 江苏科技大学学报(自然科学版), 2017, 31(3): 293-297.

郑启池, 金亚娟, 李瑞峰, 等. 功率输入对激光熔覆镍基涂层组织和裂纹生成的影响[J]. 江苏科技大学学报(自然科学版), 2017, 31(3): 293-297.

Zheng Q C, Jin Y J, Li R F, et al. Effect of power input on microstructure and crack formation of Ni based coating by laser cladding[J]. Journal of Jiangsu University of Science and Technology(Natural Science Edition), 2017, 31(3): 293-297.

Zheng Q C, Jin Y J, Li R F, et al. Effect of power input on microstructure and crack formation of Ni based coating by laser cladding[J]. Journal of Jiangsu University of Science and Technology(Natural Science Edition), 2017, 31(3): 293-297.

[22] 陈茹, 虞钢, 何秀丽, 等. 38MnVS6钢中硫元素扩散对激光熔覆涂层形貌和组织的影响[J]. 中国激光, 2018, 45(6): 0602005.

陈茹, 虞钢, 何秀丽, 等. 38MnVS6钢中硫元素扩散对激光熔覆涂层形貌和组织的影响[J]. 中国激光, 2018, 45(6): 0602005.

Chen R, Yu G, He X L, et al. Effect of sulfur diffusion in 38MnVS6 steel on morphology and microstructure of laser cladding layers[J]. Chinese Journal of Lasers, 2018, 45(6): 0602005.

Chen R, Yu G, He X L, et al. Effect of sulfur diffusion in 38MnVS6 steel on morphology and microstructure of laser cladding layers[J]. Chinese Journal of Lasers, 2018, 45(6): 0602005.

[23] 王东升, 于志青, 晁明举, 等. V2O5和工艺参数对镍基合金激光熔覆层裂纹敏感性的影响[J]. 激光杂志, 2005, 26(6): 81-82, 84.

王东升, 于志青, 晁明举, 等. V2O5和工艺参数对镍基合金激光熔覆层裂纹敏感性的影响[J]. 激光杂志, 2005, 26(6): 81-82, 84.

Wang D S, Yu Z Q, Chao M J, et al. Effect of laser cladding techniques and component of alloy on the cracking susceptibility of V2O5/NiCrBSiC coatings[J]. Laser Journal, 2005, 26(6): 81-82, 84.

Wang D S, Yu Z Q, Chao M J, et al. Effect of laser cladding techniques and component of alloy on the cracking susceptibility of V2O5/NiCrBSiC coatings[J]. Laser Journal, 2005, 26(6): 81-82, 84.

[24] 曾大文, 谢长生. 激光熔池三维非稳态对流传热过程的数值模拟[J]. 激光技术, 2002, 26(2): 102-105.

曾大文, 谢长生. 激光熔池三维非稳态对流传热过程的数值模拟[J]. 激光技术, 2002, 26(2): 102-105.

Zeng D W, Xie C S. Numerical simulation for the process of 3D transient convection and heat transfer in the molten pool[J]. Laser Technology, 2002, 26(2): 102-105.

Zeng D W, Xie C S. Numerical simulation for the process of 3D transient convection and heat transfer in the molten pool[J]. Laser Technology, 2002, 26(2): 102-105.

下载: 1080次

下载: 1080次