Technical development has largely depended on metal materials for thousands of years. It is known that metals are virtually perfect reflectors from the visible to the infrared in a broad range of the sunlight spectrum. Recently, the formation of surface micro-groove or microcolumn structures covered with nanostructures have been reported, produced by ultrafast laser pulses ablation that can turn metal surfaces into strong broadband light absorptive ones[1–4" target="_self" style="display: inline;">–4]. Ultrafast laser treatment of metals with strong broadband absorption may find a wide range of applications in stealth technology, broadband thermal radiation sources, radiative heat transfer devices, and solar energy harnessing[4]. On the other hand, metal materials are also known as “high-energy interfaces” and nearly any liquid spreads on its surface[5]. However, the wettability of a metal surface can be greatly modified to become “superhydrophobic,” which requires contact angles (CAs) higher than 150°, a low sliding angle (SA), and low contact angle hysteresis (CAH)[6] by nanostructuring through various methods[7–11" target="_self" style="display: inline;">–11]. In those methods, a coating of low-surface-energy organic material[810" target="_self" style="display: inline;">–10] or patterning nanostructured organic polymers[11] on a rough metal surface is generally required. Metallic surfaces with superhydrophobicity would be of great significance for both self-cleaning and antisepsis of metals, which can greatly improve their performance, particularly for those cases when a metal is used in natural and adverse environments.

Motivated by great application of multifunctional surfaces that integrate anti-reflection and superhydrophobicity, researchers have already realized multi-functional surfaces in silicon[12,13] and glass[14]. Similarly, a great change/improvement on the light absorption and wettability of a metal through surface texturing is essential for a better application of a metal material. In fact, metals that integrate both features are strongly desired by several kinds of devices; a typical example is in solar energy harnessing[3,15]. Up to now, metal surfaces either with a modified optical or wetting properties through forming nano- and microscale structures have been deeply investigated separately; however, a systematic research of realization of multifunctional metal surfaces through texturing by the use of lasers has not been reported yet. Furthermore, because organic materials are not as robust as metals in terms of chemical and mechanical stability in harsh environments[13], a multifunctional structured metal surface free from organic material coating is highly desirable for practical applications.

In this Letter, we report one-step formation of multifunctional nano- and microscale structures on aluminum (Al) and nickel (Ni) surfaces by focused femtosecond laser scanning. Al and Ni have been selected because, as essential engineering materials, they are used in many industrial applications. Our experimental results show that superhydrophobic surfaces, together with high wideband optical absorption, have been obtained on metals by the formation of nano- and microscale structures. Two years after processing, the samples still show good superhydrophobic performance. As a demonstrative application of the multifunctional metal, by attaching the femtosecond-laser-processed Al foil to the surface of solar-driven thermoelectric generator (TEG), the output power is enhanced to around 12 times over the case of a naked TEG module or the module attached with an untreated Al foil.

The laser used in the work is an amplified Ti:sapphire femtosecond laser system that generates a pulse energy of 3.5 mJ with temporal duration of 50 fs at a 1 kHz repetition rate with the central wavelength of 800 nm. A linearly polarized femtosecond laser beam is focused onto the sample surface at normal incidence by a lens of focal length of 200 mm. We chose the alloy Al and Ni as sample in this work, because they are candidate materials in solar thermal applications[3,16]. In the work, the sample is moved in the –plane by a motor-controlled stage while the laser beam is kept fixed. The laser beam is focused on the sample surface with diameter of around 200 μm, the moving velocity of the sample is about 4 mm/s, and total moving distance on both the - and -direction is about 100 mm, which is limited by traveling range of the stage. The fabrication time per area of the multi-functional metal is calculated to be about with 50 μm distance between two laser scan lines. Neutral density filters are used as attenuators to control the incident laser energy density on the metal surface. Scanning electron microscope (SEM) is employed to image structures induced by femtosecond laser processing. CA on surface is measured by a video optic CA instrument. The SA and CAH are measured by tilting the sample with a goniometer. The selected water droplet volume is . To evaluate the optical properties of the samples, we measure the reflectance with a spectrophotometer equipped with an integrating sphere detector (Shimadzu Inc., UV/visible/NIR spectrophotometer UV-3600). The reflectance is measured for wavelengths in the range of 200–2500 nm, in 1 nm increments to determine the reflectance at each wavelength.

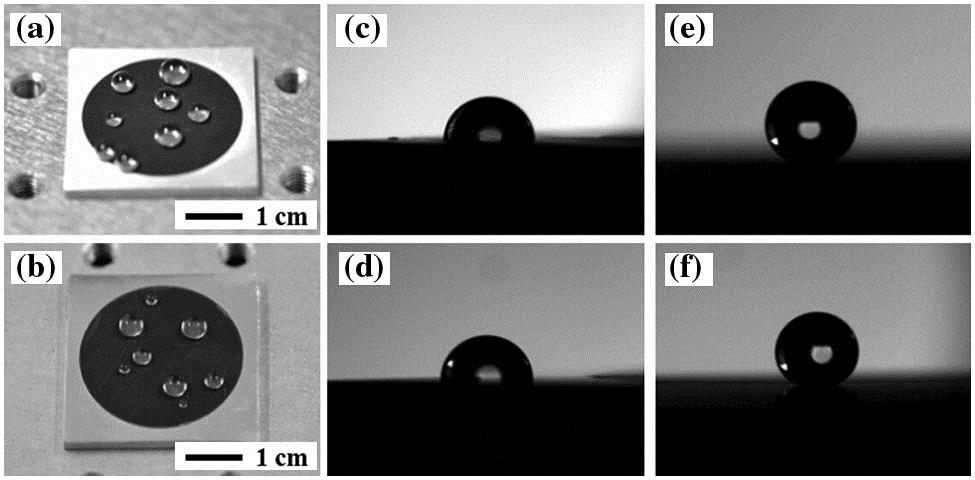

Figures 1(a) and 1(b) show images of laser-treated Al and Ni. The blackened circular area shown in Figs. 1(a) and 1(b) corresponds to the laser-treated area. One striking feature of the image is that water droplets are sitting on the laser-treated surface but do not spread as they usually do on an ordinary metal surface, exhibiting obvious lotus effect. This result indicates that the laser-treated area exhibits hydrophobicity. For quantitatively evaluating the wettability of the laser-treated sample, Figs. 1(c)–1(f) show that the CA on the original and the laser-treated surfaces of the two metals. As shown in the Fig. 1(c) for the original Al surface, the CA is 90.9°, and it increases to 155.5° with the laser-processed Al plate in Fig. 1(e). The measured SA angle of the laser-processed Al surface is 10.5° with a CAH of 0.8°. Figures 1(d) and 1(f) correspond to the case of metal Ni; the CA on flat Ni is 89.8° in Fig. 1(d) while on the treated surface in Fig. 1(f) is 161.3°. The measured SA and CAH for Ni are 14.5° and 0.6°, respectively. Compared with the original surface of both metals, the CAs of the treated Al and Ni surfaces are improved dramatically by 71% and 78%, respectively.

Fig. 1. Laser-treated Al and Ni plates exhibit lotus effect for water regarding multiple random droplets on the laser-treated (a) Al and (b) Ni plates; measured CA of original (c) Al and (d) Ni plates; measured CA of femtosecond-laser-treated (e) Al and (f) Ni plates.

下载图片 查看所有图片

The blackened appearance of the laser-treated metal surface suggest they exhibit strong light absorption in the visible range. A further investigation of the femtosecond-laser-treated metals shows that their optical properties have been greatly changed. Figure 2 shows the dependence of reflectance on wavelength from 0.2 to 2.5 μm, which displays that the reflectance of the sample surface is greatly reduced after the laser processing. Reflectance reduction of the treated metal surface is pronounced as light wavelength decreases. The measured reflectivity of prior to and after laser processing the metals surface show that this process turns both Al and Ni metals from high-reflective ones to strong light absorbers in the most intense radiation region of the solar spectrum.

Fig. 2. Wavelength-dependent reflectance of samples surfaces before and after femtosecond laser processing.

下载图片 查看所有图片

The wettability and optical property change of the laser-treated metal surface should be mainly attributed to the combined structures formation by the femtosecond laser ablation. Figure 3 shows typical surface patterns of the modified surfaces of Al and Ni. The laser fluence used in the Al and Ni sample are 0.67 and , respectively. It has been found that uniform microcolumns are formed on the surfaces. The microcolumns on modified surface of Ni are sharper and narrower than the ones on Al as observed in Figs. 3(a) and 3(c), respectively. Furthermore, Figs. 3(b) and 3(d) show that there are a large amount of nano- and microscale aggregates of nanoparticles that fuse together on the column surfaces. Figure 4 gives size (diameter) distribution histograms of the column structures corresponding to the SEM images of the Al and Ni samples in Fig. 3. As shown in Fig. 4, the diameter of the columns on the Ni sample surface ranges from 5 to 20 μm, and with a high distribution in the range from 10 to 15 μm. On the other hand, the diameter of the column structures on the Al surface is generally larger than that of the Ni sample, which corresponds to diameters ranging from 15 to 30 μm. To meet the requirement of a multi-functional metal surface that simultaneously exhibits a strong light absorption and self-cleaning, laser fluence has to be optimized. For example, in the case of Al sample, if we reduce the laser fluence to , the metal surface is full of nanoscale structures as shown in Fig. 5, and it exhibits a golden surface, indicating a significant reduction of light absorption ability[17]. The wettability property of this nanoscale structure shows that it corresponds to a CA of 148.3°, but at the same time has a very large SA of 43.5°. This result indicates that the obtained Al sample with nanoscale-structured surface for such laser parameters does not qualify as either a light absorption or a self-cleaning surface. Therefore, by simultaneously evaluating optical absorption and wettability of the laser-treated metal surface, we can optimize laser influence for multi-functional metal fabrication.

Fig. 3. SEM images of modified surfaces of Al and Ni by femtosecond laser: (a) and (b) for Al; (c) and (d) for Ni.

下载图片 查看所有图片

Fig. 4. Size distribution of mirocolumns on laser-treated Al and Ni surfaces.

下载图片 查看所有图片

Fig. 5. (a) Photo and (b) SEM image of nanoscale surface structures, Al sample.

下载图片 查看所有图片

A combination of nano- and microstructures on surfaces is considered to play a major role in the superhydrophobicity of the laser-treated metal. According to Cassie’s model describing the wetting of inhomogeneous surfaces, a rough solid surface can maintain a composite interface (liquid–air–solid) formed by trapped air between a water drop and a solid, inducing superhydrophobicity by partial sitting of a water drop on air. Micro- and submicron double-scale structures, as shown in Fig. 3, provide two trapping sites for air, between the cavities in the random nanostructure array as well as in the microcolumn array. Such surfaces possessing hierarchical nano- and microstructures exhibit controlled double-scale roughness, qualitatively much like the water repellent characteristics of the natural lotus leaf[18,19]. It is interesting to note that similar superhydrophobic metallic surfaces, that is attributed to finely controlled hierarchical surface morphology, having also been built by use of wire electric discharge machining method, in which a treatment with low-energy material coating for the superhydrophobicity has not been involved[20,21]. Figure 6 shows a cross sectional SEM image of the laser-treated Al sample, and simultaneous element composition comparison between the positions of the laser-generated structural surface and the untreated area by use of energy dispersion spectroscopy (EDS). Figure 6 shows that there is a large amount of oxygen deposited on the structural surface after laser treatment, and the oxygen deposition originates from the oxidation of aluminum in multi-pulse femtosecond laser ablation in air[22]. In the meantime, we note that previous work on wettability of the Al surface shows that a low-energy material coating on the structured surface of aluminum oxide is a necessary step to obtain superhydrophobicity[9]. Therefore, we believe that the laser-induced dual-size surface structures in our work plays an important role in the artificial superhydrophobicity behavior.

Fig. 6. Cross sectional SEM image of the laser-treated Al sample. EDS for analyzing elemental composition represents typical results taken on the laser-generated structural surface and the untreated area (cross section of the Al sample).

下载图片 查看所有图片

Such double-scale nano- and microstructures can not only trap air, but also trap light. On one hand, because all of the wavelengths measured are much less than the depth of microstructures, multireflection in cavities formed among microcolumns can occur in all tested frequency bands[23]. Therefore, surface microstructures play an important role in the enhanced absorption[24]. On the other hand, surface plasmon resonance is another mechanism causing the absorption of light[2] and a broadening of surface plasmon absorption spectra is induced by the various sizes and shapes of the surface nanostructures[25] [Figs. 3(b) and 3(d)]. As a result of nano- and microscale structures’ formation on the surfaces, the measured reflectivity of both laser-processed Al and Ni metal shown in Fig. 2 is greatly reduced over the whole region of the solar spectrum, compared to the reflectivity of untreated metal surfaces. Therefore, micro- and submicron double-scale structure leads to the cumulative effect which integrates contribution of all these absorptive, superhydrophobic, and self-cleaning mechanisms.

The striking feature of superhydrophobicity and high-absorption ability of the femtosecond-laser-processed Al drive us to apply it to the outdoor solar-driven thermoelectric devices where a TEG module is used[15] aiming at improving TEG module efficiency through trapping more sunlight to enlarge temperature difference between the hot end and the cold end while taking advantage of the self-cleaning and antisepsis properties of the structured surface. To demonstrate that a femtosecond-laser-processed Al foil can help to increase the output of a TEG module, we use the same experimental setup in Ref. [3] and measure the output power from a TEG module attached with the laser-treated Al foil, an untreated Al foil, as well as a naked module, respectively. The result shows that, compared to a naked TEG module or a module with untreated Al foil, the laser-treated Al foil attachment can improve the output power of solar-driven TEG around 12-fold.

In conclusion, employment of femtosecond laser direct structuring of Al and Ni leads to the formation of multifunctional structural surfaces without any other ancillary processing. Metals exhibited high absorbance in a broad spectral range (200–2500 nm) and great superhydrophobicity ( for modified Al and for Ni, both with a SA less than 14.5°). The observed artificial superhydrophobic and strong wideband light absorption surfaces are attributed to the cumulative effect of the surface nano- and microstructures. Our results show that the multifunctional characteristic of the laser-treated metal can be obtained from the structures prepared by simple femtosecond laser treatment process. Moreover, the fabrication of this type of multi-functional structure can be extended from a planar surface to almost any irregular ones by femtosecond laser filament processing technology[2]. The multifunctional surfaces created in this work may improve applications of metals in thermo-photovoltaics, solar absorbers, heat transfer devices, and biological sensing, and especially the self-cleaning and antisepsis function provides an effective way to benefit the device over the course of its life in a natural environment.

Haiyan Tao, Xiaowei Song, Zuoqiang Hao, 景全 林. One-step formation of multifunctional nano- and microscale structures on metal surface by femtosecond laser[J]. Chinese Optics Letters, 2015, 13(6): 061402.

Download: 898次

Download: 898次