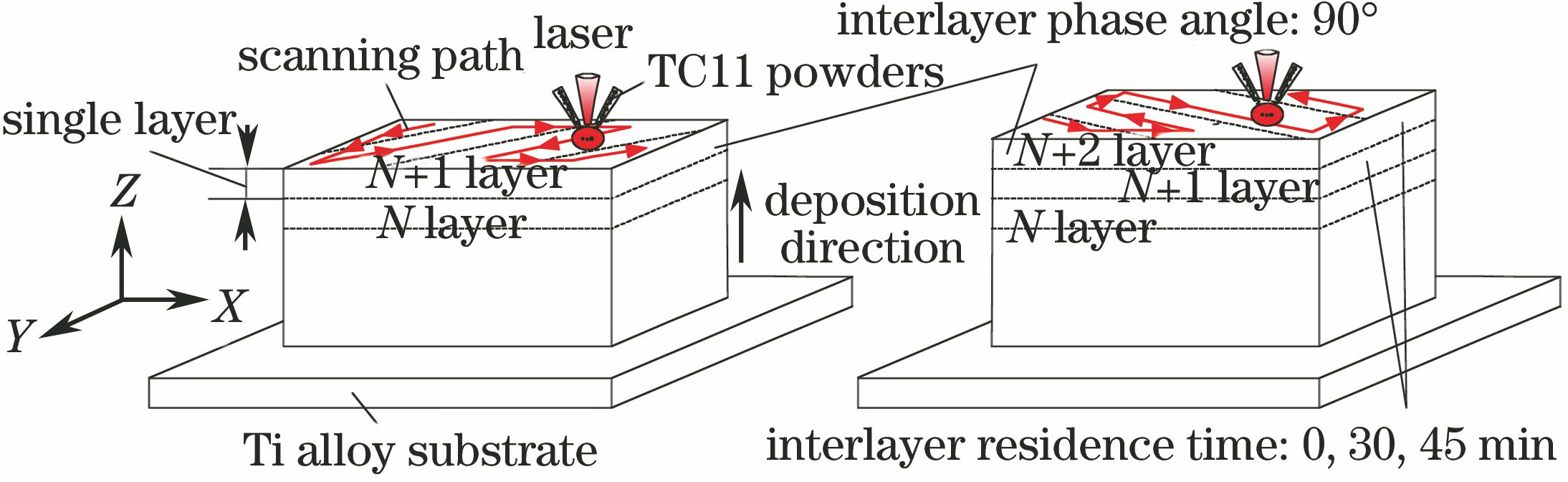

层间停留时间对激光熔化沉积TC11钛合金组织与力学性能的影响  下载: 680次

下载: 680次

严振宇, 周庆军, 侯谊飞, 杨光伟, 马存强, 王福德. 层间停留时间对激光熔化沉积TC11钛合金组织与力学性能的影响[J]. 中国激光, 2018, 45(11): 1102003.

Yan Zhenyu, Zhou Qingjun, Hou Yifei, Yang Guangwei, Ma Cunqiang, Wang Fude. Effect of Interlayer Residence Time on Microstructures and Mechanical Properties of Laser Melting Deposited TC11 Titanium Alloys[J]. Chinese Journal of Lasers, 2018, 45(11): 1102003.

[1] 席明哲, 吕超, 吴贞号, 等. 连续点式锻压激光快速成形TC11钛合金的组织和力学性能[J]. 金属学报, 2017, 53(9): 1065-1074.

[2] 黄瑜, 陈静, 张凤英, 等. 热处理对激光立体成形TC11钛合金组织的影响[J]. 稀有金属材料与工程, 2009, 38(12): 2146-2150.

[3] 赵卫强, 陈静, 杨杰穷, 等. 激光立体成形工艺对TC11钛合金组织和力学性能的影响[J]. 应用激光, 2012, 32(6): 479-483.

[7] Li A B, Huang L J, Meng Q Y, et al. Hot working of Ti-6Al-3Mo-2Zr-0.3Si alloy with lamellar α+β starting structure using processing map[J]. Materials and Design, 2009, 30(5): 1625-1631.

[8] 王华明, 张述泉, 汤海波, 等. 大型钛合金结构件激光快速成形技术研究进展[J]. 航空精密制造技术, 2008, 44(6): 28-30.

[9] 王华明. 高性能大型金属构件激光增材制造: 若干材料基础问题[J]. 航空学报, 2014, 35(10): 2690-2698.

[10] 王华明. 航空高性能金属结构件激光快速成形研究进展[J]. 航空制造技术, 2005( 12): 26- 28.

Wang HM. Research progress of laser rapid forming of aviation high-performance metal structural components[J]. Aeronautical Manufacturing Technology, 2005( 12): 26- 28.

[11] 王华明, 张述泉, 王向明. 大型钛合金结构件激光直接制造的进展与挑战[J]. 中国激光, 2009, 36(12): 3204-3209.

[12] Zhu Y Y, Tian X J, Li J, et al. Microstructure evolution and layer bands of laser melting deposition Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy[J]. Journal of Alloys and Compounds, 2014, 616: 468-474.

[13] Ren H S, Tian X J, Liu D, et al. Microstructural evolution and mechanical properties of laser melting deposited Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(6): 1856-1864.

[15] Zhu Y Y, Liu D, Tian X J, et al. Characterization of microstructure and mechanical properties of laser melting deposited Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy[J]. Materials and Design, 2014, 56: 445-453.

[17] Zhu Y Y, Li J, Tian X J, et al. Microstructure and mechanical properties of hybrid fabricated Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy by laser additive manufacturing[J]. Materials Science and Engineering: A, 2014, 607: 427-434.

[18] 贺瑞军, 王华明. 激光熔化沉积Ti-6Al-2Zr-Mo-V钛合金组织特征研究[J]. 航空材料学报, 2009, 29(6): 18-22.

[19] Li Z, Cheng X, Li J, et al. Thermal expansion properties of laser melting deposited Ti-6.5Al-2Zr-1Mo-1V alloy during α+β zone annealing[J]. Materials Characterization, 2017, 128: 115-122.

[20] Li Z, Li J, Liu J, et al. Structure and formation mechanism of α/α interface in laser melting deposited α+β titanium alloy[J]. Journal of Alloys and Compounds, 2016, 657: 278-285.

[21] 杨光, 王文东, 钦兰云, 等. 退火温度对激光沉积TA15合金组织及性能的影响[J]. 中国激光, 2016, 43(12): 1202007.

[22] 钦兰云, 徐丽丽, 杨光, 等. 退火方式对激光沉积TA15钛合金组织及力学性能的影响[J]. 中国激光, 2018, 45(3): 0302004.

[24] Liu C M, Wang H M, Tian X J, et al. Microstructure and tensile properties of laser melting deposited Ti-5Al-5Mo-5V-1Cr-1Fe near β titanium alloy[J]. Materials Science and Engineering: A, 2013, 586: 323-329.

[25] Liu C M, Wang H M, Tian X J, et al. Development of a pre-heat treatment for obtaining discontinuous grain boundary α in laser melting deposited Ti-5Al-5Mo-5V-1Cr-1Fe alloy[J]. Materials Science and Engineering: A, 2014, 604: 176-182.

严振宇, 周庆军, 侯谊飞, 杨光伟, 马存强, 王福德. 层间停留时间对激光熔化沉积TC11钛合金组织与力学性能的影响[J]. 中国激光, 2018, 45(11): 1102003. Yan Zhenyu, Zhou Qingjun, Hou Yifei, Yang Guangwei, Ma Cunqiang, Wang Fude. Effect of Interlayer Residence Time on Microstructures and Mechanical Properties of Laser Melting Deposited TC11 Titanium Alloys[J]. Chinese Journal of Lasers, 2018, 45(11): 1102003.