304不锈钢光纤激光焊接模式的影响因素  下载: 1089次

下载: 1089次

Influence Factors of Fiber Laser Welding Modes for 304 Stainless Steel

1 上海交通大学材料科学与工程学院, 上海 200240

2 上海第一机床厂有限公司, 上海 201306

图 & 表

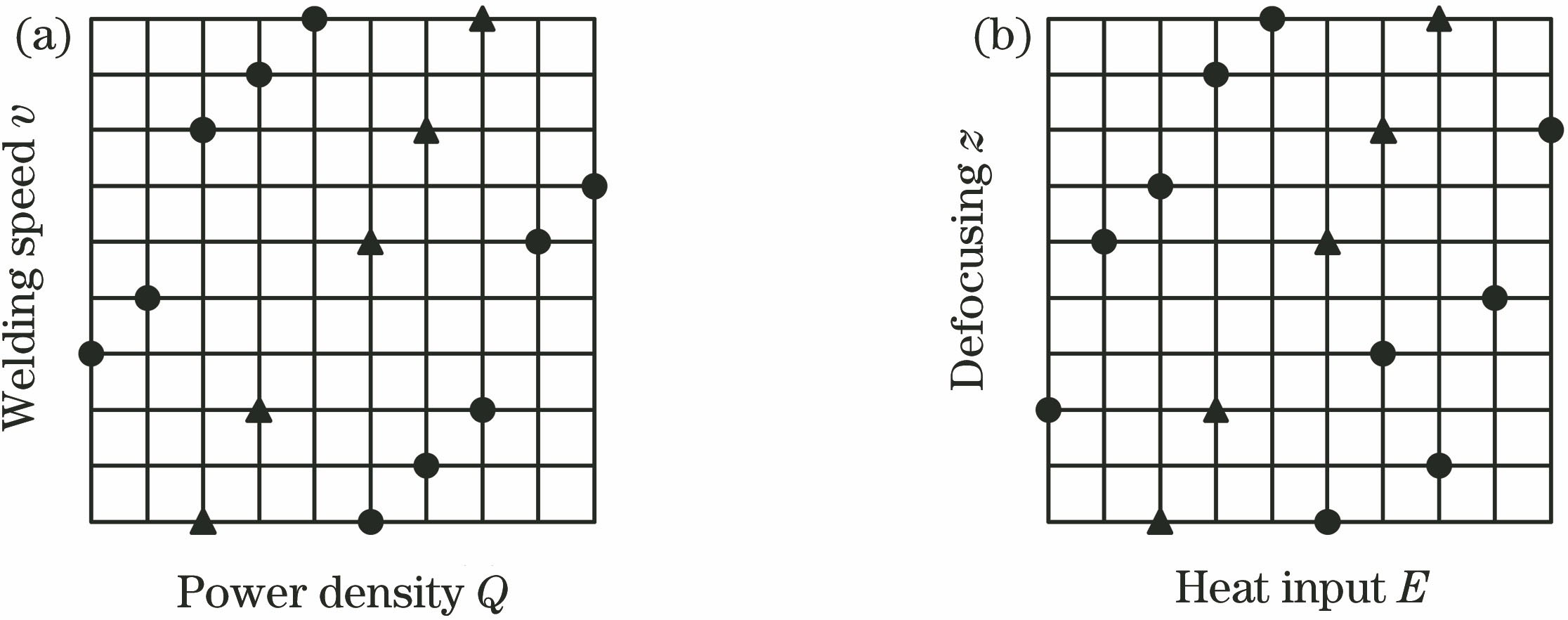

图 1. 考虑交互作用的试验点分布。(a)功率密度-焊接速度;(b)热输入-离焦量

Fig. 1. Test point distribution when interactive action included. (a) Power density-welding speed; (b) heat input-defocus distance

下载图片 查看原文

图 2. 典型的焊缝形状。(a)圆弧形;(b)三角形;(c)钉头形;(d)钉状

Fig. 2. Typical weld shapes. (a) Circular arc shape; (b) triangular shape; (c) nail head shape; (d) nail shape

下载图片 查看原文

图 3. 各因素与试验结果间的关系。(a)激光功率P;(b)焊接速度v;(c)光斑面积S;(d)功率密度Q;(e)热输入E;(f)热输入密度e

Fig. 3. Relationship between each factor and test result. (a) Laser power P; (b) welding speed v; (c) spot area S; (d) power density Q; (e) heat input E; (f) heat input density e

下载图片 查看原文

表 1单因素均匀设计试验方案

Table1. Test plan of single-factor uniform design

| TestNo. | Welding parameter | Dependent variable |

|---|

| LaserpowerP /kW | Travelspeedv /(mm·s-1) | Defocusdistancez /mm | Spot areaS /mm2 | PowerdensityQ /(105 W·cm-2) | Heat inputE / (J·mm-1) | Heat inputdensitye /(J·mm-3) |

|---|

| 1 | 1.27 | 60 | 6 | 0.492 | 2.58 | 21.17 | 43.04 | | 2 | 1.33 | 85 | 2 | 0.397 | 3.35 | 15.65 | 39.44 | | 3 | 1.42 | 55 | 9 | 0.625 | 2.27 | 25.82 | 41.28 | | 4 | 1.50 | 80 | 5 | 0.459 | 3.27 | 18.75 | 40.84 | | 5 | 1.54 | 50 | 1 | 0.388 | 3.97 | 30.80 | 79.42 | | 6 | 1.65 | 75 | 8 | 0.575 | 2.87 | 22.00 | 38.26 | | 7 | 1.74 | 45 | 4 | 0.432 | 4.02 | 38.67 | 89.43 | | 8 | 1.80 | 70 | 0 | 0.385 | 4.68 | 25.71 | 66.82 | | 9 | 1.84 | 40 | 7 | 0.530 | 3.47 | 46.00 | 86.73 | | 10 | 1.95 | 65 | 3 | 0.412 | 4.74 | 30.00 | 72.89 |

|

查看原文

表 2考虑交互作用的试验方案

Table2. Test plan when interactive action included

| TestNo. | Welding parameter | Dependent variable |

|---|

| LaserpowerP /kW | Travelspeedv /(mm·s-1) | Defocusdistancez /mm | Spot areaS /mm2 | PowerdensityQ /(105 W·cm-2) | HeatinputE / (J·mm-1) | Heat inputdensity e /(J·mm-3) |

|---|

| 11 | 1.65 | 40 | 8 | 0.575 | 2.87 | 41.25 | 71.74 | | 12 | 1.50 | 50 | 5 | 0.459 | 3.26 | 30.00 | 65.34 | | 13 | 1.84 | 65 | 7 | 0.530 | 3.47 | 28.31 | 53.37 | | 14 | 1.74 | 75 | 4 | 0.432 | 4.02 | 23.20 | 53.66 | | 15 | 1.54 | 85 | 1 | 0.388 | 3.97 | 18.12 | 46.72 | | 16 | 1.27 | 60 | 0 | 0.385 | 3.30 | 21.17 | 55.00 | | 17 | 1.65 | 75 | 2 | 0.397 | 4.16 | 22.00 | 55.45 | | 18 | 1.80 | 70 | 5 | 0.459 | 3.92 | 25.71 | 56.01 | | 19 | 1.95 | 65 | 7 | 0.530 | 3.68 | 30.00 | 56.56 | | 20 | 1.54 | 50 | 9 | 0.625 | 2.46 | 30.80 | 49.24 |

|

查看原文

表 3试验结果汇总

Table3. Summary of test results

| TestNo. | Welding parameter | Dependent variable | Type ofshape |

|---|

| LaserpowerP /kW | | Travelspeedv /(mm·s-1) | Defocusdistancez /mm | Spot areaS /mm2 | PowerdensityQ /(105 W·cm-2) | HeatinputE /(J·mm-1) | Heat inputdensitye /(J·mm-3) |

|---|

| 1 | 1.27 | 60 | 6 | 0.492 | 2.58 | 21.17 | 43.04 | Circular arc (a) | | 2 | 1.33 | 85 | 2 | 0.397 | 3.35 | 15.65 | 39.44 | Circular arc (a) | | 3 | 1.42 | 55 | 9 | 0.625 | 2.27 | 25.82 | 41.28 | Circular arc (a) | | 4 | 1.50 | 80 | 5 | 0.459 | 3.27 | 18.75 | 40.84 | Circular arc (a) | | 5 | 1.54 | 50 | 1 | 0.388 | 3.97 | 30.80 | 79.42 | Nail head (c) | | 6 | 1.65 | 75 | 8 | 0.575 | 2.87 | 22.00 | 38.26 | Circular arc (a) | | 7 | 1.74 | 45 | 4 | 0.432 | 4.02 | 38.67 | 89.43 | Nail (d) | | 8 | 1.80 | 70 | 0 | 0.385 | 4.68 | 25.71 | 66.82 | Nail head (c) | | 9 | 1.84 | 40 | 7 | 0.530 | 3.47 | 46.00 | 86.73 | Nail (d) | | 10 | 1.95 | 65 | 3 | 0.412 | 4.74 | 30.00 | 72.89 | Nail head (c) | | 11 | 1.65 | 40 | 8 | 0.575 | 2.87 | 41.25 | 71.74 | Nail head (c) | | 12 | 1.50 | 50 | 5 | 0.459 | 3.26 | 30.00 | 65.34 | Triangle (b) | | 13 | 1.84 | 65 | 7 | 0.530 | 3.47 | 28.31 | 53.37 | Triangle (b) | | 14 | 1.74 | 75 | 4 | 0.432 | 4.02 | 23.20 | 53.66 | Triangle (b) | | 15 | 1.54 | 85 | 1 | 0.388 | 3.97 | 18.12 | 46.72 | Triangle (b) | | 16 | 1.27 | 60 | 0 | 0.385 | 3.30 | 21.17 | 55.00 | Triangle (b) | | 17 | 1.65 | 75 | 2 | 0.397 | 4.16 | 22.00 | 55.45 | Triangle (b) | | 18 | 1.80 | 70 | 5 | 0.459 | 3.92 | 25.71 | 56.01 | Triangle (b) | | 19 | 1.95 | 65 | 7 | 0.530 | 3.68 | 30.00 | 56.56 | Triangle (b) | | 20 | 1.54 | 50 | 9 | 0.625 | 2.46 | 30.80 | 49.24 | Triangle (b) |

|

查看原文

冷晓春, 罗守一, 李延葆, 金伟芳. 304不锈钢光纤激光焊接模式的影响因素[J]. 激光与光电子学进展, 2018, 55(11): 111402. Xiaochun Leng, Shouyi Luo, Yanbao Li, Weifang Jin. Influence Factors of Fiber Laser Welding Modes for 304 Stainless Steel[J]. Laser & Optoelectronics Progress, 2018, 55(11): 111402.

下载: 1089次

下载: 1089次