The SG-III laser facility is the largest high-power laser facility which is being built in China for research in inertial confinement fusion[1]. Each of the 48 main laser beamlines is capable of producing an output energy of approximately 7500 J in a 3 ns pulse at the wavelength of 1053 nm, with the intensity of several gigawatts per square centimeter. As the laser pulse is propagating forward in the beam tubes, it passes through a lens, Nd glasses, a photoelectric switch, vacuum windows, and many other transmitting components. Even though there are anti-reflecting films coating the surfaces of these components, complete transmittance cannot be achieved. They act as sources of ghost reflections, creating damage to optical components which locate near ghost foci[2]. If the ghost focus is located exactly on the spatial filter pinhole, the ghost beam will be further amplified in the gain medium, increasing its own energy while decreasing the gain capacity of the main amplifier. Usually, the energy of ghost beams can be a few hundred Joules or even larger[3]; if this scale of energy is concentrated on small elements, stray light fluence will be extraordinarily high, greater than the damage threshold of the optical film (typically assumed to be ). For example, light at the fundamental wavelength (1053 nm) that is reflected from the final optics in the target chamber along the output beam path can travel backward through the pinholes in the spatial filters, experiencing considerable gain by double-passing both the power and main amplifiers. Finally, they constitute a danger to the beam reversal optics (BROs). On the other hand, stray light can easily mask the signals in the measurement system[4], bringing error in the laser energy and waveform. Therefore, regulation of back-reflection is a major concern in the design and maintenance of high-power laser facilities[57" target="_self" style="display: inline;">–7].

In recent years, many studies have been conducted to enhance the damage thresholds of optical components[810" target="_self" style="display: inline;">–10]. At the same time, other control measures, such as adding saturable absorbers, have been taken to decrease stray light to an acceptable level. Nevertheless, a fast way to pinpoint the source of backward stray light once it appears is of great importance to the safety regulation of the whole system. In the light chain of sophisticated configuration like an optical communication network, an optical time domain reflectometer (OTDR) is commonly used to locate fiber breaks or splice losses[11]. OTDR measurements are achieved by measuring the time delay between short light pulses entering the fiber and discrete changes in the back-scattered signals[12]. This locating method affords a reference to determination of the source of backward stray light in high-power laser facilities.

In this Letter, we focus on a damaging example that occurred in the SG-III laser facility. A detailed analysis of the position of the damaging spot is given at first. Then we located the source of stray light by calibrating the time sequence of the main laser and backward stray light. Results show that the accuracy of our method is 1 m. Energy of the back-reflected light is 44 times weaker after modification. Moreover, a method to monitor any of the undesired light is discussed.

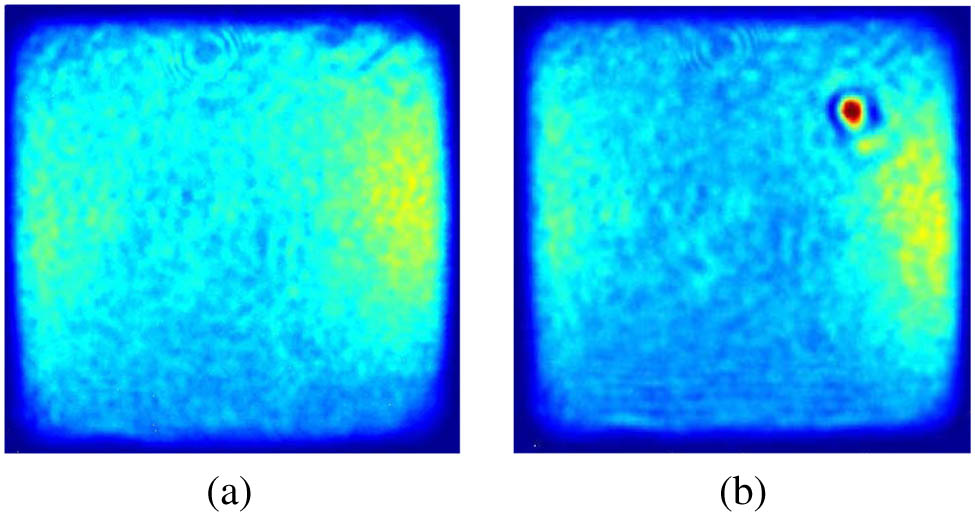

During the online operation in the SG-III laser facility, there had been an abnormal bright spot appearing on the beam near-field profile after one shot. In comparison, the near-field is still good after the preceding main shot, as shown in Fig. 1. The size of the spot is about one-tenth of the near-field size; it should be laser-induced damage on one certain optical element. Considering that the size of the beam near-field profile is 360 mm, it is unlikely that a 30 mm round-shape damaging spot could exist in large optics, so we give priority to small optical elements.

Fig. 1. Near-field profile; (a) before the damage occurs; (b) after the damage occurs.

下载图片 查看所有图片

First, we judged the position of the damage. Figure 2 is a schematic drawing of the main laser optical system of the SG-III. The main amplifier includes two spatial filters, both of which act as low-pass filters to beams that come from the cavity amplifier and power amplifier. Focusing a beam through a pinhole aperture allows removal of spatial irregularities or high-frequency components caused by nonlinear effects of amplification, dust, or imperfect optics[13]. In view of the near-field image at the output of the transport spatial filter (TSF), the details of the images become obscure. On the contrary, when the pinholes are removed from both filters, the near-field images are sharp and clean, with all the detailed information. So if only one filter is allowed to be at the working position every time and the damaging spot is obscure in the edge, then the damage must be in the optical train before this filter and vice versa. Following this principle, we analyzed the morphology of the damaging spot by making the two filters work independently, and concluded that the damage took place in the beam path before the cavity spatial filter (CSF). Considering our previous analysis that the damage is most likely on small elements, we focused our attention on the preamplifier beam transport optics (PABTS, shown in Figs. 2 and 3); five small elements are distributed in this module. After online examination, we found it is the last injection mirror IM0 in the PABTS which injects the beam from the preamplifier module (PAM) into the main amplifier (AMP) that got damaged. The damaging morphology of the IM0 is shown in Fig. 4. The damaged film is gray and irregularly shaped, distinct from its surrounding area.

Fig. 2. Schematic drawing of the main laser optical system of the SG-III.

下载图片 查看所有图片

Second, we conducted an experiment in order to find out the source of stray light. Our experimental setup is shown in Fig. 3. Two photodetectors (PDs), both of which are connected to an oscilloscope (LeCroy, United States), are located below and behind the laser injection mirror IM1. This enables the simultaneous detection of the forward-propagating beam and counter-propagating beam. Then appropriate attenuation must be chosen in front of the detectors. Too large attenuation is not good for the collection of the signal. On the other hand, if attenuation is not enough, the high intensity may saturate or even break the detector. We chose rough cloth instead of grayscale attenuator in our tests. After the preparation work, a low-energy PAM shot was first fired to ensure proper functioning of the detectors. As shown in Fig. 5, when PD2 first captured the transmission pulse signal, PD1 captured two successive pulse signals after 6 and 20 ns. The two signals correspond to the beam reflected from the mechanical structure below lens L0 and focusing lens L0, respectively. The PAM shot demonstrates that two detectors work well, yet attenuation needs to be enhanced in front of PD2.

Fig. 5. Stray light profile measured in the PAM shot.

下载图片 查看所有图片

Subsequently the main laser was fired with an output energy of 3000 J. In case of further damage, the liquid-crystal (LC) light valve in PAM was programmed to obscure laser light at the damaged location within the beam profile[14]. Results are shown in Fig. 6. Light transmitted from IM1 was not captured by PD2 due to large attenuation. PD1 captured two small reflected light signals around 100 ns, which are consistent with the results of PAM shot, and one bigger signal at 942 ns. This big additional pulse must be the amplified backward stray light that damaged IM0. The rising edge of the backward stray light can be clearly identified from Fig. 6 even though it is so strong that the whole waveform was not obtained. What was worse, the backward stray light can even propagate back into the PAM and again captured by PD2, indicated by the weak signal in the red line. According to Figs. 5 and 6, the backward stray light is calculated to be delayed 840 ns at IM1 with respect to the injection pulse; that means the starting point of the backward stray light is about 126 m away from IM1 in terms of the optical path. In the SG-III, the optoelectronic switch is designed to be 127 m from IM1, thus this place is most likely to be the source of the backward stray light.

Fig. 6. Stray light profile measured in the first main shot.

下载图片 查看所有图片

This judgment is also supported by the evidence that there is a bright spot partially covering the pinhole of TSF and the spot moves as the switch is tilted. To mitigate the problem, we laterally adjusted the posture of the switch until the whole spot went outside the pinhole, shown in Fig. 7. The result was again verified by another main shot. Figure 8 shows a reduction of 44 times for the backward stray light with the peak intensity of 0.0185 V at 956 ns; the intensity of backward stray light decreases dramatically, comparable to the intensity of the laser pulse reflected from the PABTS. However, the stray light was not completely eliminated, which implies ghost beams reflected from other surfaces also entered the pinhole. The time interval is measured to be 848 ns, equivalent to be 127 m in the optical path. This position is exactly corresponding to the position of the photoelectric switch. So the un-eliminated signal can be explained by the fact that there are three reflecting surfaces on the switch (with two windows and a switch crystal); the reflected beam of the front surface contributes to a substantial portion of the backward stray light. The optoelectronic switch was tilted once again on the guarantee that three spots were all intercepted by the pinhole. Result of another main shot demonstrates complete removal of the ghost beam before entering the pinhole significantly reduced the stray light.

Fig. 7. Back-reflected light spot on the pinhole of the spatial filter.

下载图片 查看所有图片

Fig. 8. Stray light profile measured in the second main shot.

下载图片 查看所有图片

The types of stray light in the SG-III vary according to their different origins, thus control measures differ in various types of stray light. The stray light that have been discussed previously is controlled by using the pinhole plane to block its propagation; this is realized by tilting the reflected surface in the lateral direction. Whereas in the situation where a ghost beam is reflected from a lens surface, light can expand as it travels back toward the pinhole plane. Optics need to be located outside ghost stay-out zones[2] in the axial direction to avoid potential damage. Usually, no harmful damage would occur when optics are placed at a distance more than half of the ghost foci from the ghost[15]. The result of our work shows the backward stray light can also be a potential threat to the PAM. As a pioneer, the National Ignition Facility (NIF) in the United States has included a large-size Faraday isolator after the PAM to prevent any undesired light reflected back from the main laser from entering the PAM[16]. Despite of this, a potential threat would possibly emerge when the state of the whole system is changed due to mechanical instability, surface contaminations[17], or misalignment[18]. Then it becomes a necessity that a diagnostic sensor be used to monitor the back-reflected light in case of any potential threat. Techniques needs to be further improved in our systems to ensure safety in the routine operation of the SG-III.

In conclusion, work on determining the source of harmful stray light is carried out in the SG-III laser facility. The starting point of the backward stray light is obtained with an accuracy of up to 1 m and the adjustment of the posture of the switch reduces the stray light by a factor of roughly 44. The judging method along with the control measure can be used for the removal of harmful stray light in huge laser facilities, and it can be promoted in huge laser facilities of this kind. In addition, apart from the brightest reflected spot, weak stray light is easily ignored; therefore, care must be taken that stay light is totally blocked by a spatial filter so that no light will be amplified and cause harmful damage in high-power laser facilities.

Dandan Zhou, Yuanchen Wang, Xuewei Deng, Wei Zhou, Wei Zhong, Huaiting Jia, Fan Zhang, Huaiwen Guo, 东霞 胡. Online determination of the source of stray light in the SG-III high-power laser facility[J]. Chinese Optics Letters, 2015, 13(3): 031406.

Download: 839次

Download: 839次