38MnVS6钢中硫元素扩散对激光熔覆涂层形貌和组织的影响  下载: 1037次

下载: 1037次

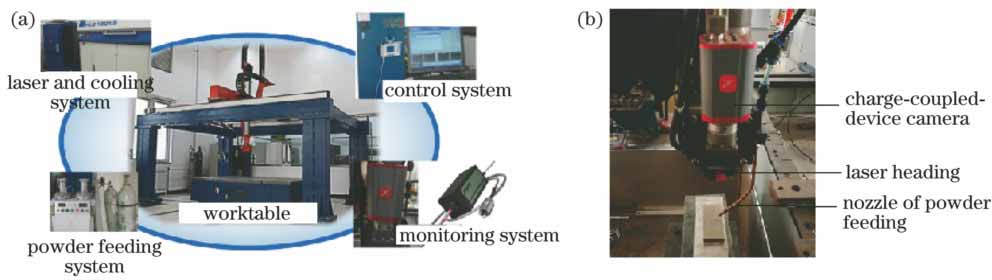

陈茹, 虞钢, 何秀丽, 甘政涛, 李少霞. 38MnVS6钢中硫元素扩散对激光熔覆涂层形貌和组织的影响[J]. 中国激光, 2018, 45(6): 0602005.

Ru Chen, Gang Yu, Xiuli He, Zhengtao Gan, Shaoxia Li. Effect of Sulfur Diffusion in 38MnVS6 Steel on Morphology and Microstructure of Laser Cladding Layers[J]. Chinese Journal of Lasers, 2018, 45(6): 0602005.

[3] 段晓溪, 高士友, 顾勇飞, 等. 激光熔覆316L+SiC的强化机制和摩擦磨损性能研究[J]. 中国激光, 2016, 43(1): 0103004.

段晓溪, 高士友, 顾勇飞, 等. 激光熔覆316L+SiC的强化机制和摩擦磨损性能研究[J]. 中国激光, 2016, 43(1): 0103004.

[9] 彭进, 王星星, 李刚, 等. 激光填丝焊对熔池动态行为及焊缝成形的影响[J]. 中国激光, 2017, 44(11): 1102004.

彭进, 王星星, 李刚, 等. 激光填丝焊对熔池动态行为及焊缝成形的影响[J]. 中国激光, 2017, 44(11): 1102004.

[13] Mills K C, Keene B J, Brooks R F, et al. Marangoni effects in welding[J]. Philosophical Transactions of the Royal Society A, 1998, 356(1739): 911-925.

Mills K C, Keene B J, Brooks R F, et al. Marangoni effects in welding[J]. Philosophical Transactions of the Royal Society A, 1998, 356(1739): 911-925.

[19] 夏胜全, 何建军, 王巍, 等. 激光深熔焊熔池三维瞬态行为数值模拟[J]. 中国激光, 2016, 43(11): 1102004.

夏胜全, 何建军, 王巍, 等. 激光深熔焊熔池三维瞬态行为数值模拟[J]. 中国激光, 2016, 43(11): 1102004.

陈茹, 虞钢, 何秀丽, 甘政涛, 李少霞. 38MnVS6钢中硫元素扩散对激光熔覆涂层形貌和组织的影响[J]. 中国激光, 2018, 45(6): 0602005. Ru Chen, Gang Yu, Xiuli He, Zhengtao Gan, Shaoxia Li. Effect of Sulfur Diffusion in 38MnVS6 Steel on Morphology and Microstructure of Laser Cladding Layers[J]. Chinese Journal of Lasers, 2018, 45(6): 0602005.