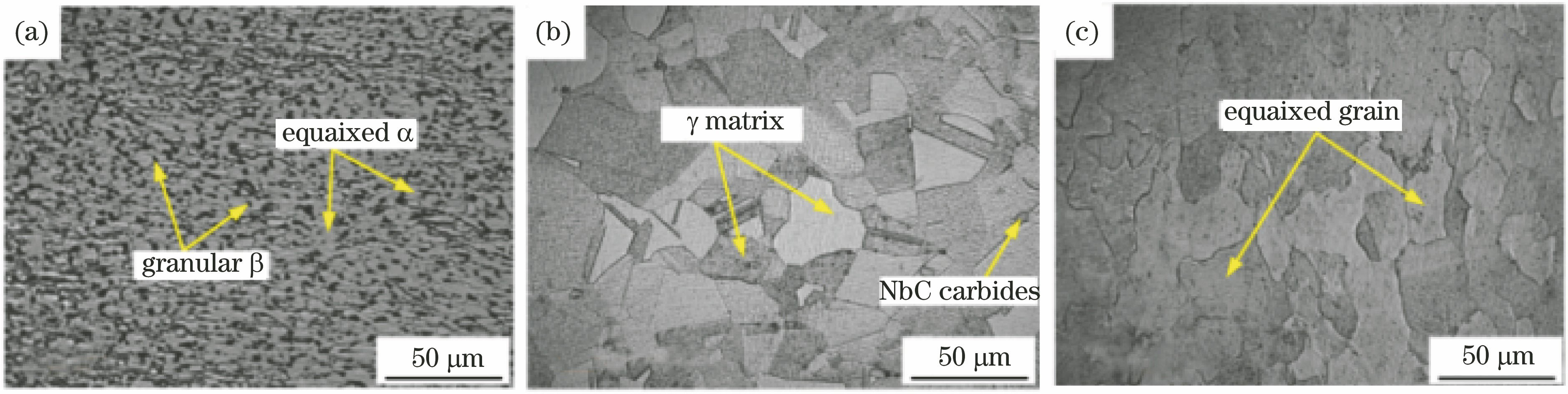

热输入对Ti6Al4V/Inconel 718激光诱导钎焊接头组织和力学性能的影响  下载: 1055次

下载: 1055次

李伦坤, 高晓龙, 刘晶, 王小强. 热输入对Ti6Al4V/Inconel 718激光诱导钎焊接头组织和力学性能的影响[J]. 中国激光, 2020, 47(5): 0502002.

Lunkun Li, Xiaolong Gao, Jing Liu, Xiaoqiang Wang. Effects of Heat Input on Microstructure and Mechanical Properties of Ti6Al4V/Inconel 718 Laser-Induced Brazing Joint[J]. Chinese Journal of Lasers, 2020, 47(5): 0502002.

[1] Shang C, Wang C Y, Xu G J, et al. Laser additive manufacturing of TA15-Inconel 718 bimetallic structure via Nb/Cu multi-interlayer[J]. Vacuum, 2019, 169: 108888.

[2] Li P, Dong H G, Xia Y Q, et al. Inhomogeneous interface structure and mechanical properties of rotary friction welded TC4 titanium alloy/316L stainless steel joints[J]. Journal of Manufacturing Processes, 2018, 33: 54-63.

[3] Gao X L, Liu J, Zhang L J, et al. Effect of the overlapping factor on the microstructure and mechanical properties of pulsed Nd∶YAG laser welded Ti6Al4V sheets[J]. Materials Characterization, 2014, 93: 136-149.

[4] Jelvani S, Shoja Razavi R, Barekat M, et al. Evaluation of solidification and microstructure in laser cladding Inconel 718 superalloy[J]. Optics & Laser Technology, 2019, 120: 105761.

[5] Cheepu M, Venkateswarlu D, Rao P N, et al. Microstructure characterization of superalloy 718 during dissimilar rotary friction welding[J]. Materials Science Forum, 2019, 969: 211-217.

[6] 张浩. TC4钛合金与Inconel 718高温合金异种金属激光焊接基础研究[D]. 武汉: 华中科技大学, 2017.

ZhangH. Basic study on dissimilar metal laser welding of TC4 and Inconel 718[D]. Wuhan: Huazhong University of Science and Technology, 2017.

[7] 邓永强. 纯钛及Ti-6Al-4V合金及其与304不锈钢及Inconel镍基合金的连接研究[D]. 重庆: 重庆大学, 2016.

Deng YQ. Investigation on the joining of CP-Ti, Ti-6Al-4V with similar and 304 stainless steel, inconel Ni-based alloy dissimilar materials[D]. Chongqing: Chongqing University, 2016.

[8] Chen B Q, Xiong H P, Sun B B, et al. Microstructures and mechanical properties of Ti3Al/Ni-based superalloy joints arc welded with Ti-Nb and Ti-Ni-Nb filler alloys[J]. Progress in Natural Science: Materials International, 2014, 24(4): 313-320.

[9] Chatterjee S, Abinandanan T A, Reddy G M, et al. Microstructure formation in dissimilar metal welds: electron beam welding of Ti/Ni[J]. Metallurgical and Materials Transactions A, 2016, 47(2): 769-776.

[10] Gao Y N, Huang L J, An Q, et al. Microstructure evolution and mechanical properties of titanium matrix composites and Ni-based superalloy joints with Cu interlayer[J]. Journal of Alloys and Compounds, 2018, 764: 665-673.

[11] Chen Y H, Mao Y Q, Lu W W, et al. Investigation of welding crack in micro laser welded NiTiNb shape memory alloy and Ti6Al4V alloy dissimilar metals joints[J]. Optics & Laser Technology, 2017, 91: 197-202.

[13] Oliveira J P, Panton B, Zeng Z, et al. Laser joining of NiTi to Ti6Al4V using a niobium interlayer[J]. Acta Materialia, 2016, 105: 9-15.

[14] Zhou X W, Huang Y D, Hao K, et al. Cracking in dissimilar laser welding of tantalum to molybdenum[J]. Optics & Laser Technology, 2018, 102: 54-59.

[15] Chen H C, Pinkerton A J, Li L. Fibre laser welding of dissimilar alloys of Ti6Al4V and Inconel 718 for aerospace applications[J]. The International Journal of Advanced Manufacturing Technology, 2011, 52(9/10/11/12): 977-987.

[16] Shojaei Zoeram A. Akbari Mousavi S A A. Effect of interlayer thickness on microstructure and mechanical properties of as welded Ti6Al4V/Cu/NiTi joints[J]. Materials Letters, 2014, 133: 5-8.

[17] Gao X L, Liu J, Zhang L J. Dissimilar metal welding of Ti6Al4V and Inconel 718 through pulsed laser welding-induced eutectic reaction technology[J]. The International Journal of Advanced Manufacturing Technology, 2018, 96(1/2/3/4): 1061-1071.

[18] Li S M, Xiao H, Liu K Y, et al. Melt-pool motion, temperature variation and dendritic morphology of Inconel 718 during pulsed- and continuous-wave laser additive manufacturing: a comparative study[J]. Materials & Design, 2017, 119: 351-360.

[19] Maharjan N, Zhou W, Zhou Y, et al. Comparative study of laser surface hardening of 50CrMo4 steel using continuous-wave laser and pulsed lasers with ms, ns, ps and fs pulse duration[J]. Surface and Coatings Technology, 2019, 366: 311-320.

[20] Saravanan S, Sivagurumanikandan N, Raghukandan K. Effect of heat input on microstructure and mechanical properties of Nd∶YAG laser welded super duplex stainless steel-numerical and experimental approach[J]. Optik, 2019, 185: 447-455.

李伦坤, 高晓龙, 刘晶, 王小强. 热输入对Ti6Al4V/Inconel 718激光诱导钎焊接头组织和力学性能的影响[J]. 中国激光, 2020, 47(5): 0502002. Lunkun Li, Xiaolong Gao, Jing Liu, Xiaoqiang Wang. Effects of Heat Input on Microstructure and Mechanical Properties of Ti6Al4V/Inconel 718 Laser-Induced Brazing Joint[J]. Chinese Journal of Lasers, 2020, 47(5): 0502002.