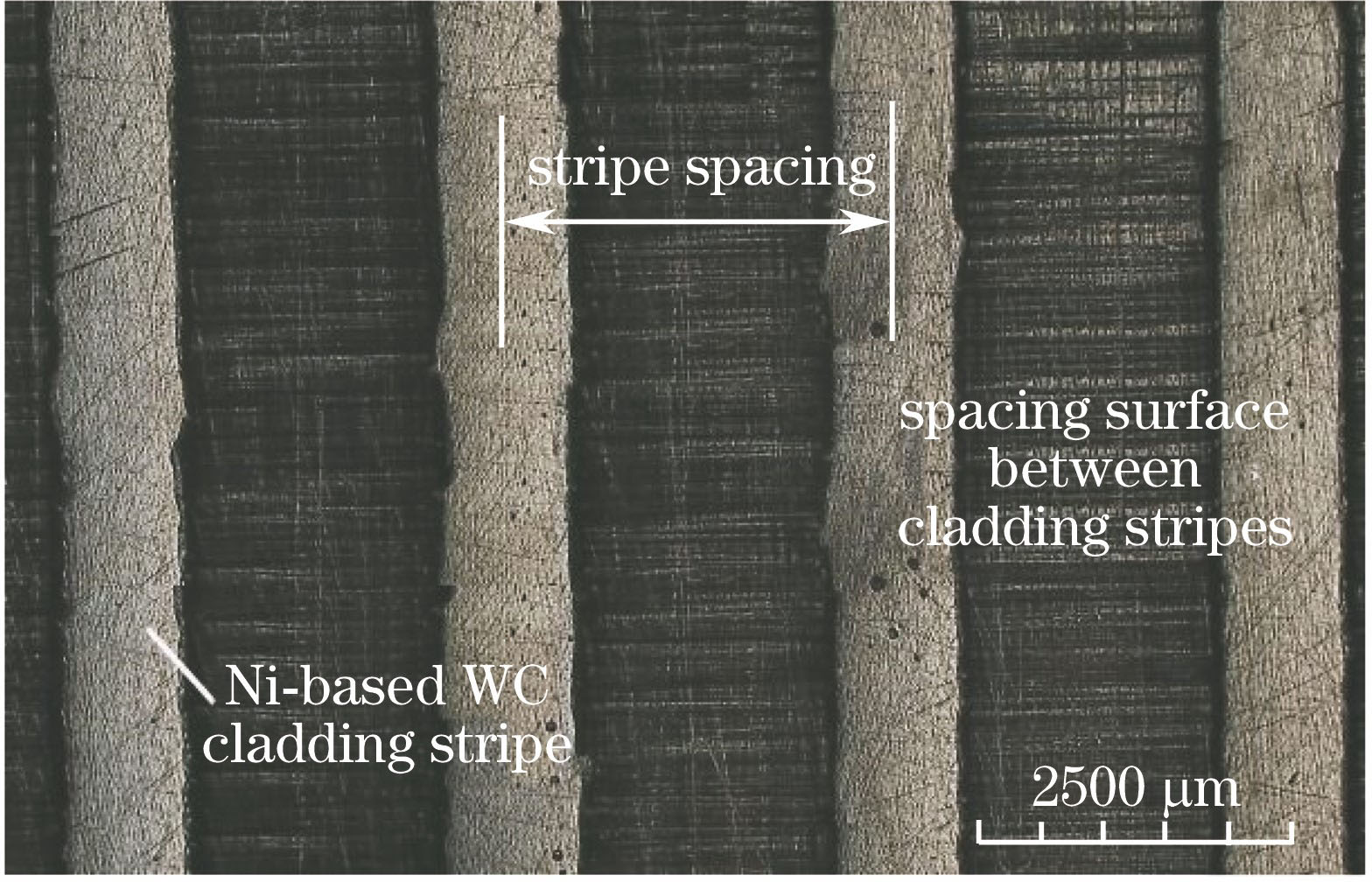

高速钢材料表面激光熔覆Ni基WC条纹的减摩机理  下载: 849次

下载: 849次

王燕琳, 何源, 洪鑫, 陈斌, 于爱兵. 高速钢材料表面激光熔覆Ni基WC条纹的减摩机理[J]. 激光与光电子学进展, 2018, 55(2): 021403.

Yanlin Wang, Yuan He, Xing Hong, Bin Chen, Aibing Yu. Friction Reducing Mechanism of High Speed Steel Surface with Ni-Based WC Stripes by Laser Cladding[J]. Laser & Optoelectronics Progress, 2018, 55(2): 021403.

[1] 昝少平, 焦俊科, 张文武. 316L不锈钢粉末激光熔覆工艺研究[J]. 激光与光电子学进展, 2016, 53(6): 061406.

[2] 苏永生, 李亮, 何宁, 等. 激光加工硬质合金刀具表面微织构的试验研究[J]. 中国激光, 2014, 41(6): 0603002.

[4] 李福泉, 冯鑫友, 陈彦宾. WC含量对WC/Ni60A激光熔覆层微观组织的影响[J]. 中国激光, 2016, 43(4): 0403009.

[5] 段晓溪, 高士友, 顾勇飞, 等. 激光熔覆316L+SiC的强化机制和摩擦磨损性能研究[J]. 中国激光, 2016, 43(1): 0103004.

[8] 朱顺敏, 苏美凤, 廖鹏飞. Q345钢激光熔覆镍基WC合金的组织与耐磨性能[J]. 材料保护, 2014, 47(8): 68-70.

Zhu S M, Su M F, Liao P F. Microstructure and wear resistance of laser cladding nickel-tungsten carbide coating on Q345 steel surface[J]. Materials Protection, 2014, 47(8): 68-70.

[9] 董刚, 郁伟, 陈智君, 等. 高WC含量Ni基合金激光熔覆及齿形零件的组合制造研究[J]. 应用激光, 2015, 35(2): 176-181.

[13] 谢高阳, 俞练民, 刘本耀, 等. 无机化学丛书第九卷[M]. 北京: 科学出版社, 2011: 270- 271.

[14] 温诗铸, 黄平. 摩擦学原理(第4版)[M]. 北京: 清华大学出版社, 2012.

Wen SZ, HuangP. Principles of tribology (4th edition)[M]. Beijing: Tsinghua University Press, 2012.

[15] 刘其斌, 朱维东, 邹龙江, 等. 宽带激光熔覆WCP/Ni基合金梯度复合涂层组织与摩擦磨损特性[J]. 复合材料学报, 2002, 19(6): 52-56.

Liu Q B, Zhu W D, Zou L J, et al. Microstructure and character of friction and wear of WCP/Ni based alloy gradient composite coating by wide-band laser cladding[J]. Acta Materiae Compositae Sinica, 2002, 19(6): 52-56.

王燕琳, 何源, 洪鑫, 陈斌, 于爱兵. 高速钢材料表面激光熔覆Ni基WC条纹的减摩机理[J]. 激光与光电子学进展, 2018, 55(2): 021403. Yanlin Wang, Yuan He, Xing Hong, Bin Chen, Aibing Yu. Friction Reducing Mechanism of High Speed Steel Surface with Ni-Based WC Stripes by Laser Cladding[J]. Laser & Optoelectronics Progress, 2018, 55(2): 021403.