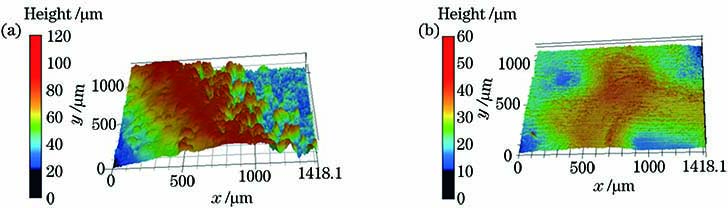

激光表面强化316L不锈钢的组织与性能研究  下载: 1067次

下载: 1067次

李鸿鹏, 盛金马, 黎彬, 常江, 张玉娇. 激光表面强化316L不锈钢的组织与性能研究[J]. 激光与光电子学进展, 2020, 57(19): 191601.

Hongpeng Li, Jinma Sheng, Bin Li, Jiang Chang, Yujiao Zhang. Microstructures and Properties of Laser Surface-Reinforced 316L Stainless Steel[J]. Laser & Optoelectronics Progress, 2020, 57(19): 191601.

[3] Ganesh P, Giri R, Kaul R, et al. Studies on pitting corrosion and sensitization in laser rapid manufactured specimens of type 316L stainless steel[J]. Materials & Design, 2012, 39: 509-521.

[4] Trelewicz J R, Halada G P, Donaldson O K, et al. Microstructure and corrosion resistance of laser additively manufactured 316L stainless steel[J]. JOM, 2016, 68(3): 850-859.

[5] 董齐, 黎宇航, 关红, 等. 基于纳米压痕和有限元模拟的激光熔覆316L不锈钢弹塑性能研究[J]. 塑性工程学报, 2017, 24(2): 128-133.

Dong Q, Li Y H, Guan H, et al. Nano-indentation and finite element simulation study on the elastic-plastic properties of 316L stainless steel by laser cladding[J]. Journal of Plasticity Engineering, 2017, 24(2): 128-133.

[6] 丁祥彬, 孙华, 俞国军, 等. Hastelloy N合金和316L不锈钢在LiF-NaF-KF熔盐中的腐蚀行为研究[J]. 中国腐蚀与防护学报, 2015, 35(6): 543-548.

Ding X B, Sun H, Yu G J, et al. Corrosion behavior of Hastelloy N and 316L stainless steel in molten LiF-NaF-KF[J]. Journal of Chinese Society for Corrosion and Protection, 2015, 35(6): 543-548.

[7] 郭鑫. 温轧和冷轧态含铝高强304与316L不锈钢微观组织和拉伸性能及其强韧化机制[D]. 兰州: 兰州理工大学, 2019: 18- 20.

GuoX. Microstructure, tensile properties and toughening mechanism of warm and cold rolling 304 and 316L stainless steels with aluminum[D]. Lanzhou: Lanzhou University of Technology, 2019: 18- 20.

[8] Colaço R, Pina C, Vilar R. Influence of the processing conditions on the abrasive wear behaviour of a laser surface melted tool steel[J]. Scripta Materialia, 1999, 41(7): 715-721.

[9] 张海潮. 激光重熔调质40Cr钢疲劳裂纹扩展行为及磨损性能[D]. 长春: 吉林大学, 2019: 30- 35.

Zhang HC. Fatigue crack propagation behavior and wear performance of laser remelted 40Cr steel[D]. Changchun: Jilin University, 2019: 30- 35.

[10] Tran V N, Yang S, Phung T A. Microstructure and properties of Cu/TiB2 wear resistance composite coating on H13 steel prepared by in situ laser cladding[J]. Optics & Laser Technology, 2018, 108: 480-486.

[11] Lin X, Cao Y Q, Wang Z T, et al. Regular eutectic and anomalous eutectic growth behavior in laser remelting of Ni-30wt%Sn alloys[J]. Acta Materialia, 2017, 126: 210-220.

[12] Zhang T, Fan Q, Ma X L, et al. Effect of laser remelting on microstructural evolution and mechanical properties of Ti-35Nb-2Ta-3Zr alloy[J]. Materials Letters, 2019, 253: 310-313.

[13] Zhou S F, Xu Y B, Liao B Q, et al. Effect of laser remelting on microstructure and properties of WC reinforced Fe-based amorphous composite coatings by laser cladding[J]. Optics & Laser Technology, 2018, 103: 8-16.

[14] Li Y H, Arthanari S, Guan Y C. Influence of laser surface melting on the properties of MB26 and AZ80 magnesium alloys[J]. Surface and Coatings Technology, 2019, 378: 124964.

[15] Zhang X Y, Zou Y, Zeng X L. Effect of laser surface remelting on the corrosion resistance of 316L orthodontic brackets[J]. International Journal of Electrochemical Science, 2016, 11: 2877-2886.

[16] Chikarakara E, Naher S, Brabazon D. Spinodal decomposition in AISI 316L stainless steel via high-speed laser remelting[J]. Applied Surface Science, 2014, 302: 318-321.

[17] ZbigniewB, BonekM, Dobrzański LA, et al., 2010, 654/655/656: 2511- 2514.

[18] Saeidi K, Gao X, Lofaj F, et al. Transformation of austenite to duplex austenite-ferrite assembly in annealed stainless steel 316L consolidated by laser melting[J]. Journal of Alloys and Compounds, 2015, 633: 463-469.

[19] Duan X X, Gao S Y, Dong Q, et al. Reinforcement mechanism and wear resistance of Al2O3/Fe-Cr-Mo steel composite coating produced by laser cladding[J]. Surface and Coatings Technology, 2016, 291: 230-238.

[20] 林鑫, 杨海欧, 陈静, 等. 激光快速成形过程中316L不锈钢显微组织的演变[J]. 金属学报, 2006, 42(4): 361-368.

Lin X, Yang H O, Chen J, et al. Microstructure evolution of 316L stainless steel during laser rapid forming[J]. Acta Metallurgica Sinica, 2006, 42(4): 361-368.

[21] Ganesh P, Kaul R, Sasikala G, et al. Fatigue crack propagation and fracture toughness of laser rapid manufactured structures of AISI 316L stainless steel[J]. Metallography, Microstructure, and Analysis, 2014, 3(1): 36-45.

李鸿鹏, 盛金马, 黎彬, 常江, 张玉娇. 激光表面强化316L不锈钢的组织与性能研究[J]. 激光与光电子学进展, 2020, 57(19): 191601. Hongpeng Li, Jinma Sheng, Bin Li, Jiang Chang, Yujiao Zhang. Microstructures and Properties of Laser Surface-Reinforced 316L Stainless Steel[J]. Laser & Optoelectronics Progress, 2020, 57(19): 191601.