Influence of surface roughness on surface plasmon resonance phenomenon of gold film  Download: 1030次

Download: 1030次

The surface plasmon resonance (SPR) phenomenon is a coupled electromagnetic field-charge density oscillation that occurs on the boundary between a dielectric and a metal[1,2]. For its high precision and sensitivity to the optical properties of dielectrics above metal films (e.g., gold, silver), SPR-based sensing devices have been successfully exploited in recent years[3,4]. The properties of the SPR in theory mainly depend on the characteristics of the thin film. At present, the dependence of the SPR on film thickness has been investigated widely.

However, the effects of the surface roughness of gold thin films on the properties of SPR have barely been studied[5]. In fact, there are discrepancies between most reported experimental measurements and the theoretical calculations of SPR even for films with a specific thickness. This inconsistency may result from researchers’ ignorance of the influence of surface roughness on theoretical SPR, as discussed in Ref. [6], in which a new dispersion law of metal thin films was exploited. Therefore, it is necessary to experimentally study the effects of surface roughness on the SPR properties of metal thin films.

In this work, we prepared gold films with a specific thickness under the same deposition conditions. By annealing at different temperatures, we obtained film samples with different surface morphologies. Then, the effects of the surface roughness of samples on the properties of SPR curves were examined.

Instead of depositing them on prisms, the gold films were made on K9 cover glass substrates using sputtering deposition, which makes it is more convenient to anneal the gold films at different temperatures. The cover glasses, which had a diameter of 22 mm, were cleaned in order to deposit the target. The deposit of the gold films was carried out using a commercial sputtering system with a DC sputtering power of 23 W at a rate of 2 nm/min for 22 min. Then, the thickness of these films was examined by x ray diffraction (PANalytical–Empyrean).

To obtain samples with different surface roughness, these gold films were annealed in a muffle furnace at four different temperatures (100°C, 200°C, 300°C, and 400°C) for 15 min. The surface roughness of the samples was measured using an atomic force microscope (AFM, Bruker-V Multimode) in contact mode, and characterized with root-mean-square roughness (RMS-roughness). We found that the surface roughness of the sample without annealing was almost the same as that annealed at 100°C. So in this work, we selected four samples annealed at 100°C, 200°C, 300°C, and 400°C (corresponding to samples 1, 2, 3, and 4, respectively) for later measurements.

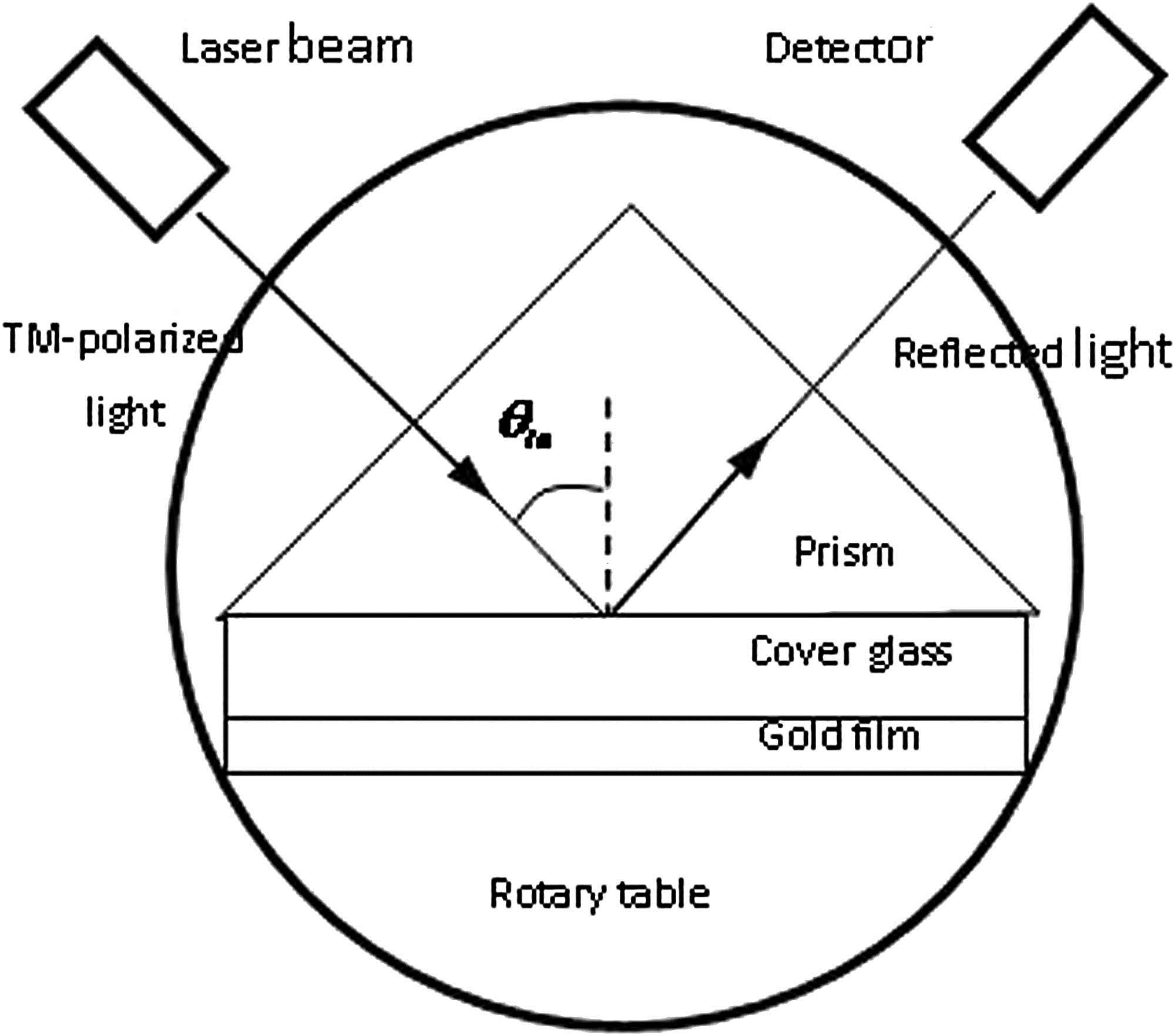

In order to examine the influence of the surface roughness on the SPR of gold films, we use the angle modulation in the SPR measurement depicted in Fig.

As shown in Fig.

The surface morphologies of the gold films scanned over

By the angle-modulating method, we examine the influence of the surface roughness of the gold films on the SPR phenomenon. The SPR curves of gold film samples with different surface roughness are shown in Fig.

Table 1. Results of Surface RMS-Roughness and SPR of Samples

|

From the results in Table

Here,

In the Ref. [6], an improved dispersion law of metal thin films (FS-DL model) was presented, and the permittivities of gold film with different surface roughness characterized by specularity were calculated. By employing the FS-DL model, the dependence of the specularity on the SPR was discussed. The results show that the resonance angle decreases by increasing the specularity from 0 to 1, which corresponds to the surface’s change from rough to smooth. In the present work, our experimental measurements prove the calculations in Ref. [6], i.e., the resonance angle will decrease when the surface of the gold film becomes smooth.

We investigate the effects of surface roughness on the SPR of gold films. The results show that the resonance angle of the SPR is sensitive to the surface roughness of the gold film. Specifically, the resonance angle gradually decreases with the reducing RMS-roughness, and the change rate of the resonance angle with RMS-roughness is about 0.485°/nm. These results are accord with the reported theoretical calculations. Therefore, the influence of the surface roughness of films on the SPR should be taken into account in the SPR technique.

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

Zhitao Yang, Changjian Liu, Yachen Gao, Jiyu Wang, Wenlong Yang. Influence of surface roughness on surface plasmon resonance phenomenon of gold film[J]. Chinese Optics Letters, 2016, 14(4): 042401.