Advanced fuel layering in line-moving, high-gain direct-drive cryogenic targets  Download: 703次

Download: 703次

Lebedev Physical Institute, Russian Academy of Sciences, Moscow 119991, Russia

Figures & Tables

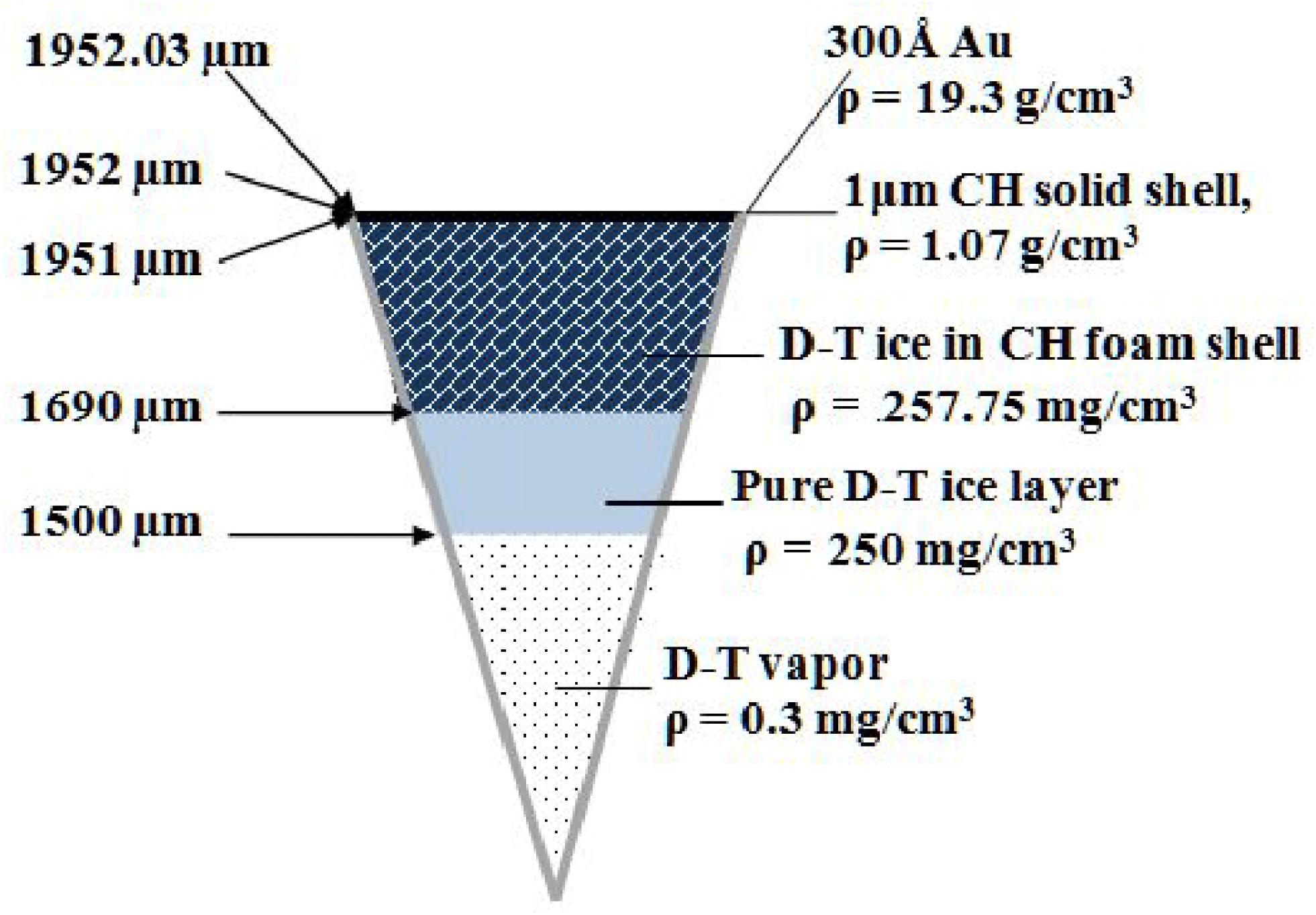

Fig. 1. A high-gain direct-drive target design proposed for a 1.3 MJ KrF laser[7].

下载图片 查看原文

Fig. 2. The phase state of $\text{D}_{2}$ fuel in the BODNER-Target upon cooling down. (a) PVT-diagram ($T_{\text{S}}$ is the temperature of fuel separation into the liquid and vapor phases). (b) Fuel state in the shell just before the FST layering versus the initial target temperature $T_{\text{in}}$: (1) gaseous fuel ($T_{\text{in}}>T_{\text{CP}}=38.34$ K), (2) compressed liquid ($36.5~\text{K}\sim T_{\text{S}}, $12.5~\text{atm}), (3) liquid $+$ vapor ($18.73~\text{K}=T_{\text{TP}}, $P<12.5$ atm).

下载图片 查看原文

Fig. 3. The FST layering method provides rapid symmetrization and freezing of solid ultrafine fuel layers. (a) Schematic of the FST layering module. (b) Target before layering (‘liquid $+$ vapor’ fuel state). (c) Target after FST layering (uniform solid layer). (d) Single-spiral LC (1) in the working assembly. (e) Single-spiral LC (1) shown with magnification. (f) Double-spiral LC.

下载图片 查看原文

Fig. 4. The gas pressure in the shell versus the fuel density near the critical point for (a) $\text{D}_{2}$ and (b) D–T.

下载图片 查看原文

Fig. 5. Depressurization temperature in the case of the BODNER-Target for $\text{D}_{2}$, $\text{T}_{2}$ and D–T.

下载图片 查看原文

Fig. 6. Dynamical layer symmetrization during FST layering: (a) schematic of the target rolling along the LC; (b) $T_{\text{in}}=21$ K and (c) $T_{\text{in}}=15$ K show the influence of $T_{\text{in}}$ on the layer uniformity. Both targets have the same parameters. But in case (c) during target rolling the liquid $\text{H}_{2}$ begins to spread onto the inner shell surface, and as $T_{\text{in}}=15$ K is close to $T_{\text{TP}}=13.96$ K for $\text{H}_{2}$, then quick freezing has begun before the achievement of layer uniformity.

下载图片 查看原文

Fig. 7. The relative radius of a vapor bubble ($\unicode[STIX]{x1D6FC}$) under the BODNER-Target cooling (filled with $\text{D}_{2}$ up to 1100 atm at room temperature); $\unicode[STIX]{x0394}T_{\text{max}}$ and $\unicode[STIX]{x0394}T_{\text{work}}$ are the maximum and working temperature ranges for uniform layering ($T_{\text{S}}=36.5$ K, $T_{\text{d}}=27.5$ K).

下载图片 查看原文

Fig. 8. Cooling time of several thin metal overcoats for different target designs ($\varnothing$ – diameter, $W$ – cryogenic layer thickness).

下载图片 查看原文

Fig. 9. $\text{H}_{2}$–liquid–vapor interface behavior (meniscus) for $\unicode[STIX]{x1D703}\leqslant 1$ (1, vapor; 2, liquid). In (a), with $\unicode[STIX]{x1D703}=0.69$ (polystyrene shell, $\varnothing =940~\unicode[STIX]{x03BC}\text{m}$, fill pressure $P_{\text{f}}=305$ atm at 300 K), the meniscus varies typically. In (b), with $\unicode[STIX]{x1D703}=0.91$ ($\varnothing =949~\unicode[STIX]{x03BC}\text{m}$, $P_{\text{f}}=445$ atm), near the critical density for $\text{H}_{2}$, the meniscus varies greatly, from strongly concave downwards at $T=14$ K to almost flat at $T=33$ K (a flat meniscus indicates the same material properties on both sides of the meniscus when approaching the critical point).

下载图片 查看原文

Fig. 10. $\text{H}_{2}$–liquid–vapor interface behavior for $\unicode[STIX]{x1D703}>1$ (1, vapor; 2, liquid). (a) $\unicode[STIX]{x1D703}=1.32$ (polystyrene shell, $\varnothing =980~\unicode[STIX]{x03BC}\text{m}$, $P_{\text{f}}=765$ atm); (b) $\unicode[STIX]{x1D703}=1.6$ (superdurable glass shell, $\varnothing =250~\unicode[STIX]{x03BC}\text{m}$, $P_{\text{f}}=1100$ atm).

下载图片 查看原文

Fig. 11. A variety of IFE target designs can be balanced by a corresponding choice of the LC design.

下载图片 查看原文

Fig. 12. A standard case of LC winding. The difficulty in designing TrCs arises from the need to have smooth target travel along the LC to avoid sudden changes in the acceleration.

下载图片 查看原文

Table1. Parameters of the BODNER-Target for both $\text{D}_{2}$ and D–T fuel.

| Parameters | values | D–T values |

|---|

| Target mass | ${\sim}$3.5 mg | ${\sim}$4.4 mg | | Shell mass | $160.5~\unicode[STIX]{x03BC}\text{g}$ | $160.5~\unicode[STIX]{x03BC}\text{g}$ | | – compact polymer | $51.2~\unicode[STIX]{x03BC}\text{g}$ | $51.2~\unicode[STIX]{x03BC}\text{g}$ | | – porous polymer | $109.3~\unicode[STIX]{x03BC}\text{g}$ | $109.3~\unicode[STIX]{x03BC}\text{g}$ | | Fuel mass | 3.3 mg | 4.2 mg | | – in-porous fuel | 2.1 mg | 2.7 mg | | – pure solid fuel | 1.2 mg | 1.5 mg | | – vapor fuel | $6.3~\unicode[STIX]{x03BC}\text{g}$ | $4.24~\unicode[STIX]{x03BC}\text{g}$ | | Fill density, $\unicode[STIX]{x1D70C}_{\text{f}}$ | ${\sim}107~\text{mg}/\text{cm}^{3}$ | ${\sim}136~\text{mg}/\text{cm}^{3}$ | | Fill pressure, $P_{\text{f}}$ | ${\sim}$1100 atm | ${\sim}$1100 atm |

|

查看原文

Table2. Critical parameters (density, pressure, temperature) for the hydrogen isotopes[13].

| Hydrogen isotopes | | | | D–T |

|---|

| $\unicode[STIX]{x1D70C}_{\text{CP}}$, $\text{mg}/\text{cm}^{3}$ | 30.10 | 69.80 | 108.97 | 87.10 | | $P_{\text{CP}}$, atm | 12.98 | 16.43 | 18.26 | 17.50 | | $T_{\text{CP}}$, K | 33.19 | 38.34 | 40.44 | 39.42 |

|

查看原文

Table3. Pressure and temperature for the hydrogen isotopes at the boiling and triple points[13].

| Hydrogen isotopes | | | | D–T |

|---|

| $T_{\text{BP}}$, K | 20.39 | 23.66 | 25.04 | 24.38 | | $P_{\text{BP}}$, atm | 1.0 | 1.0 | 1.0 | 1.0 | | $T_{\text{TP}}$, K | 13.96 | 18.73 | 20.62 | 19.79 | | $P_{\text{TP}}$, atm | 0.07 | 0.17 | 0.21 | 0.19 |

|

查看原文

Table4. Required tensile strength near the critical point temperature.

| Target | Pressure | Tensile strength |

|---|

| temperature | $\text{D}_{2}$ | D–T | $\text{D}_{2}$ | D–T |

|---|

| 45.00 K | 47.68 atm | 44.94 atm | ${\sim}$4654 MPa | ${\sim}$4368 MPa | | 40.00 K | 28.96 atm | 25.89 atm | ${\sim}$2826 MPa | ${\sim}$2527 MPa | | 38.34 K ($\text{D}_{2}$) | 22.74 atm | – | ${\sim}$2219 MPa | – | | 39.42 K (D–T) | – | 23.99 atm | – | ${\sim}$2341 MPa |

|

查看原文

Table5. The BODNER-Target layering time.

| $\text{D}_{2}$ fuel |

|---|

|

|---|

| Layering time | $\unicode[STIX]{x1D70F}_{\text{Liquid}}$ | $\unicode[STIX]{x1D70F}_{\text{Solid}}$ | $\unicode[STIX]{x1D70F}_{\text{Cool}}$ | $\unicode[STIX]{x1D70F}_{\text{Form}}$ ($\unicode[STIX]{x1D712}_{\text{g}}$) | $\unicode[STIX]{x1D70F}_{\text{Form}}$ ($\unicode[STIX]{x1D712}_{\text{eff}}$) |

|---|

| Stage 1 | | | | | | | (a) $T_{\text{in}}=T_{\text{S}}\sim 35.0$ K | 17.48 s | – | – | (a) 22.45 s | less than | | (b) $T_{\text{in}}=T_{\text{d}}=27.5$ K | 7.08 s | | | (b) 12.05 s | 0.5 s | | Stage 2 | | | | | | | $T_{\text{TP}}=18.71$ K | – | 4.97 s | – | | | | | D–T fuel | | | Layering time | $\unicode[STIX]{x1D70F}_{\text{Liquid}}$ | $\unicode[STIX]{x1D70F}_{\text{Solid}}$ | $\unicode[STIX]{x1D70F}_{\text{Cool}}$ | $\unicode[STIX]{x1D70F}_{\text{Form}}$ ($\unicode[STIX]{x1D712}_{\text{g}}$) | $\unicode[STIX]{x1D70F}_{\text{Form}}$ ($\unicode[STIX]{x1D712}_{\text{eff}}$) | | | Stage 1 | | | | | | | (a) $T_{\text{in}}=T_{\text{S}}\sim 37.5$ K | 22.14 s | – | – | (a) 28.52 s | less than | | (b) $T_{\text{in}}=T_{\text{d}}=28.0$ K | 7.87 s | | | (b) 14.25 s | 0.5 s | | Stage 2 | | | | | | | $T_{\text{TP}}=19.79$ K | – | 5.23 s | – | | | | Stage 3 | | | | | | | $T_{\text{Cool}}=18.3$ K | – | – | 1.15 s | | |

|

查看原文

Table6. Double-spiral LC (mockup testing results).

| Specifications | Values | Specifications | Values |

|---|

| Spiral number | $n=2$ | Total number of turns | $\unicode[STIX]{x1D714}=44$ | | Spiral diameter | $\text{OD}=42$ mm | Tube diameter | $\text{ID}=4.4$ mm, $\text{OD}=6$ mm | | Spiral height | $H=450$ mm | Length of each spiral | $L_{n}=2261$ mm | | Spiral angle | $\unicode[STIX]{x1D6FC}=11.5^{\circ }$ | Residence time (PS shell)a | $\unicode[STIX]{x1D70F}_{\text{Res}}=23.5$ s ($\unicode[STIX]{x1D70F}_{\text{Form}}=22.45$ s for $\text{D}_{2}$) |

|

查看原文

Table7. Three-fold-spiral LC (mockup testing results).

| Specifications #1 | Values | Specifications #1 | Values |

|---|

| Spiral number | $n=3$ | Total number of turns | $\unicode[STIX]{x1D714}=77$ | | Spiral diameter | $\text{OD}=42$ mm | Tube diameter | $\text{ID}=4.4$ mm, $\text{OD}=6$ mm | | Spiral height | $H=880$ mm | Length of each spiral | $L_{n}=3066$ mm | | Spiral angle | $\unicode[STIX]{x1D6FC}=16.7^{\circ }$ | Residence time (CH shell)a | $\unicode[STIX]{x1D70F}_{\text{Res}}>35$ s ($\unicode[STIX]{x1D70F}_{\text{Form}}=28.52$ s for D–T) |

|

查看原文

Table8. Combined three-fold-spiral LC.

| Specifications #2 | Values |

|---|

| Radius of Spiral 4 | 21 mm | | Length of Spiral 4 | 2.070 m | | Total length of Spiral 3 $+$ Spiral 4 | 5.136 m | | Angle of Spiral 4 | $\unicode[STIX]{x1D6FC}=3^{\circ }$ | | Height of Spiral 4 | 10.8 cm |

|

查看原文

Table9. Existence time of the liquid phase at different temperatures $T_{\text{in}}$.

| Experiment | Calculation |

|---|

| # | | LC | | | |

|---|

| 1 | 21 K | Cylinder | 8 s | 7.22 s | 2.97 s | | 2 | 15 K | Cylinder | 8 s | 5.13 s | 0.97 s |

|

查看原文

I. V. Aleksandrova, E. R. Koresheva. Advanced fuel layering in line-moving, high-gain direct-drive cryogenic targets[J]. High Power Laser Science and Engineering, 2019, 7(3): 03000e38.

Download: 703次

Download: 703次