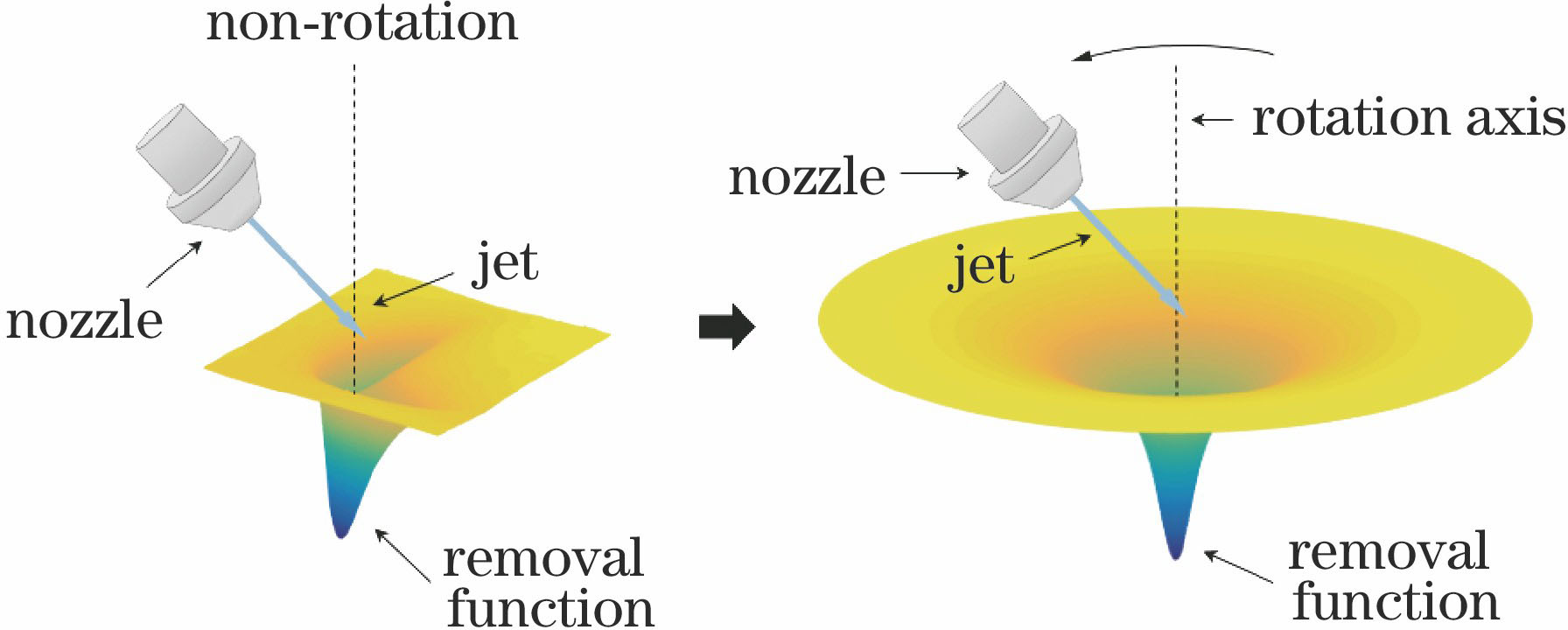

射流抛光中生成高斯型去除函数的数学建模方法  下载: 856次

下载: 856次

王中昱, 张连新, 孙鹏飞, 李建, 尹承真. 射流抛光中生成高斯型去除函数的数学建模方法[J]. 光学学报, 2018, 38(10): 1022002.

Zhongyu Wang, Lianxin Zhang, Pengfei Sun, Jian Li, Chengzhen Yin. Mathematical Modeling Method for Generation of Gaussian-Type Removal Function in Fluid Jet Polishing[J]. Acta Optica Sinica, 2018, 38(10): 1022002.

[1] 席建普, 李彬, 任东旭, 等. 大口径非球面元件磨削轮廓测量技术研究进展[J]. 激光与光电子学进展, 2018, 55(3): 030008.

[2] Yuan J L, Wu Z, Lü B H, et al. Review on ultra-precision polishing technology of aspheric surface[J]. Journal of Mechanical Engineering, 2012, 48(23): 167.

[3] 方慧. 液体喷射抛光技术[D]. 苏州: 苏州大学, 2004.

FangH. Fluid jet polishing[D]. Suzhou: Soochow University, 2004.

[4] 吕亮, 马平, 朱衡, 等. 水射流抛光去除函数对面形误差修正的影响[J]. 中国激光, 2016, 43(4): 0416003.

[11] Booij SM. Fluid jet polishing-possibilities and limitations of a new fabrication technique[D]. Delft: Delft University, 2003.

[12] 李兆泽. 磨料水射流抛光技术研究[D]. 长沙:国防科技大学, 2011: 43- 46.

Li ZZ. Study on abrasive jet polishing technology[D]. Changsha: National University of Defense Technology, 2011: 43- 46.

[13] 李建, 张连新, 孙鹏飞, 等. 射流抛光高斯型去除函数的快速生成实验方法[J]. 光学学报, 2018, 38(7): 0722002.

[14] 施春燕, 袁家虎, 伍凡, 等. 射流抛光误差分析与材料去除稳定性研究[J]. 光学学报, 2011, 31(1): 0112012.

[15] 施春燕, 袁家虎, 伍凡, 等. 喷射距离对射流抛光去除函数的影响[J]. 红外与激光工程, 2011, 40(4): 685-689.

[16] 王佳, 范斌, 万勇建, 等. 一种评价CCOS抛光工艺误差抑制能力的方法[J]. 光子学报, 2014, 43(7): 0722002.

王中昱, 张连新, 孙鹏飞, 李建, 尹承真. 射流抛光中生成高斯型去除函数的数学建模方法[J]. 光学学报, 2018, 38(10): 1022002. Zhongyu Wang, Lianxin Zhang, Pengfei Sun, Jian Li, Chengzhen Yin. Mathematical Modeling Method for Generation of Gaussian-Type Removal Function in Fluid Jet Polishing[J]. Acta Optica Sinica, 2018, 38(10): 1022002.