光纤激光器在金属增材制造中的应用进展及展望  下载: 1932次特邀综述

下载: 1932次特邀综述

杨永强, 吴世彪, 张越, 朱勇强. 光纤激光器在金属增材制造中的应用进展及展望[J]. 中国激光, 2020, 47(5): 0500012.

Yongqiang Yang, Shibiao Wu, Yue Zhang, Yongqiang Zhu. Application Progress and Prospect of Fiber Laser in Metal Additive Manufacturing[J]. Chinese Journal of Lasers, 2020, 47(5): 0500012.

[1] Everton S K, Hirsch M, Stravroulakis P, et al. Review of in situ process monitoring and in situ metrology for metal additive manufacturing[J]. Materials & Design, 2016, 95: 431-445.

[2] Doubenskaia M, Domashenkov A, Smurov I, et al. Study of selective laser melting of intermetallic TiAl powder using integral analysis[J]. International Journal of Machine Tools and Manufacture, 2018, 129: 1-14.

[3] FosnessE, CarpenterB, TupperM, et al. Development of low shock deployment devices for aerospace applications using shape memory and elastic memory composites[C]∥AIAA Space 2003 Conference & Exposition, Long Beach, California. Reston, Virigina: AIAA, 2003: 6246.

[4] Shangguan H L, Kang J W, Deng C Y, et al. 3D-printed shell-truss sand mold for aluminum castings[J]. Journal of Materials Processing Technology, 2017, 250: 247-253.

[5] Upadhyay M, Sivarupan T, El Mansori M. 3D printing for rapid sand casting: a review[J]. Journal of Manufacturing Processes, 2017, 29: 211-220.

[6] 全国增材制造标准化技术委员会. 增材制造术语: GB/T 35351—2017[S]. 北京: 中国标准出版社, 2017.

National Technical Committee on Additive Manufacturing of Standardization Administration of China. Additive manufacturing—terminology: GB/T 35351—2017[S]. Beijing: China Standard Press, 2017.

[8] Do T, Kwon P, Shin C S. Process development toward full-density stainless steel parts with binder jetting printing[J]. International Journal of Machine Tools and Manufacture, 2017, 121: 50-60.

[9] Ziaee M, Crane N B. Binder jetting: a review of process, materials, and methods[J]. Additive Manufacturing, 2019, 28: 781-801.

[10] Zhang Y, Wu LM, Guo X Y, et al. Additive manufacturing of metallic materials: a review[J]. Journal of Materials Engineering and Performance, 2018, 27(1): 1-13.

[11] ShellabearM, NyrhiläO. DMLS-development history and state of the art[J/OL]. [2020-03-28].https:∥scholar.google.com/scholar?q=DMLS-Development+history+and+state+of+the+art&hl=en&as_sdt=0, 5.

[12] 王一礴, 李进延. 高功率掺镱光纤的现状及发展趋势[J]. 中国激光, 2017, 44(2): 0201009.

[13] Boddu MR, Landers RG, Liou FW. Control of laser cladding for rapid prototyping: a review[J]. [2020-03-28].http:∥edge.rit.edu/content/P10551/public/SFF/SFF%202001%20Proceedings/2001%20SFF%20Papers/52-Boddu,Control.pdf.

[14] Kaierle S, Barroi A, Noelke C, et al. Review on laser deposition welding: from micro to macro[J]. Physics Procedia, 2012, 39: 336-345.

[15] FominV, GapontsevV, ShcherbakovE, et al., June 30-July 4, 2014. Saint Petersburg, Russia. [S.l.]:IEEE, 20146886450.

[16] Wu W J, Chen Z L, Wang Z F, et al. Beam combining of fiber lasers by a 3×1 signal combiner at a power >13 kW[J]. Optical Fiber Technology, 2020, 54: 102109.

[18] Xie Z X, Shi C D, Sheng Q, et al. A single-frequency 1064-nm Yb 3+ -doped fiber laser tandem-pumped at 1018 nm[J]. Optics Communications, 2020, 461: 125262.

[19] Addanki S, Amiri I S, Yupapin P. Review of optical fibers-introduction and applications in fiber lasers[J]. Results in Physics, 2018, 10: 743-750.

[20] Lee H. Lim C H J, Low M J, et al. Lasers in additive manufacturing:a review[J]. International Journal of Precision Engineering and Manufacturing-Green Technology, 2017, 4(3): 307-322.

[21] 龚小弟, 王智, 于宁, 等. 用于选择性激光烧结的聚合物粉末材料研究进展[J]. 功能材料, 2019, 50(10): 10027-10039.

Gong X D, Wang Z, Yu N, et al. Research progress of polymer powder materials for SLS forming technology[J]. Journal of Functional Materials, 2019, 50(10): 10027-10039.

[22] 林峰. 电子束粉末床熔融技术研究进展与前瞻[J]. 新经济导刊, 2019( 1): 35- 39.

LinF. Research progress and prospect of electron beam powder bed fusion technology[J]. New Economy Leader, 2019( 1): 35- 39.

[23] 赵德陈, 林峰. 金属粉末床熔融工艺在线监测技术综述[J]. 中国机械工程, 2018, 29(17): 2100-2110, 2118.

Zhao D C, Lin F. A review of on-line monitoring techniques in metal powder bed fusion processes[J]. China Mechanical Engineering, 2018, 29(17): 2100-2110, 2118.

[24] Tolochko N K, Khlopkov Y V, Mozzharov S E, et al. Absorptance of powder materials suitable for laser sintering[J]. Rapid Prototyping Journal, 2000, 6(3): 155-161.

[25] Garban-Labaune C, Fabre E, Max C E, et al. Effect of laser wavelength and pulse duration on laser-light absorption and back reflection[J]. Physical Review Letters, 1982, 48(15): 1018.

[26] 王炜, 唐霞辉, 秦应雄, 等. 腔镜面型对射频板条CO2激光器输出模式的影响[J]. 中国激光, 2016, 43(4): 0402004.

[27] 杨永强, 陈杰, 宋长辉, 等. 金属零件激光选区熔化技术的现状及进展[J]. 激光与光电子学进展, 2018, 55(1): 011401.

[28] 白玉超, 杨永强, 王迪, 等. 锡青铜激光选区熔化工艺及其性能[J]. 稀有金属材料与工程, 2018, 47(3): 1007-1012.

Bai Y C, Yang Y Q, Wang D, et al. Selective laser melting of tin bronze alloy and its properties[J]. Rare Metal Materials and Engineering, 2018, 47(3): 1007-1012.

[29] Bai Y C, Wang D, Yang Y Q, et al. Effect of heat treatment on the microstructure and mechanical properties of maraging steel by selective laser melting[J]. Materials Science and Engineering: A, 2019, 760: 105-117.

[30] 宋长辉, 杨永强, 王赟达, 等. CoCrMo合金激光选区熔化成型工艺及其性能研究[J]. 中国激光, 2014, 41(6): 0603001.

[31] Sun J F, Yang Y Q, Wang D. Parametric optimization of selective laser melting for forming Ti6Al4V samples by Taguchi method[J]. Optics & Laser Technology, 2013, 49: 118-124.

[32] Liu J W, Song Y N, Chen C Y, et al. Effect of scanning speed on the microstructure and mechanical behavior of 316L stainless steel fabricated by selective laser melting[J]. Materials & Design, 2020, 186: 108355.

[33] Bi J, Lei Z L, Chen Y B, et al. Microstructure and mechanical properties of a novel Sc and Zr modified 7075 aluminum alloy prepared by selective laser melting[J]. Materials Science and Engineering: A, 2019, 768: 138478.

[34] Wei K, Yang Q D, Ling B, et al. Mechanical properties of Invar 36 alloy additively manufactured by selective laser melting[J]. Materials Science and Engineering: A, 2020, 772: 138799.

[35] Montero-Sistiaga M L, Godino-Martinez M, Boschmans K, et al. Microstructure evolution of 316L produced by HP-SLM (high power selective laser melting)[J]. Additive Manufacturing, 2018, 23: 402-410.

[36] Rafi H K, Karthik N V, Gong H J, et al. Microstructures and mechanical properties of Ti6Al4V parts fabricated by selective laser melting and electron beam melting[J]. Journal of Materials Engineering and Performance, 2013, 22(12): 3872-3883.

[37] Read N, Wang W, Essa K, et al. Selective laser melting of AlSi10Mg alloy: process optimisation and mechanical properties development[J]. Materials & Design (1980—2015), 2015, 65: 417-424.

[38] Simonelli M, Tse Y Y, Tuck C. Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti-6Al-4V[J]. Materials Science and Engineering: A, 2014, 616: 1-11.

[39] Bai Y C, Yang Y Q, Wang D, et al. Influence mechanism of parameters process and mechanical properties evolution mechanism of maraging steel 300 by selective laser melting[J]. Materials Science and Engineering: A, 2017, 703: 116-123.

[40] Liu Y, Yang Y Q, Mai S Z, et al. Investigation into spatter behavior during selective laser melting of AISI 316L stainless steel powder[J]. Materials & Design, 2015, 87: 797-806.

[41] Colopi M, Caprio L, Demir A G, et al. Selective laser melting of pure Cu with a 1 kW single mode fiber laser[J]. Procedia CIRP, 2018, 74: 59-63.

[42] Zhang M K, Yang Y Q, Wang D, et al. Effect of heat treatment on the microstructure and mechanical properties of Ti6Al4V gradient structures manufactured by selective laser melting[J]. Materials Science and Engineering: A, 2018, 736: 288-297.

[43] Chen J, Yang Y Q, Song C H, et al. Interfacial microstructure and mechanical properties of 316L /CuSn10 multi-material bimetallic structure fabricated by selective laser melting[J]. Materials Science and Engineering: A, 2019, 752: 75-85.

[44] Xiao Z F, Yang Y Q, Xiao R, et al. Evaluation of topology-optimized lattice structures manufactured via selective laser melting[J]. Materials & Design, 2018, 143: 27-37.

[45] Zhang M K, Yang Y Q, Wang D, et al. Microstructure and mechanical properties of CuSn/18Ni300 bimetallic porous structures manufactured by selective laser melting[J]. Materials & Design, 2019, 165: 107583.

[46] Thompson S M, Bian L K, Shamsaei N, et al. An overview of direct laser deposition for additive manufacturing: transport phenomena, modeling and diagnostics[J]. Additive Manufacturing, 2015, 8: 36-62.

[47] Singh D D, Arjula S, Reddy A R. Metal additive manufacturing by powder blown beam deposition process[J]. International Journal of Engineering and Advanced Technology, 2019, 9(2): 5291-5304.

[48] 宗贵升, 赵浩. 金属增材制造技术工艺及应用[J]. 粉末冶金工业, 2019, 29(5): 1-6.

Zong G S, Zhao H. Technology and application of metal 3D printing[J]. Powder Metallurgy Industry, 2019, 29(5): 1-6.

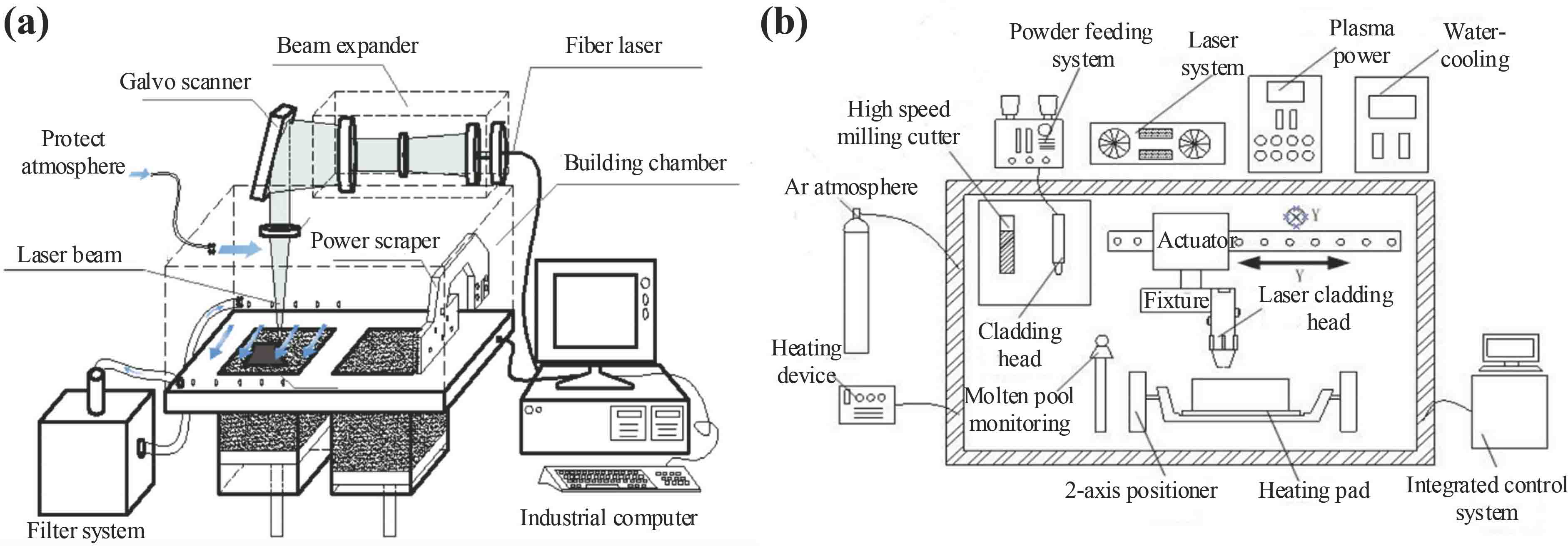

[49] 杨永强, 翁昌威, 周权, 等. 316L不锈钢等离子增材制造工艺与尺寸预测模型研究[J]. 机械工程学报, 2019, 55(15): 31-38.

Yang Y Q, Weng C W, Zhou Q, et al. Research on the process and prediction model for size of 316L stainless steel fabricated by plasma arc additive manufacturing[J]. Journal of Mechanical Engineering, 2019, 55(15): 31-38.

[50] 许可可, 陈克选, 仇文杰, 等. 等离子弧增材制造设备与其工艺研究[J]. 热加工工艺, 2017, 46(23): 221-224.

Xu K K, Chen K X, Qiu W J, et al. Study on equipment and process of plasma arc additive manufacturing[J]. Hot Working Technology, 2017, 46(23): 221-224.

[51] 陈哲源, 锁红波, 李晋炜. 电子束熔丝沉积快速制造成型技术与组织特征[J]. 航天制造技术, 2010( 1): 36- 39.

Chen ZY, Suo HB, Li JW. The forming character of electron beam freeform fabrication[J]. Aerospace Manufacturing Technology, 2010( 1): 36- 39.

[52] Kazanas P, Deherkar P, Almeida P, et al. Fabrication of geometrical features using wire and arc additive manufacture[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2012, 226(6): 1042-1051.

[53] MajumdarJD, MannaI. Introduction to laser assisted fabrication of materials[M] ∥Laser-Assisted Fabrication of Materials. Berlin, Heidelberg: Springer, 2012: 1- 67.

[54] 汤海波, 吴宇, 张述泉, 等. 高性能大型金属构件激光增材制造技术研究现状与发展趋势[J]. 精密成形工程, 2019, 11(4): 58-63.

Tang H B, Wu Y, Zhang S Q, et al. Research status and development trend of high performance large metallic components by laser additive manufacturing technique[J]. Journal of Netshape Forming Engineering, 2019, 11(4): 58-63.

[55] Keicher DM, Jellison JL, Schanwald LP, et al. Towards a reliable laser spray powder deposition system through process characterization[C]∥International Technical Conference of the Society for the Advancement of Material and Process Engineering (SAMPE). Washington, D.C.: [s.n.], 1995: 97201.

[56] Keicher DM, Romero JA, Atwood CL, et al. Laser engineered net shaping (LENS TM) for additive component processing [C]∥1996 Rapid Prototyping and Manufacturing, Dearborn, MI (United States). Washington, D.C.: [s.n.], 1996: 231692.

[57] Keicher DM, Romero JA, Atwood CL, et al. Free form fabrication using the laser engineered net shaping (LENS TM) process[R]. [S.l.]: Office of Scientific and Technical Information (OSTI), 1996: 425303.

[58] Carroll B E, Palmer T A, Beese A M. Anisotropic tensile behavior of Ti-6Al-4V components fabricated with directed energy deposition additive manufacturing[J]. Acta Materialia, 2015, 87: 309-320.

[59] Keist J S, Palmer T A. Role of geometry on properties of additively manufactured Ti-6Al-4V structures fabricated using laser based directed energy deposition[J]. Materials & Design, 2016, 106: 482-494.

[60] Åkerfeldt P, Antti M L, Pederson R. Influence of microstructure on mechanical properties of laser metal wire-deposited Ti-6Al-4V[J]. Materials Science and Engineering: A, 2016, 674: 428-437.

[61] Li Z, Chen J, Sui S, et al. The microstructure evolution and tensile properties of Inconel 718 fabricated by high-deposition-rate laser directed energy deposition[J]. Additive Manufacturing, 2020, 31: 100941.

[62] Angelastro A, Campanelli S L, Casalino G. Statistical analysis and optimization of direct metal laser deposition of 227-F colmonoy nickel alloy[J]. Optics & Laser Technology, 2017, 94: 138-145.

[63] Huang W B, Zhang Y M, Dai W B, et al. Mechanical properties of 304 austenite stainless steel manufactured by laser metal deposition[J]. Materials Science and Engineering: A, 2019, 758: 60-70.

[64] Arrizubieta J I, Lamikiz A, Cortina M, et al. Hardness, grainsize and porosity formation prediction on the laser metal deposition of AISI 304 stainless steel[J]. International Journal of Machine Tools and Manufacture, 2018, 135: 53-64.

[65] Kim D K, Woo W, Kim E Y, et al. Microstructure and mechanical characteristics of multi-layered materials composed of 316L stainless steel and ferritic steel produced by direct energy deposition[J]. Journal of Alloys and Compounds, 2019, 774: 896-907.

[66] Akbari M, Kovacevic R. An investigation on mechanical and microstructural properties of 316LSi parts fabricated by a robotized laser/wire direct metal deposition system[J]. Additive Manufacturing, 2018, 23: 487-497.

[67] Shiva S, Palani I A, Mishra S K, et al. Investigations on the influence of composition in the development of Ni-Ti shape memory alloy using laser based additive manufacturing[J]. Optics & Laser Technology, 2015, 69: 44-51.

[68] Xiang S, Luan H W, Wu J, et al. Microstructures and mechanical properties of CrMnFeCoNi high entropy alloys fabricated using laser metal deposition technique[J]. Journal of Alloys and Compounds, 2019, 773: 387-392.

[69] Su S, Lu Y Z. Laser directed energy deposition of Zr-based bulk metallic glass composite with tensile strength[J]. Materials Letters, 2019, 247: 79-81.

[70] Lv F, Shen L D, Liang H X, et al. Mechanical properties of AlSi10Mg alloy fabricated by laser melting deposition and improvements via heat treatment[J]. Optik, 2019, 179: 8-18.

[71] Li H, Chen B, Tan C W, et al. Microstructure evolution and mechanical properties of laser metal deposition of Invar 36 alloy[J]. Optics & Laser Technology, 2020, 125: 106037.

杨永强, 吴世彪, 张越, 朱勇强. 光纤激光器在金属增材制造中的应用进展及展望[J]. 中国激光, 2020, 47(5): 0500012. Yongqiang Yang, Shibiao Wu, Yue Zhang, Yongqiang Zhu. Application Progress and Prospect of Fiber Laser in Metal Additive Manufacturing[J]. Chinese Journal of Lasers, 2020, 47(5): 0500012.