光纤激光器在金属增材制造中的应用进展及展望  下载: 1933次特邀综述

下载: 1933次特邀综述

Application Progress and Prospect of Fiber Laser in Metal Additive Manufacturing

华南理工大学机械与汽车工程学院, 广东 广州 510641

图 & 表

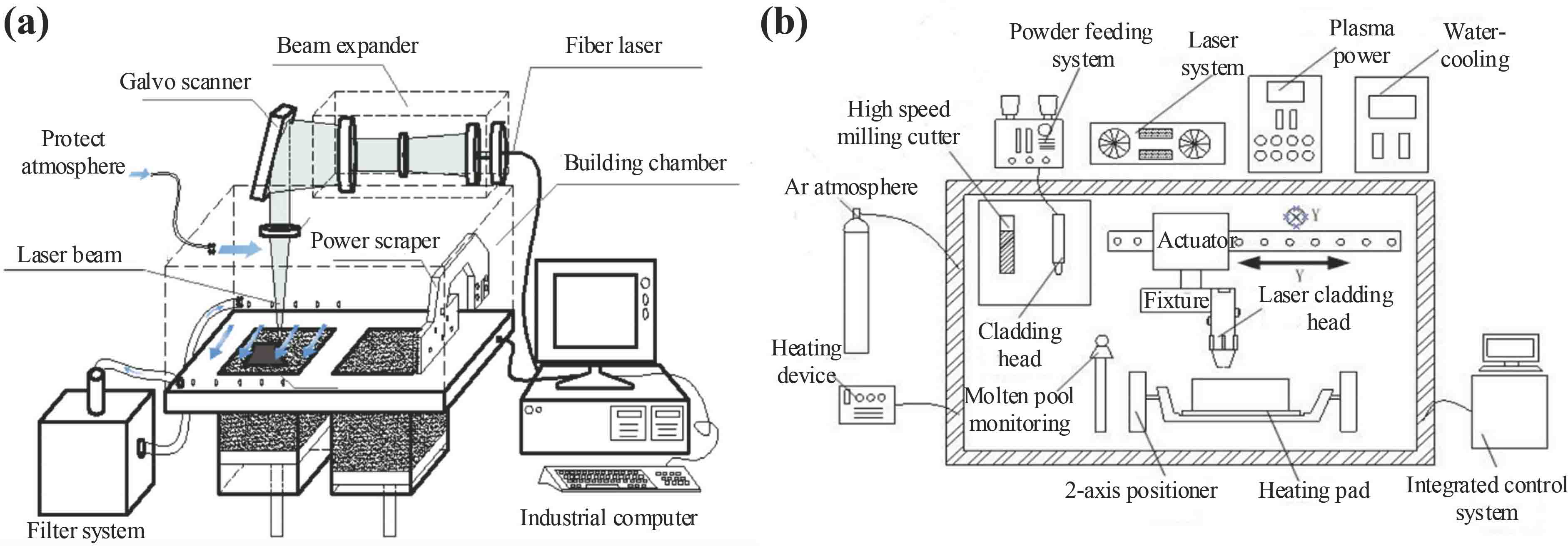

图 1. 激光金属增材制造典型系统原理图。(a)粉末床熔融增材制造系统;(b)定向能量沉积增减材复合制造系统

Fig. 1. Schematics of two typical laser additive manufacturing system for metal. (a) Powder bed fusion additive manufacturing system; (b) directed energy deposition additive and subtractive composite manufacturing system

下载图片 查看原文

图 2. 光纤激光器原理及掺镱光纤[19]。(a)光纤激光器系统;(b)单模及多模光纤;(c)掺镱光纤的吸收谱和发射谱

Fig. 2. Fiber laser principle and ytterbium-doped fiber[19]. (a) Fiber laser system; (b) single-mode and multi-mode optical fibers;(c) absorption and emission spectra of ytterbium-doped fiber

下载图片 查看原文

图 3. 激光选区熔化成形过程[39-40] 。(a)熔道搭接成形及缺陷形成机理;(b)熔池及飞溅信息

Fig. 3. Process of selective laser melting forming[39-40]. (a) Mechanisms of melting track overlap forming and defects formation; (b) melting pool and spatter information

下载图片 查看原文

图 4. 几种典型的数字化材料及数字化结构样件[43-45]。 (a) 316L/CuSn10双金属结构;(b) 316L拓扑优化FCC/VC/ECC晶格类型多孔结构;(c) CuSn-18Ni300双金属梯度多孔结构

Fig. 4. Several typical digital materials and digital structure samples[43-45]. (a) 316L/CuSn10 bimetal structure; (b) 316L topology optimization of FCC/VC/ECC lattice type porous structures; (c) CuSn-18Ni300 bimetallic gradient porous structure

下载图片 查看原文

图 5. 定向能量沉积技术[10,47]。(a)定向能量沉积技术分类;(b)送丝式定向能量沉积系统

Fig. 5. Directed energy deposition technology[10,47]. (a) Classification of directed energy deposition technology; (b) wire-feed directed energy deposition system

下载图片 查看原文

图 6. 光纤激光器定向能量沉积典型材料成形件。(a) Ti6Al4V合金[58];(b)Ni718合金[61];(c) 227F colmonoy镍基合金[62];(d) 304奥氏体不锈钢[63]; (e) 316LSi不锈钢[66];(f) NiTi合金[67];(g) CrMnFeCoNi高熵合金[68]Fig. 6. Typical materials samples deposited by directed energy deposition with fiber laser. (a) Ti6Al4V alloy[58]; (b) Ni718 alloy[61]; (c) 227-F colmonoy nickel-based alloy[62]; (d) 304 austenite steel[63]; (e) 316LSi stainless steel[66]; (f) NiTi alloy 下载图片 查看原文

表 1粉末床熔融的分类及比较

Table1. Classification and comparison of powder bed fusion

| Method | Activation source | Forming speed | Forming accuracy | Main material type |

|---|

| Selective laser melting | Laser | Slow | High | Metal | | Selective laser sintering | Laser | Fast | High | Polymer | | Electron beam selective melting | Electron beam | Fast | Low | Metal |

|

查看原文

表 2国内外激光选区熔化设备及参数

Table2. Equipment and parameters of domestic and foreign SLM manufacturers

| Company | Model | Build volume /(mm×mm×mm) | Laser power /W | Laser type | Material |

|---|

| SLM solution(GER) | SLM125 | 125×125×125 | 400 | IPG fiberlaser /CW | Stainless steel,Ti6Al4V, AlSi10Mg,IN718, etc. | | SLM500 | 500×280×365 | | 2×4002×700 | | ConceptLaser/GEAdditive(USA) | Mlab Cusing | 50×50×8070×70×8090×90×80 | 100 | Fiber laser /CW | Stainless steel,titanium alloy,aluminum alloy, etc. | | M2 Series 5 | 245×245×350 | | 4002×400 | | DMG MORI(USA) | LASERTEC12 SLM | 125×125×200 | 200400 | Fiber laser /CW | Stainless steel,titanium, aluminumor tool steel, etc. | | LASERTEC30 SLM | 300×300×300 | | 6001000 | | EOS(GER) | EOS M 100 | ϕ100×95 | 200 | Yb fiberlaser /CW | Stainless steel,titanium-based alloys,AlSi10Mg, IN718, etc. | | EOS M 290 | 250×250×325 | | 400 | | EOS M 300 | 300×300×400 | | 4001000 | | EOS M 400 | 400×400×400 | | 1000 | | Renishaw(UK) | RenAM 500 | 250×250×350 | 500 | Fiber laser /CW | Stainless steel, titaniumalloy, aluminum alloy, etc. | | Bright LaserTech (CHN) | BLT-A100 | 100×100×100 | 200 | Fiber laser /CW | Titanium alloy, aluminumalloy, nickel-based alloy,stainless steel, etc. | | BLT-A300 | 250×250×300 | | 500 | | BLT-S400 | 400×250×400 | | 2×500 | | FarsoonTech(CHN) | FS121M | 120×120×100 | 200 | Fiber laser /CW | 316L,CoCrMoW,CoCrMo,CuSn10,IN625,IN718, etc. | | FS271M | 275×275×340 | | 500 | | FS421M | 425×425×420 | | 5002×500 | | Laseradd(CHN) | DiMetal-100 | 100×100×100 | 200 | Yb fiberlaser /CW | Stainless steel, cobaltchromium alloy, Ti6Al4V,AlSi10Mg, IN718, etc. | | DiMetal-280 | 250×250×300 | | 500 | | DiMetal-500 | 500×250×300 | | 2×500 |

|

查看原文

表 3定向能量沉积增材制造领域的4种典型激光器[53]

Table3. Four typical laser in directed energy deposition additive manufacturing field[53]

| Laser parameter | CO2 laser | Nd∶YAG laser | Fiber laser | Semiconductor laser |

|---|

| Wavelength /μm | 10.06 | 1.06 | 1.07 | 0.8-0.98 | | Efficiency /% | 5-20 | LP:1-3DP:10-20 | 10-30 | 30-60 | | Operation mode | CW & pulse | CW & pulse | CW & pulse | CW & pulse | | Output power /W | Up to 20000 | Up to 16000 | Up to 10000 | Up to 4000 | | Pulse energy/pulse duration | 1-10 J/100 ns-10 μs,1 J/~100 ns | Up to 120 J/1-20 ms,1.2 J/~3 ns | Up to 15 J/0.2-20 ms,~mJ/40-500 ns | Single diode, μJ/100 ns (50 kHz) | | Peak power | Tens MW | 50 MW | 10 MW | 40 W | | Beam quality factor /(mm·mrad) | 3-5 | 0.4-20 | 0.3-4 | 10-100 | | Fiber delivery | Not possible | Possible | Possible | Possible | | Maintenance periods | 2000 h | 200 h (lamp life) | Maintenance free,pump diode life isabout 100000 h | Maintenance free,pump diode lifeis about 100000 h |

|

查看原文

表 4国内外定向能量沉积设备及所用激光器

Table4. Directed energy deposition equipment and lasers used at home and abroad

| Equipment manufacturer | Equipment model | Laser power /kW | laser type |

|---|

| OPTOMEC(USA) | LENS systems series | 0.4-3 | Fiber laser/CW | | ADDITEC(USA) | μPrinter | 0.6 | Semiconductor laser | | InssTek(KR) | MX series | 0.3-5 | Yb fiber laser/CW | | DMG MORI(GER) | LASERTEC 65 3D | 2.5,3 | Fiber laser/CW | | TRUMPF (GER) | TruPrint series | 0.2-0.5 | Fiber laser/CW | | Meltio (ESP) | M450 | 0.6 | Solid state laser/CW | | Bright Laser Technologies(CHN) | BLT-C600 | 1,2,4 | Fiber laser/CW | | BLT-C1000 | 2,4,6 | Fiber laser/CW | | TSC(CHN) | TSC-S series | 10 | Fiber laser/CW | | AFS(CHN) | AFS-D600 | 1-3 | Fiber laser/CW | | RAYCHAM(CHN) | RC-LDM2020 | 0.5-4 | Fiber laser/CW | | yNAMT(CHN) | YLC-500 | 2-4 | Semiconductor laser | | TIANYU(CHN) | TY3Z-201703 | 10 | Fiber laser/CW | | Laser Add(CHN) | Laseradd-PR-500 | 6 | Fiber laser/CW | | Laseradd-DED-500H | 1.5 | Semiconductor laser |

|

查看原文

杨永强, 吴世彪, 张越, 朱勇强. 光纤激光器在金属增材制造中的应用进展及展望[J]. 中国激光, 2020, 47(5): 0500012. Yongqiang Yang, Shibiao Wu, Yue Zhang, Yongqiang Zhu. Application Progress and Prospect of Fiber Laser in Metal Additive Manufacturing[J]. Chinese Journal of Lasers, 2020, 47(5): 0500012.

下载: 1933次特邀综述

下载: 1933次特邀综述