农业拖拉机主轴激光熔覆再制造修复研究  下载: 950次

下载: 950次

王家胜, 舒林森. 农业拖拉机主轴激光熔覆再制造修复研究[J]. 激光与光电子学进展, 2020, 57(7): 071404.

Jiasheng Wang, Linsen Shu. Laser Cladding Remanufacturing and Repair of Agricultural Tractor Spindle[J]. Laser & Optoelectronics Progress, 2020, 57(7): 071404.

[1] 徐滨士, 夏丹, 谭君洋, 等. 中国智能再制造的现状与发展[J]. 中国表面工程, 2018, 31(5): 1-13.

Xu B S, Xia D, Tan J Y, et al. Status and development of intelligent remanufacturing in China[J]. China Surface Engineering, 2018, 31(5): 1-13.

[2] 谢斌, 武仲斌, 毛恩荣. 农业拖拉机关键技术发展现状与展望[J]. 农业机械学报, 2018, 49(8): 1-17.

Xie B, Wu Z B, Mao E R. Development and prospect of key technologies on agricultural tractor[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(8): 1-17.

[3] 白学峰, 杨浩勇, 常江雪. 履带拖拉机发展现状分析与发展建议思考[J]. 拖拉机与农用运输车, 2017, 44(6): 1-4, 6.

Bai X F, Yang H Y, Chang J X. Present situation analysis and development suggestion of crawler tractor[J]. Tractor & Farm Transporter, 2017, 44(6): 1-4, 6.

[4] 马戈, 毛长恩, 孔春花, 等. 感应热处理工艺对拖拉机轴类零件扭转强度的影响[J]. 拖拉机与农用运输车, 2014, 41(1): 70-73.

Ma G, Mao C E, Kong C H, et al. Effects of induction heating process on torsional strength of tractor shaft parts[J]. Tractor & Farm Transporter, 2014, 41(1): 70-73.

[5] Skarvelis P, Papadimitriou G D. Plasma transferred arc composite coatings with self lubricating properties, based on Fe and Ti sulfides: Microstructure and tribological behavior[J]. Surface and Coatings Technology, 2009, 203(10/11): 1384-1394.

[8] 陆小龙, 刘秀波, 余鹏程, 等. 后热处理对304不锈钢激光熔覆Ni60/h-BN自润滑耐磨复合涂层组织和摩擦学性能的影响[J]. 摩擦学学报, 2016, 36(1): 48-54.

Lu X L, Liu X B, Yu P C, et al. Effects of post heat-treatment on microstructure and tribological properties of Ni60/H-BN self-lubricating anti-wear composite coating on 304 stainless steel by laser cladding[J]. Tribology, 2016, 36(1): 48-54.

[9] 封慧, 李剑峰, 孙杰. 曲轴轴颈损伤表面的激光熔覆再制造修复[J]. 中国激光, 2014, 41(8): 0803003.

[10] 韩玉勇, 鲁俊杰, 李剑峰, 等. 基于激光熔覆的车床主轴再制造[J]. 中国表面工程, 2015, 28(6): 147-153.

Han Y Y, Lu J J, Li J F, et al. Lathe spindle remanufacturing based on laser cladding technology[J]. China Surface Engineering, 2015, 28(6): 147-153.

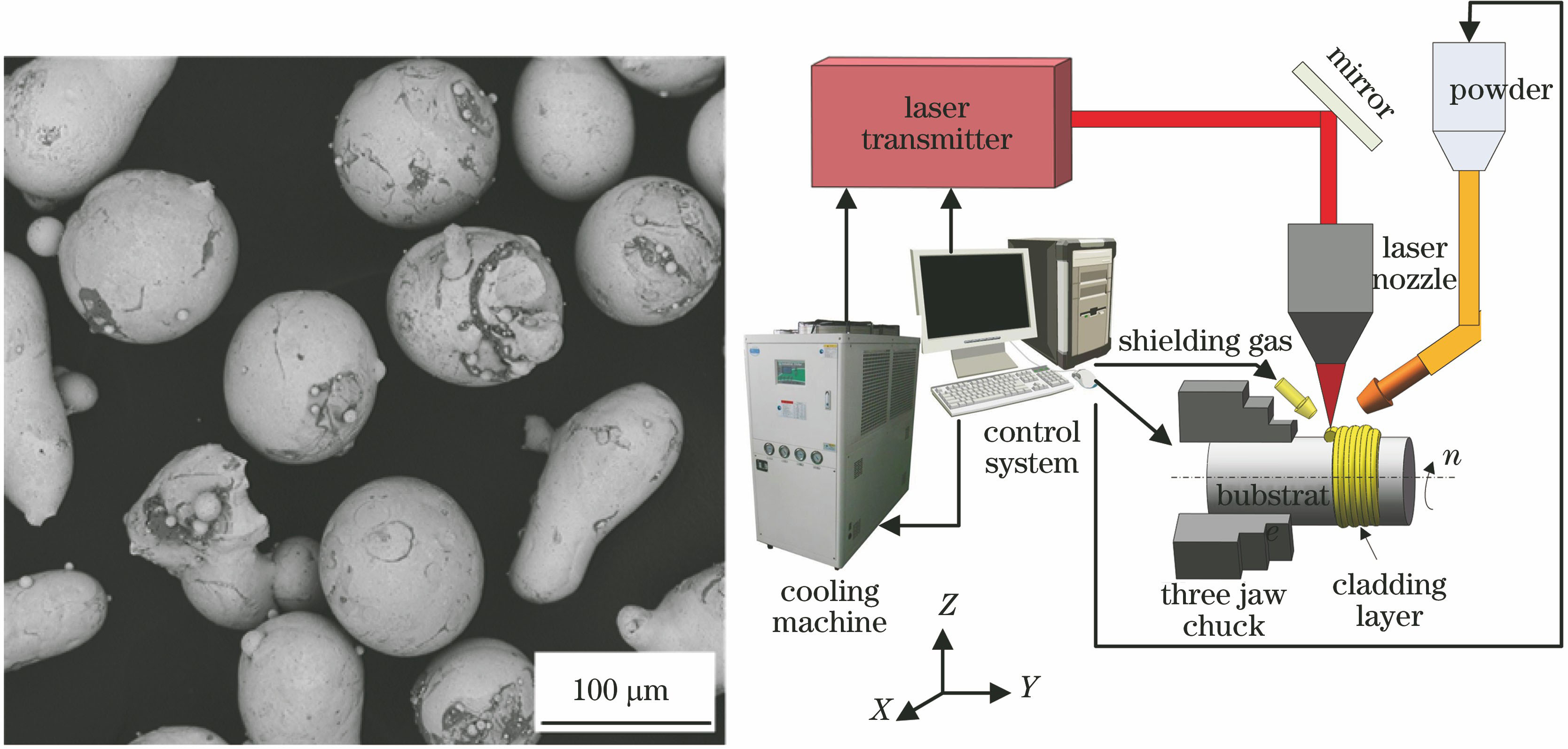

[11] 舒林森, 王家胜, 白海清, 等. 磨损轴面激光熔覆过程的数值模拟及试验[J]. 机械工程学报, 2019, 55(9): 217-223.

Shu L S, Wang J S, Bai H Q, et al. Numerical and experimental investigation on laser cladding treatment of wear shaft surface[J]. Journal of Mechanical Engineering, 2019, 55(9): 217-223.

[12] 任维彬, 董世运, 徐滨士, 等. 压缩机叶片激光再制造成形闭环控制设计与实现[J]. 焊接学报, 2018, 39(3): 11-15, 129.

Ren W B, Dong S Y, Xu B S, et al. Design and implementation of laser refabrication forming closed-loop controlling for compressor blade[J]. Transactions of the China Welding Institution, 2018, 39(3): 11-15, 129.

[13] 黄海博, 孙文磊, 张冠, 等. 基于NURBS曲面的汽轮机叶片激光熔覆再制造路径规划[J]. 中国表面工程, 2018, 31(5): 175-183.

Huang H B, Sun W L, Zhang G, et al. Path trajectory of laser cladding remanufacturing for turbine blade based on NURBS surface[J]. China Surface Engineering, 2018, 31(5): 175-183.

[14] 曹俊, 卢海飞, 鲁金忠, 等. WC对激光熔覆热作模具的组织和磨损性能的影响[J]. 中国激光, 2019, 46(7): 0702001.

[15] 徐鹏, 董梁, 鞠恒, 等. 激光熔覆304不锈钢涂层的组织及耐蚀性[J]. 材料热处理学报, 2014, 35(S1): 221-225.

Xu P, Dong L, Ju H, et al. Microstructure and corrosion resistance of 304 stainless steel coating by laser cladding[J]. Transactions of Materials and Heat Treatment, 2014, 35(S1): 221-225.

[16] 李闯, 刘洪喜, 张晓伟, 等. 40Cr刀具钢表面激光熔覆钴基碳化物复合涂层的组织与性能[J]. 中国激光, 2015, 42(11): 1103002.

[17] 叶四友, 刘建永, 杨伟. 激光熔覆316L不锈钢涂层组织和性能的研究[J]. 表面技术, 2018, 47(3): 48-53.

Ye S Y, Liu J Y, Yang W. Microstructure and properties of laser cladded 316L stainless steel layer[J]. Surface Technology, 2018, 47(3): 48-53.

王家胜, 舒林森. 农业拖拉机主轴激光熔覆再制造修复研究[J]. 激光与光电子学进展, 2020, 57(7): 071404. Jiasheng Wang, Linsen Shu. Laser Cladding Remanufacturing and Repair of Agricultural Tractor Spindle[J]. Laser & Optoelectronics Progress, 2020, 57(7): 071404.