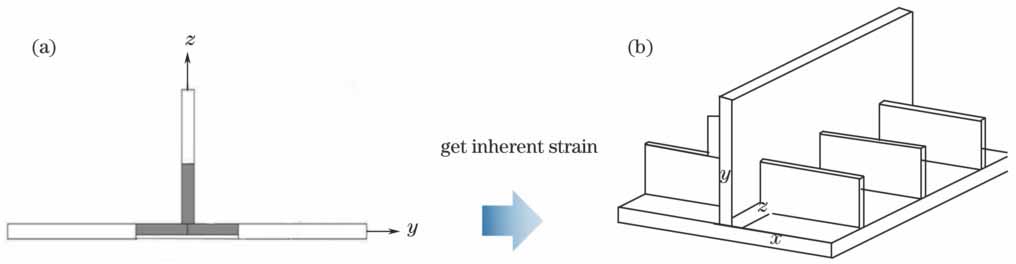

基于固有应变法的激光选区熔化成形变形趋势预测  下载: 1048次

下载: 1048次

倪辰旖, 张长东, 刘婷婷, 廖文和. 基于固有应变法的激光选区熔化成形变形趋势预测[J]. 中国激光, 2018, 45(7): 0702004.

Chenyi Ni, Changdong Zhang, Tingting Liu, Wenhe Liao. Deformation Prediction of Metal Selective Laser Melting Based on Inherent Strain Method[J]. Chinese Journal of Lasers, 2018, 45(7): 0702004.

[1] 李吉帅, 戚文军, 李亚江, 等. 选区激光熔化工艺参数对Ti-6Al-4V成形质量的影响[J]. 材料导报, 2017, 31(5): 65-69.

李吉帅, 戚文军, 李亚江, 等. 选区激光熔化工艺参数对Ti-6Al-4V成形质量的影响[J]. 材料导报, 2017, 31(5): 65-69.

Li J S, Qi W J, Li Y J, et al. Influence of process parameters of forming characteristics on Ti-6Al-4V fabricated by selective laser melting[J]. Materials Review, 2017, 31(5): 65-69.

[2] 陈德宁, 刘婷婷, 廖文和, 等. 扫描策略对金属粉末选区激光熔化温度场的影响[J]. 中国激光, 2016, 43(4): 0403003.

陈德宁, 刘婷婷, 廖文和, 等. 扫描策略对金属粉末选区激光熔化温度场的影响[J]. 中国激光, 2016, 43(4): 0403003.

[3] 陈帅, 陶凤和, 贾长治, 等. H13模具钢选区激光熔化成型工艺及其性能研究[J]. 热加工工艺, 2017, 46(10): 162-165.

陈帅, 陶凤和, 贾长治, 等. H13模具钢选区激光熔化成型工艺及其性能研究[J]. 热加工工艺, 2017, 46(10): 162-165.

Chen S, Tao F H, Jia C Z, et al. Research on selective laser melting forming process and property of H13 die steel[J]. Hot Working Technology, 2017, 46(10): 162-165.

[4] 张凯, 刘婷婷, 张长东, 等. 基于熔池数据分析的激光选区熔化成形件翘曲变形行为研究[J]. 中国激光, 2015, 42(9): 0903007.

张凯, 刘婷婷, 张长东, 等. 基于熔池数据分析的激光选区熔化成形件翘曲变形行为研究[J]. 中国激光, 2015, 42(9): 0903007.

[7] 姚化山, 史玉升, 章文献, 等. 金属粉末选区激光熔化成形过程温度场模拟[J]. 应用激光, 2007, 27(6): 456-460.

姚化山, 史玉升, 章文献, 等. 金属粉末选区激光熔化成形过程温度场模拟[J]. 应用激光, 2007, 27(6): 456-460.

[8] Ueda Y, Yuan M G. A predicting method of welding residual stress using source of residual stress[J]. Quarterly Journal of the Japan Welding Society, 1991, 9(3): 337-343.

Ueda Y, Yuan M G. A predicting method of welding residual stress using source of residual stress[J]. Quarterly Journal of the Japan Welding Society, 1991, 9(3): 337-343.

[10] 周晶, 常保华, 张骅, 等. 采用固有应变法预测铝合金焊接变形[J]. 焊接技术, 2010, 39(6): 6-10.

周晶, 常保华, 张骅, 等. 采用固有应变法预测铝合金焊接变形[J]. 焊接技术, 2010, 39(6): 6-10.

Zhou J, Chang B H, Zhang H, et al. Study on the prediction of welding distortion of aluminium alloy based on inherent strain method[J]. Welding Technology, 2010, 39(6): 6-10.

[11] 魏天冬. T型构件焊接固有应变的研究及应用[D]. 秦皇岛: 燕山大学, 2011.

魏天冬. T型构件焊接固有应变的研究及应用[D]. 秦皇岛: 燕山大学, 2011.

Wei TD. The study and applications of T-component welding inherent strain[D]. Qinhuangdao: Yanshan University, 2011.

Wei TD. The study and applications of T-component welding inherent strain[D]. Qinhuangdao: Yanshan University, 2011.

[12] KellerN, PloshikhinV. New method for fast predictions of residual stress and distortion of AM parts[C]. Solid Freeform Fabrication Symposium, 2014: 1229- 1237.

KellerN, PloshikhinV. New method for fast predictions of residual stress and distortion of AM parts[C]. Solid Freeform Fabrication Symposium, 2014: 1229- 1237.

[13] 汪建华, 陆皓, 魏良武. 固有应变有限元法预测焊接变形理论及其应用[J]. 焊接学报, 2002, 23(6): 36-40.

汪建华, 陆皓, 魏良武. 固有应变有限元法预测焊接变形理论及其应用[J]. 焊接学报, 2002, 23(6): 36-40.

Wang J H, Lu H, Wei L W. Prediction of welding distortions based on theory of inherent strain by FEM and its application[J]. Transactions of the China Welding Institution, 2002, 23(6): 36-40.

[16] 董志波, 刘雪松, 马瑞, 等. MSC.Marc工程实例详解[M]. 北京: 人民邮电出版社, 2014.

董志波, 刘雪松, 马瑞, 等. MSC.Marc工程实例详解[M]. 北京: 人民邮电出版社, 2014.

Dong ZB, Liu XS, MaR, et al.Detailed solution of MSC.Marc engineering example[M]. Beijing: Posts and Telecom Press, 2014.

Dong ZB, Liu XS, MaR, et al.Detailed solution of MSC.Marc engineering example[M]. Beijing: Posts and Telecom Press, 2014.

[17] 黄辉, 赵耀, 袁华. 平板焊接变形预测固有应变方法的研究[ C]. 第五届中国CAE工程分析技术年会, 2009: 748- 755.

黄辉, 赵耀, 袁华. 平板焊接变形预测固有应变方法的研究[ C]. 第五届中国CAE工程分析技术年会, 2009: 748- 755.

HuangH, ZhaoY, YuanH, et al. Study on inherent strain prediction method for plate welding deformation[ C]. The 5 th China Annual Conference on CAE Engineering Analysis Technology , 2009: 748- 755.

HuangH, ZhaoY, YuanH, et al. Study on inherent strain prediction method for plate welding deformation[ C]. The 5 th China Annual Conference on CAE Engineering Analysis Technology , 2009: 748- 755.

倪辰旖, 张长东, 刘婷婷, 廖文和. 基于固有应变法的激光选区熔化成形变形趋势预测[J]. 中国激光, 2018, 45(7): 0702004. Chenyi Ni, Changdong Zhang, Tingting Liu, Wenhe Liao. Deformation Prediction of Metal Selective Laser Melting Based on Inherent Strain Method[J]. Chinese Journal of Lasers, 2018, 45(7): 0702004.