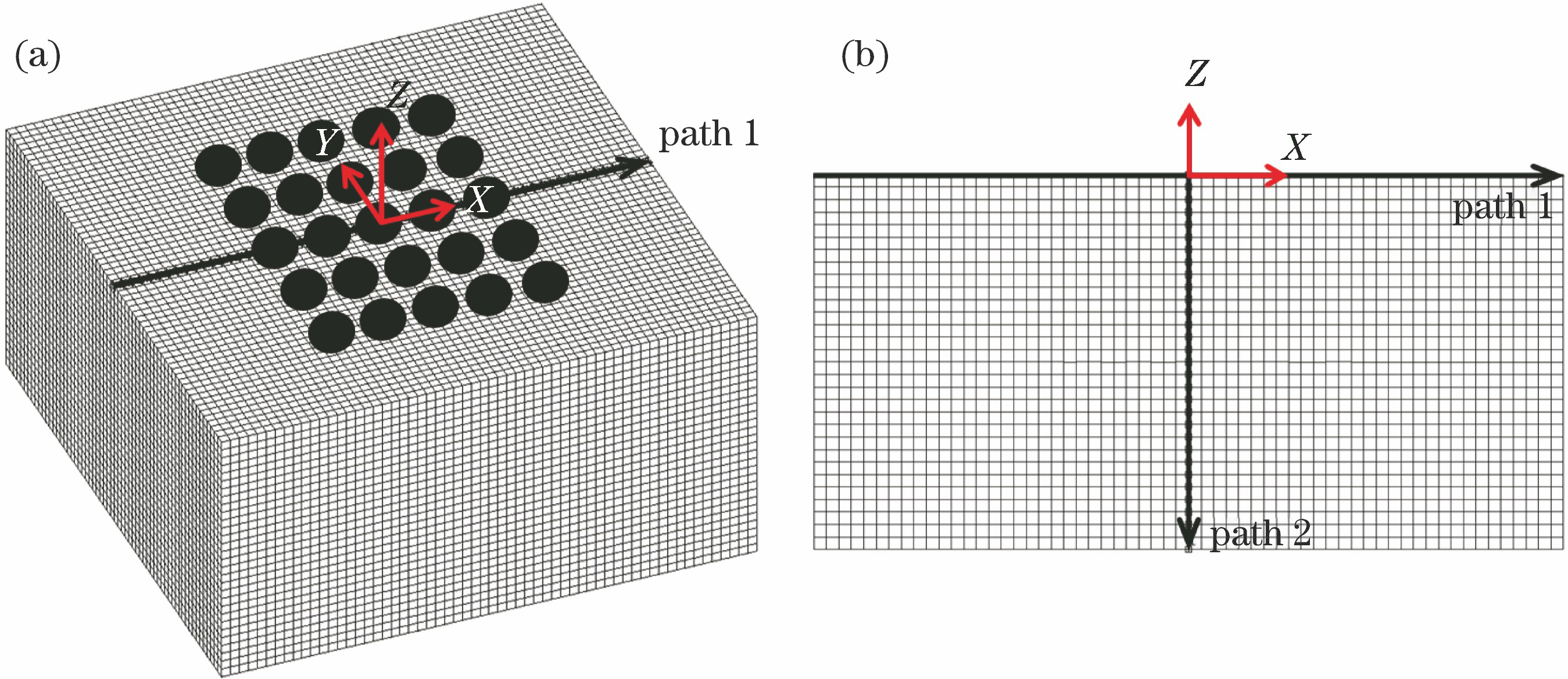

离散激光相变硬化蠕墨铸铁应力场数值模拟  下载: 799次

下载: 799次

庞铭, 谭雯丹. 离散激光相变硬化蠕墨铸铁应力场数值模拟[J]. 激光与光电子学进展, 2019, 56(23): 231403.

Ming Pang, Wendan Tan. Numerical Simulation of Stress Field of Laser Phase Transformation Hardening Vermicular Graphite Cast Iron Based on Beam Discretization[J]. Laser & Optoelectronics Progress, 2019, 56(23): 231403.

[1] Pina J C, Shafqat S, Kouznetsova V G, et al. Microstructural study of the mechanical response of compacted graphite iron: an experimental and numerical approach[J]. Materials Science and Engineering: A, 2016, 658: 439-449.

[2] Kim S, Cockcroft S L, Omran A M, et al. Mechanical, wear and heat exposure properties of compacted graphite cast iron at elevated temperatures[J]. Journal of Alloys and Compounds, 2009, 487(1/2): 253-257.

[3] 谭雯丹, 庞铭, 江国业, 等. 高强化柴油机气门座激光相变硬化温度场的数值模拟[J]. 激光与光电子学进展, 2018, 55(11): 111601.

[4] 吴王平, 刘剑文, 王辉, 等. 激光熔覆NiAl-SiC复合涂层的组织与摩擦性能[J]. 激光与光电子学进展, 2018, 55(9): 091406.

[5] 王洪建, 李永亮, 李平. 激光切割AZ31B镁铝合金正交实验研究[J]. 激光与光电子学进展, 2018, 55(10): 101405.

[6] 刘亚楠, 孙荣禄, 张天刚, 等. CeO2含量对激光熔覆自润滑涂层微观组织和性能的影响[J]. 激光与光电子学进展, 2018, 55(11): 111401.

[7] 虞钢, 聂树真, 郑彩云, 等. 用于激光加工中的矩形孔径Dammann光栅光束变换技术[J]. 中国激光, 2008, 35(11): 1841-1847.

[8] 巴发海, 甘翠华, 吴炜, 等. 球铁材料脉冲激光表面强化的实验研究[J]. 中国激光, 2003, 30(7): 663-667.

[9] 李正阳, 钟敏霖, 张红军, 等. 激光点状合金化对42CrMo钢疲劳裂纹扩展速率的影响[J]. 应用激光, 2007, 27(1): 1-4.

[10] 王海龙. 球墨铸铁热轧辊表面激光点状合金化技术研究[D]. 北京: 清华大学, 2007.

Wang HL. The investigation on spot array laser alloying on nodular cast iron hot roller[D]. Beijing: Tsinghua University, 2007.

[11] SprangerF, Hilgenberg K. Dispersion behavior of TiB2 particles in AISI D2 tool steel surfaces during pulsed laser dispersing and their influence on material properties[J]. Applied Surface Science, 2019, 467/468: 493- 504.

[12] 庞铭, 谭雯丹, 付威, 等. 激光相变硬化蠕墨铸铁气门座应力场数值模拟研究[J]. 热加工工艺, 2018, 47(24): 218-222, 225.

Pang M, Tan W D, Fu W, et al. Numerical simulation study on stress field of laser transformation hardening vermicular graphite cast iron valve seat[J]. Hot Working Technology, 2018, 47(24): 218-222, 225.

[13] 庞铭, 谭雯丹. 基于光束离散的激光相变硬化蠕墨铸铁温度场数值模拟[J]. 激光与光电子学进展, 2019, 56(19): 191404.

[14] 张哲. 泵筒内壁激光相变硬化数值模拟及催渗机理研究[D]. 东营: 中国石油大学( 华东), 2013.

ZhangZ. Numerical simulation of laser transformation hardening on the inner wall of pump barrel and study on the mechanism of rapid nitriding[D]. Dongying: China University of Petroleum ( Huadong), 2013.

[15] 张哲, 韩彬, 王勇, 等. 工件形状对激光相变硬化温度场和应力场的影响[J]. 中国激光, 2012, 39(8): 0803001.

[16] 龚丞, 王丽芳, 朱刚贤, 等. 激光增材制造316L不锈钢熔覆层残余应力的数值模拟研究[J]. 应用激光, 2018, 38(3): 402-408.

[17] 卞宏友, 翟泉星, 曲伸, 等. 基体预热下激光沉积修复GH4169合金温度场和应力场演变[J]. 应用激光, 2017, 37(3): 327-332.

[18] 姚国凤, 陈光南. 激光熔凝加工中瞬时温度场及残余应力数值模拟[J]. 应用激光, 2002, 22(2): 241-243, 222.

Yao G F, Chen G N. Numerical simulation of transient thermal field and residual stress in laser melting process[J]. Applied Laser, 2002, 22(2): 241-243, 222.

[19] 李美艳, 韩彬, 蔡春波, 等. 36(5): 25-28[J]. . 激光熔覆镍基合金温度场和应力场数值模拟. 焊接学报, 2015, 32: 114.

Li M Y, Han B, Cai C B, et al. 36(5): 25-28[J]. stress fields of laser cladded Ni-based coating. Transactions of the China Welding Institution, 2015, 32: 114.

[20] 顾建强, 骆芳, 姚建华. 激光熔覆过程残余应力的数值模拟[J]. 激光与光电子学进展, 2010, 47(10): 101401.

[21] 文舒, 董安平, 陆燕玲, 等. GH536高温合金选区激光熔化温度场和残余应力的有限元模拟[J]. 金属学报, 2018, 54(3): 393-403.

Wen S, Dong A P, Lu Y L, et al. Finite element simulation of the temperature field and residual stress in GH536 superalloy treated by selective laser melting[J]. Acta Metallurgica Sinica, 2018, 54(3): 393-403.

庞铭, 谭雯丹. 离散激光相变硬化蠕墨铸铁应力场数值模拟[J]. 激光与光电子学进展, 2019, 56(23): 231403. Ming Pang, Wendan Tan. Numerical Simulation of Stress Field of Laser Phase Transformation Hardening Vermicular Graphite Cast Iron Based on Beam Discretization[J]. Laser & Optoelectronics Progress, 2019, 56(23): 231403.