δ时效处理对激光增材修复Inconel 718合金组织与性能的影响  下载: 1314次

下载: 1314次

张杰, 张群莉, 李栋, 童文华, 姚建华, 冷志斌. δ时效处理对激光增材修复Inconel 718合金组织与性能的影响[J]. 中国激光, 2020, 47(1): 0102001.

Jie Zhang, Qunli Zhang, Dong Li, Wenhua Tong, Jianhua Yao, Zhibin Leng. Effect of δ Aging Treatment on Microstructure and Tensile Properties of Repaired Inconel 718 Alloy Using Laser Additive Manufacturing[J]. Chinese Journal of Lasers, 2020, 47(1): 0102001.

[1] 赵卫卫, 林鑫, 刘奋成, 等. 热处理对激光立体成形Inconel 718高温合金组织和力学性能的影响[J]. 中国激光, 2009, 36(12): 3220-3225.

[2] 魏先平, 郑文杰, 宋志刚, 等. 热处理对Inconel 718合金组织及力学性能的影响[J]. 材料热处理学报, 2012, 33(8): 53-58.

Wei X P, Zheng W J, Song Z G, et al. Effects of heat treatment on microstructure and mechanical properties of Inconel 718 alloy[J]. Transactions of Materials and Heat Treatment, 2012, 33(8): 53-58.

[3] 牛静, 张凡云, 杨树林, 等. 不同时效处理对GH4169合金组织性能的影响[J]. 航空制造技术, 2016( 20): 45- 48.

NiuJ, Zhang FY, Yang SL, et al. Effects of aging treatments on the microstructure and mechanical properties of GH4169 alloy[J]. Aeronautical Manufacturing Technology, 2016( 20): 45- 48.

[4] Zhang Q L, Yao J H, Mazumder J. Laser direct metal deposition technology and microstructure and composition segregation of Inconel 718 superalloy[J]. Journal of Iron and Steel Research International, 2011, 18(4): 73-78.

[5] Zhang Y C, Li Z G, Nie P L, et al. Effect of ultrarapid cooling on microstructure of laser cladding IN718 coating[J]. Surface Engineering, 2013, 29(6): 414-418.

[6] 冯晓甜, 顾宏, 周圣丰, 等. 送粉式激光增材制造TC4钛合金熔覆层组织及电化学腐蚀行为的研究[J]. 中国激光, 2019, 46(3): 0302003.

[7] 魏菁, 李雅莉, 何艳丽, 等. Hastelloy-X粉末成分对激光选区熔化成形各向成形性能的影响[J]. 中国激光, 2018, 45(12): 1202011.

[8] 于群, 王存山. 电磁搅拌辅助Ni45合金的激光增材制造[J]. 中国激光, 2018, 45(4): 0402003.

[9] 赵剑峰, 成诚, 谢得巧, 等. 激光修复GH4169镍基高温合金的高温拉伸性能[J]. 中国激光, 2016, 43(8): 0802012.

[10] 卞宏友, 赵翔鹏, 曲伸, 等. 热处理对激光沉积修复GH4169合金高温性能的影响[J]. 中国激光, 2016, 43(1): 0103008.

[11] 卞宏友, 赵翔鹏, 杨光, 等. 激光沉积修复GH4169合金热处理的组织及性能[J]. 中国激光, 2015, 42(12): 1206001.

[12] 刘奋成, 吕飞阅, 任航, 等. 激光立体成形Inconel 718镍基高温合金δ相析出规律[J]. 中国激光, 2018, 45(12): 1202009.

[13] Sui S, Chen J, Ma L, et al. Microstructures and stress rupture properties of pulse laser repaired Inconel 718 superalloy after different heat treatments[J]. Journal of Alloys and Compounds, 2019, 770: 125-135.

[14] 张杰, 张群莉, 陈智君, 等. 固溶温度对激光增材制造Inconel 718合金组织和性能的影响[J]. 表面技术, 2019, 48(2): 47-53.

Zhang J, Zhang Q L, Chen Z J, et al. Effects of solution temperature on microstructure and properties of Inconel 718 alloy fabricated via laser additive manufacturing[J]. Surface Technology, 2019, 48(2): 47-53.

[15] 申佳林. GH4169合金中δ相析出特征及其对焊缝断裂性能影响规律研究[D]. 贵阳: 贵州大学, 2018: 22- 33.

Shen JL. Study on the characteristics of δ phase precipitation and its effect on welding seam fracture in GH4169 alloy[D]. Guiyang: Guizhou University, 2018: 22- 33.

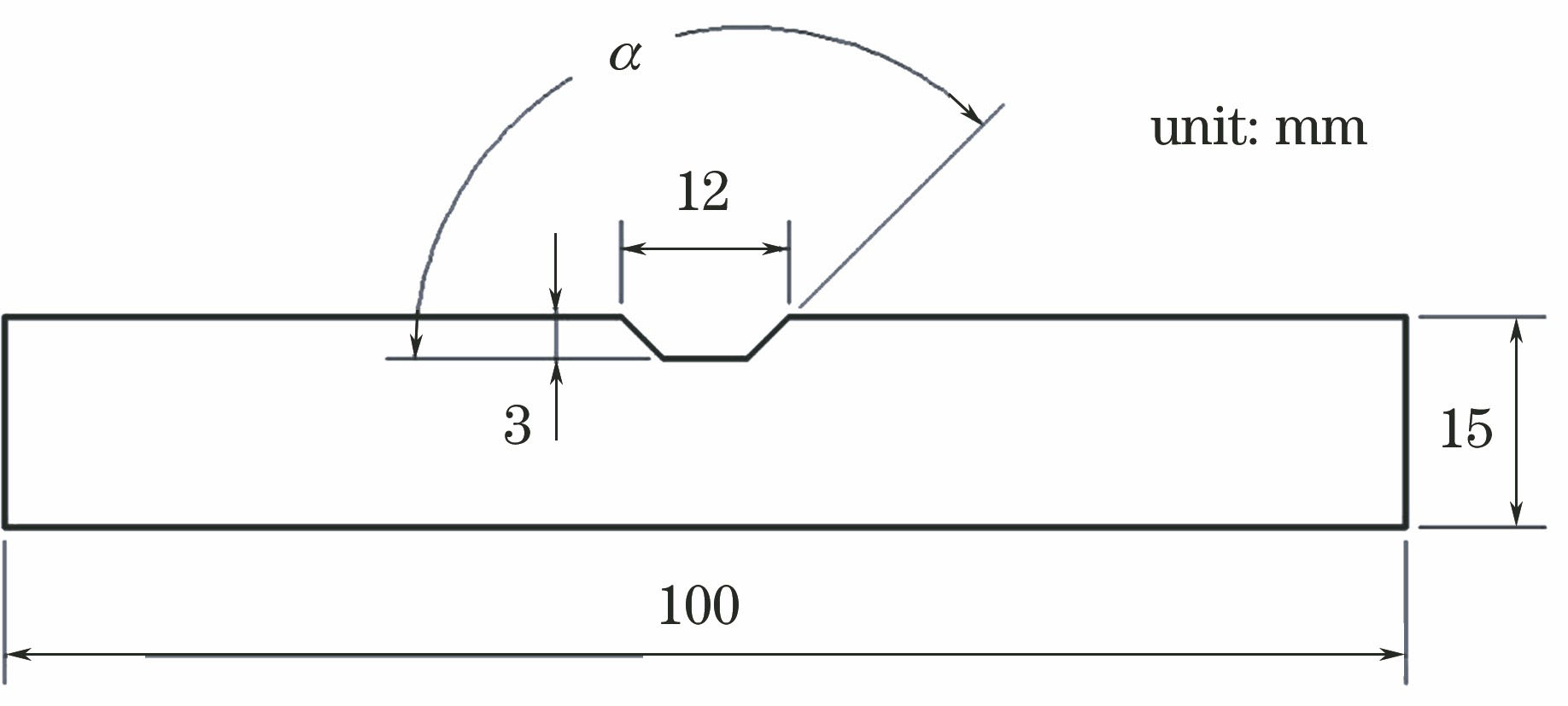

[16] 张群莉, 李栋, 张杰, 等. 预制坡口角度对激光增材再制造IN718合金组织与性能的影响[J]. 表面技术, 2019, 48(5): 90-96.

Zhang Q L, Li D, Zhang J, et al. Influence of pre-fabricated groove angle on microstructure and properties of laser additive remanufactured IN718 alloy[J]. Surface Technology, 2019, 48(5): 90-96.

[17] 邸新杰, 邢希学, 王宝森. Inconel 625熔敷金属中δ相的形核与粗化机理[J]. 金属学报, 2014, 50(3): 323-328.

Di X J, Xing X X, Wang B S. Nucleation and coarsening mechanism of δ phase in Inconel 625 deposited metal[J]. Acta Metallurgica Sinica, 2014, 50(3): 323-328.

[18] 张京玲. δ相对GH4169合金的组织演化和性能影响[D]. 天津: 天津大学, 2017: 23- 32.

Zhang JL. Effect of δ-phase on the microstructural evolution and properties of GH4169 alloy[D]. Tianjin: Tianjin University, 2017: 23- 32.

[19] 李亚敏, 朱瑞明, 刘洪军, 等. 长时间时效对GH625合金析出相和拉伸性能的影响[J]. 中国有色金属学报, 2019, 29(2): 262-269.

Li Y M, Zhu R M, Liu H J, et al. Effect of long-time aging on precipitated phase and tensile properties of GH625 alloy[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(2): 262-269.

张杰, 张群莉, 李栋, 童文华, 姚建华, 冷志斌. δ时效处理对激光增材修复Inconel 718合金组织与性能的影响[J]. 中国激光, 2020, 47(1): 0102001. Jie Zhang, Qunli Zhang, Dong Li, Wenhua Tong, Jianhua Yao, Zhibin Leng. Effect of δ Aging Treatment on Microstructure and Tensile Properties of Repaired Inconel 718 Alloy Using Laser Additive Manufacturing[J]. Chinese Journal of Lasers, 2020, 47(1): 0102001.