On-chip readout plasmonic mid-IR gas sensor  Download: 737次

Download: 737次

1 Introduction

There are growing interests for gas sensing such as greenhouse gas monitoring1, indoor air quality supervision2, automobile tail gas discharge detection3, toxic or flammable gases detection4, breath diagnostics5, industrial production6, etc. So far, several major approaches have been developed7, including electrochemical sensors8, calorimetric sensors9, acoustic sensors10 and optical sensors11. Optical methods12, in particular in the mid-IR range, are usually straightforward and have short response time, long lifetime, high sensitivity and selectivity. Generally, there are three mechanisms for optical gas sensing, including (i) refractive index (RI) sensing based on the real part of gas RI13, (ii) non-dispersive infrared (NDIR) absorption sensing based on the imaginary part of gas RI14, and (iii) spectroscopy based on the gas molecular spectral fingerprint15. The RI sensing method allows for characterization of nonreactive gases and very compact sensor design. However, this technique such as surface plasmon resonance (SPR)16 sensors that are widely used in liquid and solid detection suffers sensitivity issues for gas sensing due to the low RI difference (~10-4 RIU) between various gases. For example, a localized SPR spectroscopy was developed with a detection limit level about 3×10-4 RIU that only showed measurable signal between pure Ar and He17. An air-slot photonic crystal nanocavities was used to enhance the light-gas interaction, but a similar RI detection limit of 10-5 RIU was estimated considering a 3 pm spectral measuring resolution18. As a result, some signal amplification techniques were developed. For example, silicon glycol copolymer was used in a standard SPR setup to enrich halothane and reduce the detection limit down to 80 ppm, where both thickness and RI of the copolymer are affected by the gas absorption19. Similarly, Pd20, carbon nanotube21, and SnO2 microspheres22 are also widely used to increase the RI variations by chemical reactions. In contrast, NDIR absorption sensing method is more popular23. This technique is based on the Beer–Lambert Law, and thus the sensitivity can be increased by simply lengthening the optical path for light-gas interaction. For example, a detection limit for formaldehyde of 120 pptv was demonstrated by using an antimonide laser and a 1 m base-length cell with a multipass path lengths of 100 m by mirrors24. Ethyl chloride gas at a 5 ppm concentration level was detected by using a distributed-feedback quantum cascade laser (QCL) coupled with a silica capillary with a length of 4 m25. Instead of laser sources, the NDIR sensing system can also be built with a broadband source, narrowband filter and detector. For example, a detection limit of 50 ppm was predicted in an ellipsoid gas cell system with a LED source and PbSe detector26. No matter which configuration, due to the low molecular absorption cross-sections of mid-IR vibrations (10−20 cm2), the whole system is bulky to ensure a high sensitivity and therefore limited for integrated applications.

Recently, nanophotonic structures have attracted extensive interests in optical sensing fields27, 28. Novel designs and excellent sensing performances have been demonstrated due to their remarkable electromagnetic field enhancement29, spectral manipulating30, chirality31 and phase32 engineering, etc. Some pioneered works have also explored mid-IR gas sensing. By manipulating the spatial electromagnetic field distribution, a detection limit of 60000 ppm for CO2 was demonstrated in a 4 mm long gas cell device containing a metal microstructure array, which provides a 1100 times absorption enhancement in the optical path together with a porous metal-organic framework (MOF)33. By engineering the emission spectrum, an NDIR sensor with a narrowband thermal emitter based on plasmonic crystal was demonstrated with a detection limit of 10000 ppm for CO2 in a 7.5 mm gas cell34. Similarly, the detection wavelength can also be engineered by integrating microstructure filters with the detector23, 25, in which case it can form a sensing system with a low-cost broadband source. Although all these works demonstrated promising developments, the nanophotonic mid-IR gas sensors still suffer some major issues, 1) the detection limit is too high for low concentration gas detection, 2) the linewidth of either emitter or detector is too large with a quality (Q) factor < 10 and limits the device figure of merit, 3) a lack of spectroscopic analysis, and 4) the gas cell is still not compact.

In this article, a novel mid-IR gas sensor consisting of a narrowband plasmonic absorber integrated with a thermal detector is proposed to address these issues. The shallow metal grating structure is adopted and found to provide a high Q factor resonance and strongly localized resonant field, which ensures a high sensitivity even at a limited light-gas interaction length. The combination of the optical resonator and thermal detector offers on-chip direct readout for portable gas sensors. Thoughtful investigation based on both optical and thermal simulation reveals the significant enhancement on the sensitivity via both SPR and MOF. The on-chip spectroscopy with an ultrahigh spectral resolution is also demonstrated by using a narrowband sensor array with the help of compressive sensing algorithm. In addition, the size effect existing in most periodic plasmonic structure is investigated considering the practical applications and a potential solution is discussed.

2 Mechanism and design

2.1 Mechanism

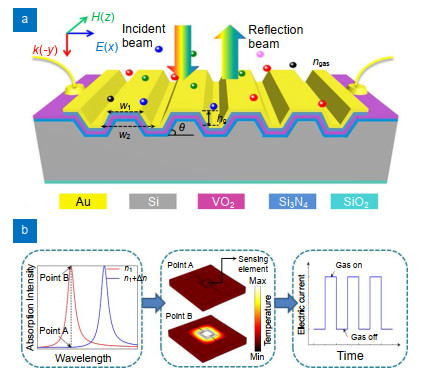

Conventionally, the gas sensing system needs a bulky gas chamber to ensure a strong light-gas interaction for low detection limit36-38. As is well known, micro-resonators are usually used to enhance the light-matter interaction30, which is able to reduce the sensor dimensions for distributed or low-load platform while keeping a high performance. To construct a high sensitivity, compact gas sensor for on-site application, it is important to integrate separated elements into a single multi-functional component. Moreover, the performance is maintained or even improved by an optimal combination of different functions. Inspired by the previous work on microfluidic integrated metamaterial 'flowing through' sensor29 and color routing metal scatters integrated silicon optoelectronic device39, a novel mid-IR gas sensor is proposed as shown in

Fig. 1. (a ) Schematic of a multilayer stack (Au/Si3N4/VO2/Si3N4) coated silicon gratings for on-chip gas sensing. (b ) Sensing mechanism. The variation of gas concentration induces an increase/decrease of light absorbance of the microstructures and then causes a temperature increase/decrease, which generates an electrical signal via VO2.

For a high sensing performance, it needs to optimize both optical and electrical design to integrate efficiently. From the optical sensing perspective, the larger change of the light absorption at the same gas concentration variation, the stronger the detection signal. To achieve this, a resonator with a narrowband and efficient absorption is required in a broadband wavelength range. The wavelength selective detection also increases the gas selectivity. From the electrical transducing perspective, although the photodetectors based on compound semiconductors usually have high detectivity in the mid-IR range40, it is too expensive and not compatible to the CMOS process. Thermal detectors with a reasonably good sensitivity attract lots of attention due to the simplicity and low cost41. Obviously, the more efficient of the heat induced resistance variation, the stronger electric current signal, i.e. the device is more sensitive. To achieve this, a thermal resistance material with a large temperature coefficient of resistance and low 1/f noise such as VO2 is chosen and fabricated adjacent to a thermal source. To connect optical and electrical perspectives, the on-resonance light absorption is converted to photocurrent in such a Au/Si3N4/VO2/Si3N4 multilayer thermal resistor.

However, it is not straightforward to achieve a narrowband resonant absorption with a large Q factor. In fact, the Q factors are very low for most plasmonic and metamaterial absorbers based on periodic metal structures although they usually have strong light-matter interaction29, 42. For example, the microfluidic metamaterial sensor has a resonant absorption with a Q factor less than 1029 and a SPR photodetector has a resonant absorption with a Q factor about 1543. Fano resonance44, asymmetrical unit cell45 and even gain material46were used to increase the Q factor. Generally, the Q factor associates with radiation loss and absorption loss in a resonant system16, 47. It is important to reduce both losses to realize a high Q factor. The absorption is associated with the ohmic loss. Although TiN, AZO and graphene have been investigated as alternative plasmonic materials, noble metals are still the main materials to construct plasmonic or metamaterial absorbers, where Au and Ag have relatively low absorption loss. On the other hand, the radiation loss can be reduced to zero in a flat layered structure. Therefore, the radiation loss in a resonator configuration as shown in

VO2 is a typical thermal resistance material, which has attracted great interest for several decades due to its metal-semiconductor transition around 60℃ (Supporting Information Fig. S1). It has been widely used in infrared detectors48, 49. For example, the commercial VO2 infrared detector can detect a temperature variation as low as 30 mK50. To enable the on-chip direct readout of the mid-IR gas sensing signal, VO2 is deposited close to the metal layer and is separated by a Si3N4 layer to avoid shortcut as shown in

2.2 Optical design

The optical model of the gas sensor is shown in

Fig. 2. (a ) Simulated absorption spectra at different n gas for the device structure in Fig. 1(a) . The period of gratings P = 3.3 µm, the grating depth h g = 160 nm, and the grating width w g = (w 1+w 2)/2 = 3 µm. (b ) Q factor and FoM at various n gas. (c ) The electric field distribution at the resonance peak (λ = 3.3 μm) at n gas

= 1. (d ) Poynting vector at the resonance. (e ) The calculated absorption spectra as functions of wavelength and incident angle. (f ) Sensitivities of different order modes versus the incident angle.

It is important to understand the physics governing the light coupling to the high Q surface resonant mode. In such a continuous metal film coated grating structure, propagating SPR modes are supported. Therefore, the resonance wavelength of the diffractive coupled surface propagating mode can be de determined by the momentum matching conditions:

where θin is the incident angle, G=2π/P is the grating constant, k=2πngas/λ is the wave vector, and ksp is the wave vector of SPR mode. Since ultra-shallow (H < λ/20) grooves can be considered as very small perturbations to the flat metal surface, ksp can be approximately calculated using the dispersion relationship of SPR mode supported by a flat Au/dielectric interface. In addition, m is an integer representing the diffraction order while '+' and '-' signs in the right side of the equation correspond to diffracted waves of orders m > 0 (positive order) and m < 0 (negative order), respectively. In

For on-chip electrical readout, it is preferred to have a high resonant light absorption so that large electrical output signal can be realized by the temperature variation associated with light absorption. As mentioned above, the maximum absorption occurs at the critical coupling condition when the radiation loss equals the absorption loss. By finely tuning the grating depth, high absorption above 96% at the resonances is obtained as shown in

2.3 Thermal analysis

As described in the device mechanism, photothermal conversion is a key step to connect the gas induced light absorption to the on-chip electrical readout. There are two major factors for the efficient photothermal conversion in this proposed gas sensor. One is the heat capacity and the other is the heat dissipation. The smaller the heat capacity and the slower the heat dissipation, the higher temperature difference can be realized in the VO2 layer, i.e. a higher sensing performance. An SOI wafer based fabrication process is straightforward in this case by integrating the transducer in the silicon device layer and removing the backside silicon handle layer to form a membrane. As shown in

Fig. 3. (a ) Schematic of on-chip mid-IR gas sensor based on an SOI platform, where the silicon substrate in the area underneath the sensor is removed to reduce the thermal dissipation. The thickness of each layer in the Au/Si3N4/VO2/Si3N4/Si stack is 200 nm, 50 nm, 100 nm, 500 nm and 4 μm, respectively. The thickness of the oxide layer is 1 µm. P = 3.3 µm, h g = 220 nm, w g

= 3 µm. (b ) Simulated temperature distribution across the sensor with the illumination on and off when the power density of light is 3.75 W/cm2 at 3.348 μm and corresponding absorption efficiency is 58%. (c ) Temperature maximum under different wavelength illumination at the same power density and the absorption spectra of the gratings. The period number of the grating is 100. (d ) Absorption spectra for variation of different environmental RI. (e ) Absorption at 3.345 µm illumination and the associated device temperature versus the variation of different environmental RI.

As shown in

3 Results and discussion

3.1 Thermal optimization and gas enrichment

To further improve the sensitivity, optimizing thermal design and introducing gas enrichment are both potential solutions. Actually, the device structure in

Fig. 4. (a ) Schematic of on-chip mid-IR gas sensor array based on an air bridge structure. The grating region has a size of 330 µm × 50 µm. The Au/Si3N4/VO2/Si3N4 stack is shown in the inset and the thicknesses are 200 nm/50 nm/100 nm/500 nm, respectively. The stack is supported by the Si3N4/W bridges on Si substrate. (b ) Temperature and relative electrical resistance variation of the sensors versus the variation of different environment gas RI. 'PD' means the power density of the incident light. (c ) Simulated temperature distribution across the sensor with and without illumination at a wavelength of 3.348 µm with a power density of 1 W/cm2 and the absorption is 58%.

3.2 Absorptive gas sensing and on-chip spectroscopy

It is noted that only pure RI sensing is discussed above, which has no gas selection. The molecular absorption fingerprints of gases are actually very important for gas detection and identification. The common way is to choose a laser with an emission wavelength matching one absorption peak of the target gas and monitor the absorption variation. As discussion in literatures23, 33, MOF and polymer can be used to enrich the gas and thus increase the absorption. Gas enrichment technique was also used in refractive index sensing by coating MOF on metal nanoparticles57. Moreover, the greatly localized field of SPP as shown in

As shown in

Fig. 5. (a ) Absorption spectra of a similar sensor as shown in Fig. 4 with an additional MOF layer placed on the top surface in pure Ar2 and a mixture of Ar(90%)/CO2(10%). The result in a mixture of Ar(90%)/CO2(10%) ignoring the absorbance of CO2 is also shown for comparison. P = 1.99 µm, h g

= 100 nm, w g = 1.25 µm. RIs of CO2 and MOF refer to literatures57, 60. For a same membrane size (330 μm×50 μm) with the one in Fig. 4 , there are 165 gratings in this case. (b ) Simulated temperature distribution across the sensor illuminated at a wavelength of 2.71 µm with a power density of 1 W/cm2 in a mixture of Ar(90%)/CO2(10%).

Although the narrowband detector and the MOF have some selectivity of target gas, the fault alarm could still occur using the non-dispersive method if different gases with similar absorption wavelengths or adsorption coefficients are mixed. Spectroscopy is an excellent way to address this issue because each gas has unique absorption fingerprints associated with the molecular rotation and vibrational frequency, but the current commercial spectrometers are too large and expensive for on-site application and the spectral resolution (0.5 cm-1) is limited to resolve fine gas energy level. As the proposed plasmonic gas sensor has tunable absorption wavelength by simply changing the grating period, on-chip spectroscopy can be realized if a series of sensors with different absorption wavelengths are arranged into an array. Using a broadband source, each sensor detects the signal of the target gas absorption spectrum in a certain wavelength range. By combining all these signals, the whole absorption spectral information can be obtained by using the compressive sensing algorithm (

Fig. 6. Gas molecular fingerprint spectrum reconstruction with the monolithically integrated plasmonic gas sensor array Φ (λ ).

(a ) Schematic of the reconstruction process for an unknown input signal X (λ ), where the photoelectric signal Y of each sensor is recorded. (b ) The recovered spectrum (red line) and the reference spectra by simulation based on HITRAN database (black and blue lines).

As seen, a large number of sensors in an array are required to construct the spectra although the number can be further reduced by optimizing the reconstruction algorithm. It is also preferred to reduce the size of each sensor to improve the mechanical stability of the membrane structure. In our case each sensor has a sensing area of 330 μm×50 μm at a cost of absorption as shown in

4 Conclusions

In conclusion, we proposed and demonstrated numerically a novel plasmonic mid-IR gas sensor, which shows a remarkable gas absorption enhancement factor over 8000 in an ultracompact optical interaction length of only several microns. Moreover, on-chip readout and spectroscopy have been achieved by integrating optical sensing, photothermal detection and compressive sensing algorithm. In particular, the estimated spectral resolution as high as 0.01 nm is quite promising to use in gas identification with such a portable device. The unity integration idea of active and passive optical components provides a novel technique for on-chip sensing. The shallow metal grating structure in the proposed sensor also provide an excellent platform combining both localized electromagnetic field and high Q factor.

5 Acknowledgements

We are grateful for financial supports from National Key Research and Development Program of China (No. 2019YFB2203402), National Natural Science Foundation of China (Nos. 11774383, 11774099 and 11874029), Guangdong Science and Technology Program International Cooperation Program (2018A050506039), Guangdong Natural Science Founds for Distinguished Young Scholars (No. 2020B151502074), Pearl River Talent Plan Program of Guangdong (No. 2019QN01X120), Fundamental Research Funds for the Central Universities, Royal Society Newton Advanced Fellowship (No. NA140301) and Key Frontier Scientific Research Program of the Chinese Academy of Sciences (No. QYZDBSSW-JSC014).

6 Author contributions

Q. Chen and L. Wen conceived the work and proposed the design. L. Liang, L. Wen and Q. L. Zheng conducted the simulation. Q. Chen wrote the paper. All authors discussed the results and commented on the manuscript.

7 Competing interests

The authors declare no competing financial interests.

8 Supplementary information

[51] Palik E D.

[56] A Rogalski. Progress in focal plane array technologies. Prog Quant Electron, 2012, 36: 342-473.

[64] J Bao, M G Bawendi. A colloidal quantum dot spectrometer. Nature, 2015, 523: 67-70.

Article Outline

Qin Chen, Li Liang, Qilin Zheng, Yaxin Zhang, Long Wen. On-chip readout plasmonic mid-IR gas sensor[J]. Opto-Electronic Advances, 2020, 3(7): 07190040.