[1] S. Y. Chou, P. R. Krauss, P. J. Renstrom. Imprint of sub-25 nm vias and trenches in polymers. Appl. Phys. Lett., 1995, 67: 3114-3116 .

[2] J. Chen, C. Gu, H. Lin, S. Chen. Soft mold-based hot embossing process for precision imprinting of optical components on nonplanar surfaces. Opt. Express, 2015, 23: 20977-20985 .

[3] B. Berman. 3-D printing: the new industrial revolution. Bus. Horizons, 2012, 55: 155-162 .

[4] J. W. Stansbury, M. J. Idacavage. 3D printing with polymers: challenges among expanding options and opportunities. Dent. Mater., 2016, 32: 54-64 .

[5] C. Barner-Kowollik, M. Bastmeyer, E. Blasco, G. Delaittre, P. Mgller, B. Richter, M. Wegener. 3D laser micro- and nanoprinting: challenges for chemistry. Angew. Chem., 2017, 56: 15828-15845 .

[6] F. Rengier, A. Mehndiratta, H. V. Tenggkobligk, C. M. Zechmann, R. Unterhinninghofen, H. Kauczor, F. L. Giesel. 3D printing based on imaging data: review of medical applications. Int. J. Comput. Ass. Rad., 2010, 5: 335-341 .

[7] G. H. Wu, S. H. Hsu. Review: polymeric-based 3D printing for tissue engineering. J. Med. Biol. Eng., 2015, 35: 285-292 .

[8] J. Xing, M. Zheng, X. Duan. Two-photon polymerization microfabrication of hydrogels: an advanced 3D printing technology for tissue engineering and drug delivery. Chem. Soc. Rev., 2015, 44: 5031-5039 .

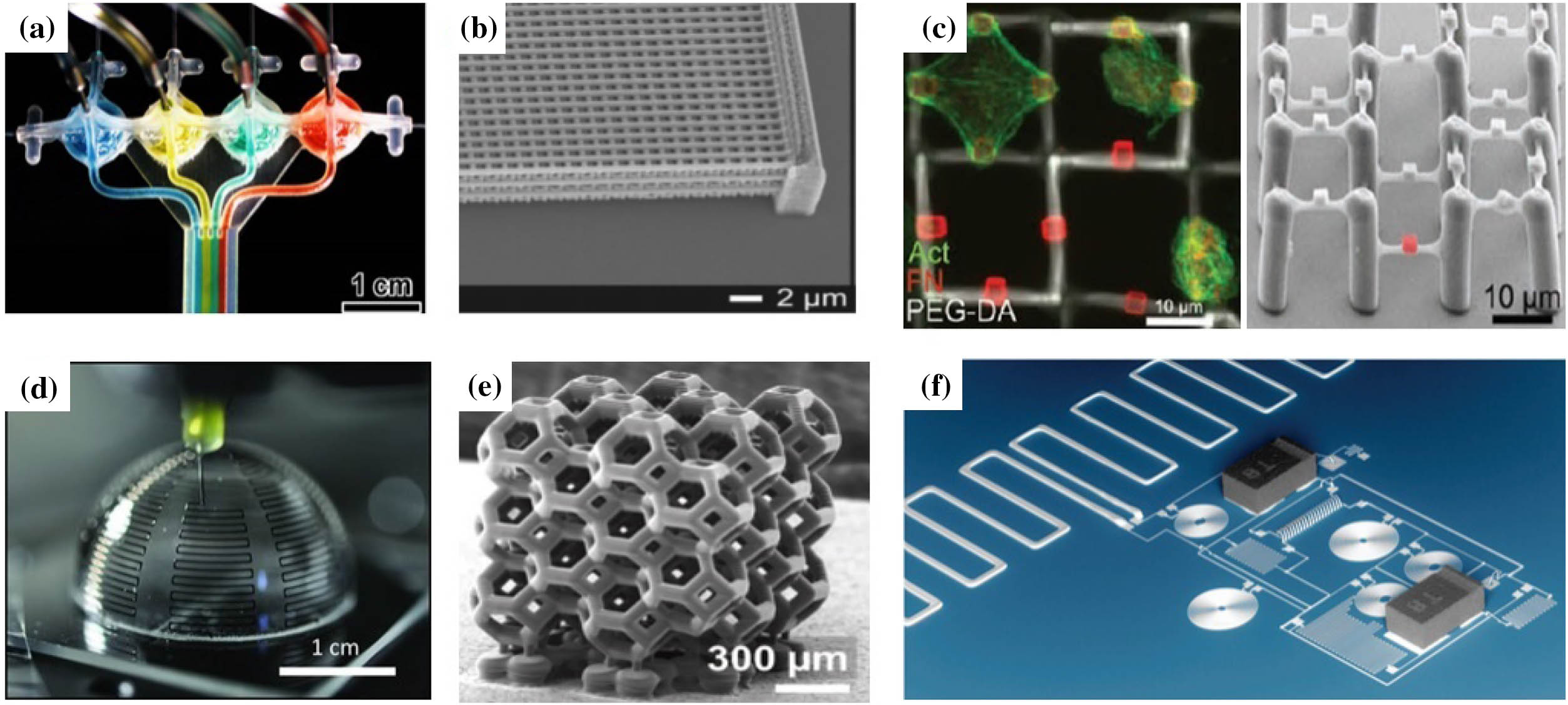

[9] R. D. Sochol, E. C. Sweet, C. C. Glick, S. Wu, C. Yang, M. A. Restaino, L. Lin. 3D printed microfluidics and microelectronics. Microelectron. Eng., 2018, 189: 52-68 .

[10] J. A. Lewis, B. Y. Ahn. Device fabrication: three-dimensional printed electronics. Nature, 2015, 518: 42-43 .

[11] Y. L. Kong, I. A. Tamargo, H. Kim, B. N. Johnson, M. K. Gupta, T. Koh, H. Chin, D. A. Steingart, B. P. Rand, M. C. Mcalpine. 3D printed quantum dot light-emitting diodes. Nano Lett., 2014, 14: 7017-7023 .

[12] T. Gissibl, S. Thiele, A. M. Herkommer, H. Giessen. Two-photon direct laser writing of ultracompact multi-lens objectives. Nat. Photonics, 2016, 10: 554-560 .

[13] B. H. Cumpston, S. P. Ananthavel, S. Barlow, D. L. Dyer, J. E. Ehrlich, L. Erskine, A. A. Heikal, S. M. Kuebler, I. Y. S. Lee, D. Mccordmaughon, J. Qin, H. Rockel, M. Rumi, X. L. Wu, S. R. Marder, J. W. Perry. Two-photon polymerization initiators for three-dimensional optical data storage and microfabrication. Nature, 1999, 398: 51-54 .

[14] P.-I. Dietrich, M. Blaicher, I. Reuter, M. Billah, T. Hoose, A. Hofmann, C. Caer, R. Dangel, B. Offrein, U. Troppenz, M. Moehrle, W. Freude, C. Koos. In situ 3D nanoprinting of free-form coupling elements for hybrid photonic integration. Nat. Photonics, 2018, 12: 241-247 .

[15] J. Luo, L. J. Gilbert, D. A. Bristow, R. G. Landers, J. T. Goldstein, A. M. Urbas, E. C. Kinzel. Additive manufacturing of glass for optical applications. Proc. SPIE, 2016, 9738: 97380Y .

[16] Y. AbouHashem, M. Dayal, S. Savanah, G. Štrkalj. The application of 3D printing in anatomy education. Med. Educ. Online, 2015, 20: 29847 .

[17] C. Gosselin, R. Duballet, P. Roux, N. Gaudilliere, J. Dirrenberger, P. Morel. Large-scale 3D printing of ultra-high-performance concrete—a new processing route for architects and builders. Mater. Design, 2016, 100: 102-109 .

[18] C. Yeh, Y. Chen. Critical success factors for adoption of 3D printing. Technol. Forecast. Soc., 2018, 132: 209-216 .

[19] Grand View Research, “3D printing market size, share & trends analysis report by material, by component, by printer type, by technology, by software, by application, by vertical, and segment forecasts, 2020 –2027 ,” Market Research Report (2020 ).

[20] M. Vaezi, H. Seitz, S. Yang. A review on 3D micro-additive manufacturing technologies. Int. J. Adv. Manuf. Technol., 2013, 67: 1721-1754 .

[21] R. D. Sochol, E. Sweet, C. C. Glick, S. Venkatesh, A. Avetisyan, K. F. Ekman, A. Raulinaitis, A. Tsai, A. Wienkers, K. Korner, K. Hanson, A. Long, B. J. Hightower, G. Slatton, D. C. Burnett, T. L. Massey, K. Iwai, L. P. Lee, K. S. J. Pister, L. Lin. 3D printed microfluidic circuitry via multijet-based additive manufacturing. Lab Chip, 2016, 16: 668-678 .

[22] S. Wong, M. Deubel, F. Pérez-Willard, S. John, G. A. Ozin, M. Wegener, G. von Freymann. Direct laser writing of three-dimensional photonic crystals with a complete photonic bandgap in chalcogenide glasses. Adv. Mater., 2006, 18: 265-269 .

[23] F. Klein, B. Richter, T. Striebel, C. M. Franz, G. von Freymann, M. Wegener, M. Bastmeyer. Two-component polymer scaffolds for controlled three-dimensional cell culture. Adv. Mater., 2011, 23: 1341-1345 .

[24] J. J. Adams, E. B. Duoss, T. F. Malkowski, M. J. Motala, B. Y. Ahn, R. G. Nuzzo, J. T. Bernhard, J. A. Lewis. Conformal printing of electrically small antennas on three-dimensional surfaces. Adv. Mater., 2011, 23: 1335-1340 .

[25] X. Zheng, H. Lee, T. H. Weisgraber, M. Shusteff, J. DeOtte, E. B. Duoss, J. D. Kuntz, M. M. Biener, Q. Ge, J. A. Jackson, S. O. Kucheyev, N. X. Fang, C. M. Spadaccini. Ultralight, ultrastiff mechanical metamaterials. Science, 2014, 344: 1373-1377 .

[26] N. Zhou, C. Liu, J. A. Lewis, D. Ham. Gigahertz electromagnetic structures via direct ink writing for radio-frequency oscillator and transmitter applications. Adv. Mater., 2017, 29: 1605198 .

[27] M. A. Jafari, W. Han, F. Mohammadi, A. Safari, S. C. Danforth, N. A. Langrana. A novel system for fused deposition of advanced multiple ceramics. Rapid Prototyping J., 2000, 6: 161-175 .

[28] T. B. F. Woodfield, J. Malda, J. de Wijn, F. Péters, J. Riesle, C. A. Van Blitterswijk. Design of porous scaffolds for cartilage tissue engineering using a three-dimensional fiber-deposition technique. Biomaterials, 2004, 25: 4149-4161 .

[29] R. J. A. Allen, R. S. Trask. An experimental demonstration of effective curved layer fused filament fabrication utilising a parallel deposition robot. Addit. Manuf., 2015, 8: 78-87 .

[30] J. Go, S. N. Schiffres, A. G. Stevens, A. JohnHart. Rate limits of additive manufacturing by fused filament fabrication and guidelines for high-throughput system design. Addit. Manuf., 2017, 16: 1-11 .

[31] K. K. B. Hon, L. Li, I. M. Hutchings. Direct writing technology-advances and developments. CIRP Ann., 2008, 57: 601-620 .

[32] G. M. Gratson, M. Xu, J. A. Lewis. Direct writing of three-dimensional webs. Nature, 2004, 428: 386 .

[33] E. B. Duoss, T. H. Weisgraber, K. Hearon, C. Zhu, W. Small, T. R. Metz, J. J. Vericella, H. D. Barth, J. D. Kuntz, R. S. Maxwell, C. M. Spadaccini, T. S. Wilson. Three-dimensional printing of elastomeric, cellular architectures with negative stiffness. Adv. Funct. Mater., 2014, 24: 4905-4913 .

[34] T. D. Ngo, A. Kashania, G. Imbalzano, K. T. Q. Nguyen, D. Hui. Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Composites Part B, 2018, 143: 172-196 .

[35] D. J. Ryu, C. Sonn, D. H. Hong, K. B. Kwon, S. J. Park, H. Y. Ban, T. Y. Kwak, D. Lim, J. H. Wang. Titanium porous coating using 3D direct energy deposition (DED) printing for cementless TKA implants: does it induce chronic inflammation?. Materials, 2020, 13: 472 .

[36] L. Hirt, A. Reiser, R. Spolenak, T. Zambelli. Additive manufacturing of metal structures at the micrometer scale. Adv. Mater., 2017, 29: 1604211 .

[37] J. D. Fowlkes, R. Winkler, B. B. Lewis, A. Fernández-Pacheco, L. Skoric, D. Sanz-Hernández, M. G. Stanford, E. Mutunga, P. D. Rack, H. Plank. High-fidelity 3D-nanoprinting via focused electron beams: computer-aided design (3BID). ACS Appl. Nano Mater., 2018, 1: 1028-1041 .

[38] J. Kechagias. An experimental investigation of the surface roughness of parts produced by LOM process. Rapid Prototyping J., 2007, 13: 17-22 .

[39] D. X. Luong, A. K. Subramanian, G. A. Lopez Silva, J. Yoon, S. Cofer, K. Yang, P. S. Owuor, T. Wang, Z. Wang, J. Lou, P. M. Ajayan, J. M. Tour. Laminated object manufacturing of 3D-printed laser-induced graphene foams. Adv. Mater., 2018, 30: 1707416 .

[40] A. Reiser, M. Linden, P. Rohner, A. Marchand, H. Galinski, A. S. Sologubenko, J. M. Wheeler, R. Zenobi, D. Poulikakos, R. Spolenak. Multi-metal electrohydrodynamic redox 3D printing at the submicron scale. Nat. Commun., 2019, 10: 1853 .

[41] J. Schneider, P. Rohner, D. Thureja, M. Schmid, P. Galliker, D. Poulikakos. Electrohydrodynamic nano drip printing of high aspect ratio metal grid transparent electrodes. Adv. Funct. Mater., 2016, 26: 833-840 .

[42] S. A. Khairallah, A. T. Anderson, A. M. Rubenchik, W. E. King. Laser powder-bed fusion additive manufacturing physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater., 2016, 108: 36-45 .

[43] Fina F. Gaisford S. Basit A. W. Powder bed fusion: the working process, current applications and opportunities ,” in 3D Printing of Pharmaceuticals , Basit A. Gaisford S. 31 of AAPS Advances in the Pharmaceutical Sciences Series (Springer , 2018 ), pp. 81 –105 .

[44] S. Maruo, O. Nakamura, S. Kawata. Three-dimensional microfabrication with two-photon-absorbed photopolymerization. Opt. Lett., 1997, 22: 132-134 .

[45] S. Kawata, H. B. Sun, T. Tanaka, K. Takada. Finer features for functional microdevices–micromachines can be created with higher resolution using two-photon absorption. Nature, 2001, 412: 697-698 .

[46] T. Gissibl, S. Thiele, A. M. Herkommer, H. Giessen. Sub-micrometre accurate free-form optics by three-dimensional printing on single-mode fibres. Nat. Commun., 2016, 7: 11763 .

[47] R. Raman, B. Bhaduri, M. Mir, A. Shkumatov, M. K. Lee, G. Popescu, H. Kong, R. Bashir. High-resolution projection microstereolithography for patterning of neovasculature. Adv. Health Mater., 2016, 5: 610-619 .

[48] D. J. Mcgregor, S. H. Tawfick, W. P. King. Mechanical properties of hexagonal lattice structures fabricated using continuous liquid interface production additive manufacturing. Addit. Manuf., 2019, 25: 10-18 .

[49] William K. Maxwell J. Larsson K. Boman M. Freeform fabrication of functional microsolenoids, electromagnets and helical springs using high pressure laser chemical vapour deposition ,” in Proceedings of the 12th IEEE International Conference on Micro Electro Mechanical Systems (MEMS) (IEEE , 1999 ), pp. 232 –237 .

[50] M. C. Wanke, O. Lehmann, K. Muller, Q. Wen, M. Stuke. Laser rapid prototyping of photonic band-gap microstructures. Science, 1997, 275: 1284-1286 .

[51] E. Saleh, P. Woolliams, B. Clarke, A. Gregory, S. Greedy, C. Smartt, R. D. Wildman, I. A. Ashcroft, R. J. M. Hague, P. Dickens, C. Tuck. 3D inkjet-printed UV-curable inks for multi-functional electromagnetic applications. Addit. Manuf., 2017, 13: 143-148 .

[52] E. B. Duoss, M. Twardowski, J. A. Lewis. Sol-gel inks for direct-write assembly of functional oxides. Adv. Mater., 2007, 19: 3485-3489 .

[53] Z. Gan, Y. Cao, R. A. Evans, M. Gu. Three-dimensional deep sub-diffraction optical beam lithography with 9 nm feature size. Nat. Commun., 2013, 4: 2061 .

[54] V. Hahn, F. Mayer, M. Thiel, M. Wegener. 3-D laser nanoprinting. Opt. Photon. News, 2019, 30: 28-35 .

[55] S. W. Hell, J. Wichmann. Breaking the diffraction resolution limit by stimulated emission: stimulated-emission-depletion fluorescence microscopy. Opt. Lett., 1994, 19: 780-782 .

[56] J. Fischer, M. Wegener. Three-dimensional optical laser lithography beyond the diffraction limit. Laser Photon. Rev., 2013, 7: 22-44 .

[57] D. L. Forman, M. C. Cole, R. R. McLeod. Radical diffusion limits to photo inhibited super resolution lithography. Phys. Chem. Chem. Phys., 2013, 15: 14862-14867 .

[58] E. Andrzejewska. Photo polymerization kinetics of multifunctional monomers. Prog. Polym. Sci., 2001, 26: 605-665 .

[59] R. F. T. Stepto, J. I. Cail, D. J. R. Taylor. Polymer networks: principles of formation, structure and properties. Polimery Warsaw, 2000, 45: 455-464 .

[60] E. Andrzejewska, M. B. Bogacki, M. Andrzejewski. Variations of rate coefficients and termination mechanism during the after-effects of a light-induced polymerization of a dimethacrylate monomer. Macromol. Theor. Simul., 2001, 10: 842-849 .

[61] S. Zhu, A. Hamielec. Kinetics of polymeric network synthesis via free-radical mechanisms-polymerization and polymer modification. Makromolekulare Chemie. Macromolecular Symposia., 1992, 63: 135-182 .

[62] George O. Principles of Polymerization (Wiley , 2004 ).

[63] X. Allonas, J. Lalevee, F. Morlet-Savary, J. P. Fouassier. Understanding the reactivity of photo initiating systems for photo polymerization. Polimery, 2006, 51: 491-498 .

[64] G. W. Sluggett, P. F. Mcgarry, I. V. Koptyug, N. J. Turro. Laser flash photolysis and time-resolved ESR study of phosphinoyl radical structure and reactivity. J. Am. Chem. Soc., 1996, 118: 7367-7372 .

[65] U. Kolczak, G. Rist, K. Dietliker, J. Wirz. Reaction mechanism of monoacyl- and bisacylphosphine oxide photoinitiators studied by 31 P-, 13 C-, and 1 H-CIDNP and ESR. J. Am. Chem. Soc., 1996, 118: 6477-6489 .

[66] Rumi M. Barlow S. Wang J. Perry J. W. Marder S. R. Two-photon absorbing materials and two-photon-induced chemistry ,” in Photoresponsive Polymers (Springer , 2008 ), pp. 1 –95 .

[67] S. Maruo, K. Ikuta. Submicron stereolithography for the production of freely movable mechanisms by using single-photon polymerization. Sens. Actuators A, 2002, 100: 70-76 .

[68] J. R. Tumbleston, D. Shirvanyants, N. Ermoshkin, R. Janusziewicz, A. R. Johnson, D. L. Kelly, K. Chen, R. K. Pinschmidt, J. P. Rolland, A. Ermoshkin, E. T. Samulski, J. M. Desimone. Continuous liquid interface production of 3D objects. Science, 2015, 347: 1349-1352 .

[69] J. Fischer, J. B. Mueller, J. Kaschke, T. J. A. Wolf, A. N. Unterreiner, M. Wegener. Three-dimensional multi-photon direct laser writing with variable repetition rate. Opt. Express, 2013, 21: 26244-26260 .

[70] M. Malinauskas, V. Purlys, M. Rutkauskas, A. Gaidukevičiūtė, R. Gadonas. Femtosecond visible light induced two-photon photopolymerization for 3D micro/nanostructuring in photoresists and photopolymers. Lith. J. Phys., 2010, 50: 201-207 .

[71] I. Sakellari, E. Kabouraki, D. Gray, V. Purlys, C. Fotakis, A. Pikulin, N. Bityurin, M. Vamvakaki, M. Farsari. Diffusion-assisted high-resolution direct femtosecond laser writing. ACS Nano, 2012, 6: 2302-2311 .

[72] J. Zhang, P. Xiao. 3D printing of photopolymers. Polym. Chem., 2018, 9: 1530-1540 .

[73] X. Fan, Y. Huang, X. Ding, N. Luo, C. Li, N. Zhao, S. Chen. Alignment-free liquid capsule pressure sensor for cardiovascular monitoring. Adv. Funct. Mater., 2018, 28: 1805045 .

[74] H. Cui, R. Hensleigh, D. Yao, D. Maurya, P. Kumar, M. G. Kang, S. Priya, X. R. Zheng. Three-dimensional printing of piezoelectric materials with designed anisotropy and directional response. Nat. Mater., 2019, 18: 234-241 .

[75] A. Marino, C. Filippeschi, V. Mattoli, B. Mazzolai, G. Ciofani. Biomimicry at the nanoscale: current research and perspectives of two-photon polymerization. Nanoscale, 2015, 7: 2841-2850 .

[76] M. T. Gale, M. Rossi, J. Pedersen, H. Schuetz. Fabrication of continuous-relief micro-optical elements by direct laser writing in photoresists. Opt. Eng., 1994, 33: 3556-3566 .

[77] A. Selimis, V. Mironov, M. Farsari. Direct laser writing: principles and materials for scaffold 3D printing. Microelectron. Eng., 2015, 132: 83-89 .

[78] M. Malinauskas, P. Danilevičius, S. Juodkazis. Three-dimensional micro-/nano-structuring via direct write polymerization with picosecond laser pulses. Opt. Express, 2011, 19: 5602-5610 .

[79] B. W. Pearre, C. Michas, J. Tsang, T. J. Gardner, T. M. Otchy. Fast micron-scale 3D printing with a resonant-scanning two-photon microscope. Addit. Manuf., 2019, 30: 100887 .

[80] K. Obata, A. Eltamer, L. Koch, U. Hinze, B. N. Chichkov. High-aspect 3D two-photon polymerization structuring with widened objective working range (WOW-2PP). Light Sci. Appl., 2013, 2: e116 .

[81] W. Chu, Y. Tan, P. Wang, J. Xu, W. Li, J. Qi, Y. Cheng. Centimeter-height 3D printing with femtosecond laser two-photon polymerization. Adv. Mater. Technol., 2018, 3: 1700396 .

[82] Y. Kuroiwa, N. Takeshima, Y. Narita, S. Tanaka, K. Hirao. Arbitrary micropatterning method in femtosecond laser micro processing using diffractive optical elements. Opt. Express, 2004, 12: 1908-1915 .

[83] T. Kondo, S. Matsuo, S. Juodkazis, V. Mizeikis, H. Misawa. Multi photon fabrication of periodic structures by multi beam interference of femtosecond pulses. Appl. Phys. Lett., 2003, 82: 2758-2760 .

[84] L. Kelemen, S. Valkai, P. Ormos. Parallel photo polymerisation with complex light patterns generated by diffractive optical elements. Opt. Express, 2007, 15: 14488-14497 .

[85] K. Obata, J. Koch, U. Hinze, B. N. Chichkov. Multi-focus two-photon polymerization technique based on individually controlled phase modulation. Opt. Express, 2010, 18: 17193-17200 .

[86] X. Chen, Y. Song, W. Zhang, M. Sulaman, S. Zhao, B. Guo, Q. Hao, L. Li. Imaging method based on the combination of microlens arrays and aperture arrays. Appl. Opt., 2018, 57: 5392-5398 .

[87] J. Kato, N. Takeyasu, Y. Adachi, H. Sun, S. Kawata. Multiple-spot parallel processing for laser micro nanofabrication. Appl. Phys. Lett., 2005, 86: 044102 .

[88] X. Dong, Z. Zhao, X. Duan. Micronanofabrication of assembled three-dimensional microstructures by designable multiple beams multiphoton processing. Appl. Phys. Lett., 2007, 91: 124103 .

[89] S. D. Gittard, A. Nguyen, K. Obata, A. Koroleva, R. J. Narayan, B. N. Chichkov. Fabrication of microscale medical devices by two-photon polymerization with multiple foci via a spatial light modulator. Biomed. Opt. Express, 2011, 2: 3167-3178 .

[90] V. Hahn, P. Kiefer, T. Frenzel, J. Qu, E. Blasco, C. Barnerkowollik, M. Wegener. Rapid assembly of small materials building blocks (voxels) into large functional 3D metamaterials. Adv. Funct. Mater., 2020, 30: 1907795 .

[91] T. Bückmann, M. Thiel, M. Kadic, R. Schittny, M. Wegener. An elasto-mechanical unfeelability cloak made of pentamode metamaterials. Nat. Commun., 2014, 5: 4130 .

[92] L. Yang, A. Eltamer, U. Hinze, J. Li, Y. Hu, W. Huang, J. Chu, B. N. Chichkov. Parallel direct laser writing of micro-optical and photonic structures using spatial light modulator. Opt. Laser Eng., 2015, 70: 26-32 .

[93] T. Baldacchini, S. Snider, R. Zadoyan. Two-photon polymerization with variable repetition rate bursts of femtosecond laser pulses. Opt. Express, 2012, 20: 29890-29899 .

[94] G. Vizsnyiczai, L. Kelemen, P. Ormos. Holographic multi-focus 3D two-photon polymerization with real-time calculated holograms. Opt. Express, 2014, 22: 24217-24223 .

[95] M. Manousidaki, D. G. Papazoglou, M. Farsari, S. Tzortzakis. 3D holographic light shaping for advanced multiphoton polymerization. Opt. Lett., 2020, 45: 85-88 .

[96] C. Gu, Y. Chang, D. Zhang, J. Cheng, S. Chen. Femtosecond laser pulse shaping at megahertz rate via a digital micromirror device. Opt. Lett., 2015, 40: 4018-4021 .

[97] J. Cheng, C. Gu, D. Zhang, D. Wang, S. Chen. Ultrafast axial scanning for two-photon microscopy via a digital micromirror device and binary holography. Opt. Lett., 2016, 41: 1451-1454 .

[98] M. Ren, J. Chen, D. Chen, S. Chen. Aberration-free 3D imaging via DMD-based two-photon microscopy and sensorless adaptive optics. Opt. Lett., 2020, 45: 2656-2659 .

[99] D. Wang, J. F. C. Loo, W. Lin, Q. Geng, E. K. S. Ngan, S. K. Kong, Y. Yam, S. Chen, H. P. Ho. Development of a sensitive DMD-based 2-D SPR sensor array using single-point detection strategy for multiple aptamer screening. Sens. Actuators B, 2020, 305: 127240 .

[100] D. Wang, C. Wen, Y. Chang, W. Lin, S. Chen. Ultrafast laser-enabled 3D metal printing: a solution to fabricate arbitrary submicron metal structures. Precis. Eng., 2018, 52: 106-111 .

[101] C. Wen, F. Feng, M. Ren, M. Somek, N. Zhao, S. Chen. Spatially-resolved random-access pump-probe microscopy based on binary holography. Opt. Lett., 2019, 44: 4083-4086 .

[102] C. Wen, M. Ren, F. Feng, W. Chen, S. Chen. Compressive sensing for fast 3-D and random-access two-photon microscopy. Opt. Lett., 2019, 44: 4343-4346 .

[103] Q. Geng, C. Gu, J. Cheng, S. Chen. Digital micromirror device-based two-photon microscopy for three-dimensional and random-access imaging. Optica, 2017, 4: 674-677 .

[104] Q. Geng, D. Wang, P. Chen, S. Chen. Ultrafast multi-focus 3-D nano-fabrication based on two-photon polymerization. Nat. Commun., 2019, 10: 2179 .

[105] A. Bertsch, S. Zissi, J. Y. Jézéquel, S. Corbel, J. C. Andre. Microstereophotolithography using a liquid crystal display as dynamic mask-generator. Microsyst. Technol., 1997, 3: 42-47 .

[106] C. Sun, N. Fang, D. M. Wu, X. Zhang. Projection micro-stereolithography using digital micro-mirror dynamic mask. Sens. Actuators A, 2005, 121: 113-120 .

[107] J. Choi, R. B. Wicker, S. Lee, K. H. Choi, C. Ha, I. Chung. Fabrication of 3D biocompatible/biodegradable micro-scaffolds using dynamic mask projection microstereolithography. J. Mater. Process. Technol., 2009, 209: 5494-5503 .

[108] H. Kim, S. K. Moon, M. Seo. Hybrid layering scanning-projection micro-stereolithography for fabrication of conical microlens array and hollow microneedle array. Microelectron. Eng., 2016, 153: 15-19 .

[109] Q. Wang, J. A. Jackson, Q. Ge, J. B. Hopkins, C. M. Spadaccini, N. X. Fang. Lightweight mechanical metamaterials with tunable negative thermal expansion. Phys. Rev. Lett., 2016, 117: 175901 .

[110] Q. Mu, L. Wang, C. K. Dunn, X. Kuang, F. Duan, Z. Zhang, H. J. Qi, T. Wang. Digital light processing 3D printing of conductive complex structures. Addit. Manuf., 2017, 18: 74-83 .

[111] X. Song, Y. Chen, T. W. Lee, S. Wu, L. Cheng. Ceramic fabrication using mask-image-projection-based stereolithography integrated with tape-casting. J. Manuf. Proc., 2015, 20: 456-464 .

[112] Y. Y. C. Choong, S. Maleksaeedi, H. Eng, P.-C. Su, J. Wei. Curing characteristics of shape memory polymers in 3D projection and laser stereolithography. Virtual Phys. Prototyp., 2017, 12: 77-84 .

[113] D. Han, C. Farino, C. Yang, T. Scott, D. Browe, W. Choi, J. W. Freeman, H. Lee. Soft robotic manipulation and locomotion with a 3D printed electroactive hydrogel. ACS Appl. Mater. Interfaces, 2018, 10: 17512-17518 .

[114] Y. Yang, Z. Chen, X. Song, B. Zhu, T. K. Hsiai, P. Wu, R. Xiong, J. Shi, Y. Chen, Q. Zhou, K. K. Shung. Three dimensional printing of high dielectric capacitor using projection based stereolithography method. Nano Energy, 2016, 22: 414-421 .

[115] D. Han, C. Yang, N. X. Fang, H. Lee. Rapid multi-material 3D printing with projection micro-stereolithography using dynamic fluidic control. Addit. Manuf., 2019, 27: 606-615 .

[116] D. A. Walker, J. L. Hedrick, C. A. Mirkin. Rapid, large-volume, thermally controlled 3D printing using a mobile liquid interface. Science, 2019, 366: 360-364 .

[117] G. Zhu, J. V. Howe, M. Durst, W. Zipfel, C. Xu. Simultaneous spatial and temporal focusing of femtosecond pulses. Opt. Express, 2005, 13: 2153-2159 .

[118] D. Oron, E. Tal, Y. Silberberg. Scanningless depth-resolved microscopy. Opt. Express, 2005, 13: 1468-1476 .

[119] J. N. Yih, Y. Y. Hu, Y. D. Sie, L. C. Cheng, C. H. Lien, S. J. Chen. Temporal focusing based multiphoton excitation microscopy via digital micromirror device. Opt. Lett., 2014, 39: 3134-3137 .

[120] Y. Meng, W. Lin, C. Li, S. Chen. Fast two-snapshot structured illumination for temporal focusing microscopy with enhanced axial resolution. Opt. Express, 2017, 25: 23109-23121 .

[121] C. Gu, D. Zhang, D. Wang, Y. Yam, C. Li, S. Chen. Parallel femtosecond laser light sheet micro-manufacturing based on temporal focusing. Precis. Eng., 2017, 50: 198-203 .

[122] Y. Li, L. Cheng, C. Chang, C. Lien, P. J. Campagnola, S. J. Chen. Fast multiphoton microfabrication of freeform polymer microstructures by spatiotemporal focusing and patterned excitation. Opt. Express, 2012, 20: 19030-19038 .

[123] S. K. Saha, D. Wang, V. H. Nguyen, Y. Chang, J. S. Oakdale, S. Chen. Scalable submicrometer additive manufacturing. Science, 2019, 366: 105-109 .

[124] S. K. Saha, S. Chen. Comment on ‘rapid assembly of small materials building blocks (voxels) into large functional 3D metamaterials’. Adv. Funct. Mater., 2020, 30: 2001060 .

[125] M. Shusteff, A. E. M. Browar, B. Kelly, J. Henriksson, T. H. Weisgraber, R. M. Panas, N. X. Fang, C. M. Spadaccini. One-step volumetric additive manufacturing of complex polymer structures. Sci. Adv., 2017, 3: 5496 .

[126] B. Kelly, I. Bhattacharya, H. Heidari, M. Shusteff, C. M. Spadaccini, H. Taylor. Volumetric additive manufacturing via tomographic reconstruction. Science, 2019, 363: 1075-1079 .

[127] D. J. Brenner, E. J. Hall. Computed tomography—an increasing source of radiation exposure. New Engl. J. Med., 2007, 357: 2277-2284 .

[128] D. Loterie, P. Delrot, C. Moser. High-resolution tomographic volumetric additive manufacturing. Nat. Commun., 2020, 11: 852 .

[129] J. S. Oakdale, R. F. Smith, J. Forien, W. L. Smith, S. Ali, L. B. B. Aji, T. M. Willey, J. Ye, A. W. V. Buuren, M. A. Worthington, S. T. Prisbrey, H. Park, P. Amendt, T. F. Baumann, J. Biener. Direct laser writing of low-density interdigitated foams for plasma drive shaping. Adv. Funct. Mater., 2017, 27: 1702425 .

[130] L. R. Meza, S. Das, J. R. Greer. Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science, 2014, 345: 1322-1326 .

[131] L. A. Shaw, S. Chizari, M. Shusteff, H. Naghsh-Nilchi, D. Di Carlo, J. B. Hopkins. Scanning two-photon continuous flow lithography for synthesis of high-resolution 3D microparticles. Opt. Express, 2018, 26: 13543-13548 .

[132] M. Malinauskas, A. Žukauskas, G. Bičkauskaitė, R. Gadonas, S. Juodkazis. Mechanisms of three-dimensional structuring of photo-polymers by tightly focussed femtosecond laser pulses. Opt. Express, 2010, 18: 10209-10221 .

[133] X. Zheng, J. R. Deotte, M. P. Alonso, G. R. Farquar, T. H. Weisgraber, S. Gemberling, H. Lee, N. X. Fang, C. M. Spadaccini. Design and optimization of a light-emitting diode projection micro-stereolithography three-dimensional manufacturing system. Rev. Sci. Instrum., 2012, 83: 125001 .

[134] M. P. D. Beer, H. L. V. D. Laan, M. A. Cole, R. J. Whelan, M. A. Burns, T. F. Scott. Rapid, continuous additive manufacturing by volumetric polymerization inhibition patterning. Sci. Adv., 2019, 5: eaau8723 .

[135] A. Ovsianikov, J. Viertl, B. N. Chichkov, M. Oubaha, B. D. Maccraith, I. Sakellari, A. Giakoumaki, D. Gray, M. Vamvakaki, M. Farsari, C. Fotakis. Ultra-low shrinkage hybrid photosensitive material for two-photon polymerization microfabrication. ACS Nano, 2008, 2: 2257-2262 .

[136] T. Buckmann, N. Stenger, M. Kadic, J. Kaschke, A. Frolich, T. Kennerknecht, C. Eberl, M. Thiel, M. Wegener. Tailored 3D mechanical metamaterials made by dip-in direct-laser-writing optical lithography. Adv. Mater., 2012, 24: 2710-2714 .

[137] R. Batchelor, T. Messer, M. Hippler, M. Wegener, C. Barnerkowollik, E. Blasco. Two in one: light as a tool for 3D printing and erasing at the microscale. Adv. Mater., 2019, 31: 1904085 .

[138] J. Fischer, M. Wegener. Three-dimensional direct laser writing inspired by stimulated-emission-depletion microscopy. Opt. Mater. Express, 2011, 1: 614-624 .

[139] R. Wollhofen, J. Katzmann, C. Hrelescu, J. Jacak, T. A. Klar. 120 nm resolution and 55 nm structure size in STED-lithography. Opt. Express, 2013, 21: 10831-10840 .

[140] J. Fischer, J. B. Mueller, A. S. Quick, J. Kaschke, C. Barnerkowollik, M. Wegener. Exploring the mechanisms in STED-enhanced direct laser writing. Adv. Opt. Mater., 2015, 3: 221-232 .

[141] J. Kaschke, M. Wegener. Gold triple-helix mid-infrared metamaterial by STED-inspired laser lithography. Opt. Lett., 2015, 40: 3986-3989 .

[142] J. Fischer, G. V. Freymann, M. Wegener. The materials challenge in diffraction-unlimited direct-laser-writing optical lithography. Adv. Mater., 2010, 22: 3578-3582 .

[143] P. Muller, R. Muller, L. Hammer, C. Barnerkowollik, M. Wegener, E. Blasco. STED-inspired laser lithography based on photoswitchable spirothiopyran moieties. Chem. Mater., 2019, 31: 1966-1972 .

[144] H. Ni, G. Yuan, L. Sun, N. Chang, D. Zhang, R. Chen, L. Jiang, H. Chen, Z. Gu, X. Zhao. Large-scale high-numerical-aperture super-oscillatory lens fabricated by direct laser writing lithography. RSC Adv., 2018, 8: 20117-20123 .

[145] L. Jonušauskas, D. Gailevičius, S. Rekštytė, T. Baldacchini, S. Juodkazis, M. Malinauskas. Mesoscale laser 3D printing. Opt. Express, 2019, 27: 15205-15221 .

[146] L. Jonušauskas, T. Baravykas, D. Andrijec, T. Gadišauskas, V. Purlys. Stitchless support-free 3D printing of free-form micromechanical structures with feature size on-demand. Sci. Rep., 2019, 9: 17533 .

[147] S. K. Saha, C. Divin, J. Cuadra, R. M. Panas. Effect of proximity of features on the damage threshold during submicron additive manufacturing via two-photon polymerization. J. Micro Nano-Manuf., 2017, 5: 031002 .

[148] D. Yang, L. Liu, Q. Gong, Y. Li. Rapid two-photon polymerization of an arbitrary 3D microstructure with 3D focal field engineering. Macromol. Rapid Commun., 2019, 40: 1900041 .

[149] M. J. Beauchamp, H. Gong, A. T. Woolley, G. P. Nordin. 3D printed microfluidic features using dose control in X, Y, and Z dimensions. Micromachines, 2018, 9: 326 .

[150] X. Wan, R. Menon. Proximity-effect correction for 3D single-photon optical lithography. Appl. Opt., 2016, 55: A1-A7 .

[151] T. Stichel, B. Hecht, S. Steenhusen, R. Houbertz, G. Sextl. Two-photon polymerization setup enables experimental mapping and correction of spherical aberrations for improved macroscopic structure fabrication. Opt. Lett., 2016, 41: 4269-4272 .

[152] Y. Fujishiro, T. Furukawa, S. Maruo. Simple autofocusing method by image processing using transmission images for large-scale two-photon lithography. Opt. Express, 2020, 28: 12342-12351 .

[153] Bauch L. Gruss S. Teipel A. Froehlich H. Method for detecting positioning errors of circuit patterns during the transfer by means of a mask into layers of a substrate of a semiconductor wafer ,” U.S. patent application 20050068515 (March 31 , 2005 ).

Download: 968次

Download: 968次