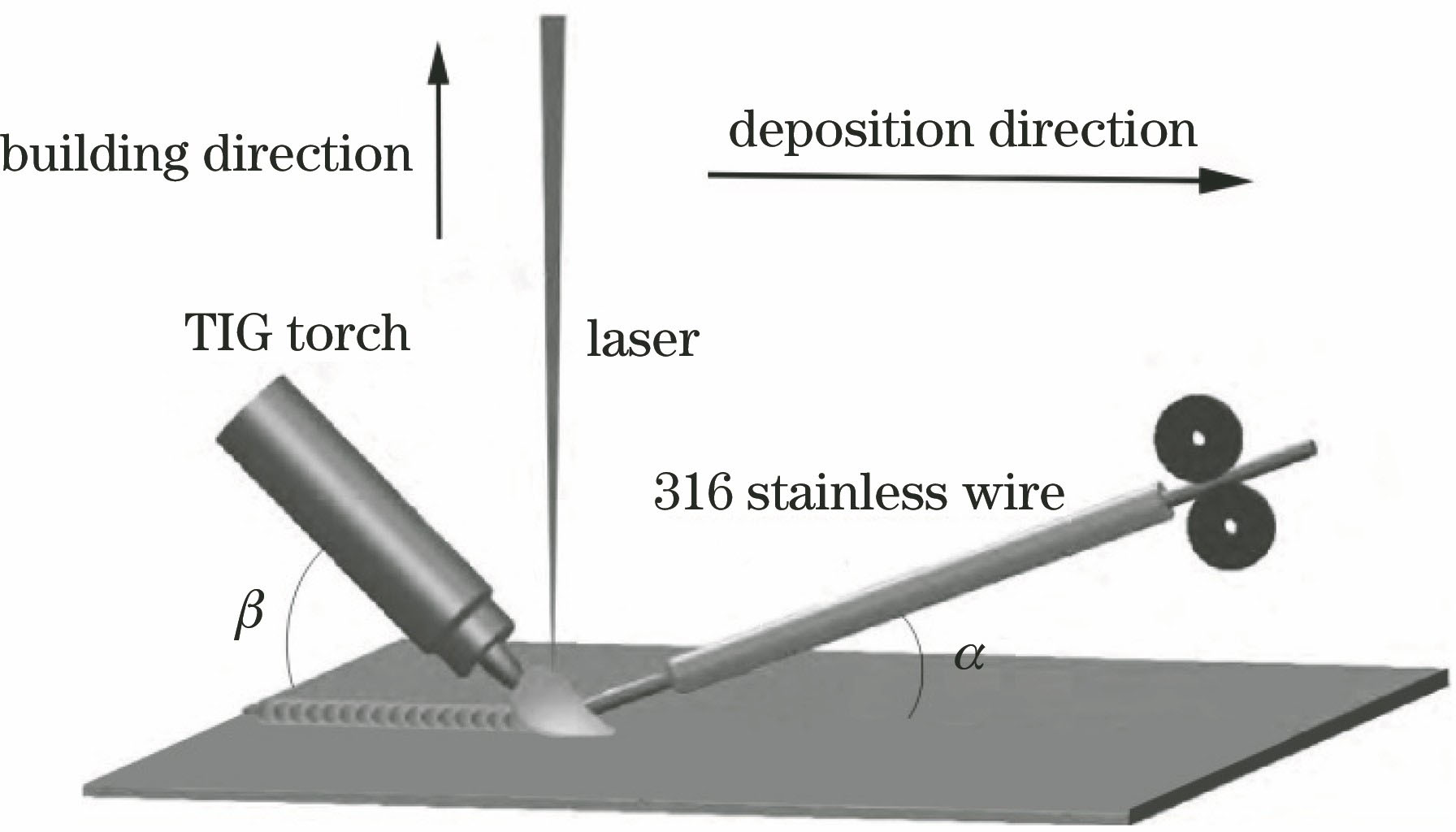

激光诱导电弧复合增材制造316不锈钢的组织和性能  下载: 1035次

下载: 1035次

李旭文, 宋刚, 张兆栋, 刘黎明. 激光诱导电弧复合增材制造316不锈钢的组织和性能[J]. 中国激光, 2019, 46(12): 1202006.

Xuwen Li, Gang Song, Zhaodong Zhang, Liming Liu. Microstructure and Properties of 316 Stainless Steel Produced by Laser-Induced Arc Hybrid Additive Manufacturing[J]. Chinese Journal of Lasers, 2019, 46(12): 1202006.

[1] 熊俊, 薛永刚, 陈辉, 等. 电弧增材制造成型技术的研究现状与展望[J]. 电焊机, 2015, 45(9): 45-50.

[2] 熊江涛, 耿海滨, 林鑫, 等. 电弧增材制造研究现状及在航空制造中应用前景[J]. 航空制造技术, 2015( 23/24): 80- 85.

Xiong JT, Geng HB, LinX, et al. Research status of wire and arc additive manufacture and its application in aeronautical manufacturing[J]. Aeronautical Manufacturing Technology, 2015( 23/24): 80- 85.

[3] Spencer D, Dickens M, Wykes M. Rapid prototyping of metal parts by three-dimensional welding[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 1998, 212(3): 175-182.

[6] Skiba T. Baufeld B, van der Biest O. Microstructure and mechanical properties of stainless steel component manufactured by shaped metal deposition[J]. ISIJ International, 2009, 49(10): 1588-1591.

[7] Skiba T. Baufeld B, van der Biest O. Shaped metal deposition of 300M steel[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2011, 225(6): 831-839.

[8] 罗怡, 朱亮, 韩静韬, 等. 电弧填丝增材制造过程熔滴射滴过渡特征及其对熔滴沉积成形的影响[J]. 机械工程学报, 2019, 55(3): 219-225.

[10] Panda S K, Padhee S, Sood A K, et al. Optimization of fused deposition modelling (FDM) process parameters using bacterial foraging technique[J]. Intelligent Information Management, 2009, 1(2): 89-97.

[11] Adeyemi A, Akinlabi E T, Mahamood R M. Powder bed based laser additive manufacturing process of stainless steel: a review[J]. Materials Today: Proceedings, 2018, 5(9): 18510-18517.

[13] 陈洪宇, 顾冬冬, 顾荣海, 等. 5CrNi4Mo模具钢选区激光熔化增材制造组织演变及力学性能研究[J]. 中国激光, 2016, 43(2): 0203003.

[14] 刘正武, 程序, 李佳, 等. 激光增材制造05Cr15Ni5Cu4Nb沉淀硬化不锈钢的热处理工艺[J]. 中国激光, 2017, 44(6): 0602010.

[16] Näsström J, Brückner F. Kaplan A F H. Measuring the effects of a laser beam on melt pool fluctuation in arc additive manufacturing[J]. Rapid Prototyping Journal, 2019, 25(3): 488-495.

[18] Wu S C, Hu Y N, Duan H, et al. On the fatigue performance of laser hybrid welded high Zn 7000 alloys for next generation railway components[J]. International Journal of Fatigue, 2016, 91: 1-10.

[19] KouS. Welding metallurgy[M]. USA: John Wiley & Sons, Inc., 2003.

[20] Francis FC. Introduction to plasma physics[M]. New York: Plenum Press, 1974.

[21] 贺立华. 焊接快速成形316L不锈钢的组织和性能研究[D]. 南昌: 南昌航空大学, 2015.

He LH. Microstructure and mechanical properties of 316L stainless steel fabricated by welding rapid forming[D]. Nanchang: Nanchang Hangkong University, 2015.

[22] Ye CQ, Peng XY, HouS, et al.Processing and properties of 316 stainless steel nuclear grade experimental component made by additive manufacturing[C]∥2018 9th International Conference on Civil Engineering, Materials and Machinery (ICCEMM 2018), July 7-8, 2018, Changchun, China.UK: Francis Academic Press, 2018.

[23] 潘春旭, 朱凤艳, 陈雁荡. 奥氏体不锈钢焊缝组织和偏析的电镜研究[J]. 武汉水运工程学院学报, 1990, 14(4): 419-424.

李旭文, 宋刚, 张兆栋, 刘黎明. 激光诱导电弧复合增材制造316不锈钢的组织和性能[J]. 中国激光, 2019, 46(12): 1202006. Xuwen Li, Gang Song, Zhaodong Zhang, Liming Liu. Microstructure and Properties of 316 Stainless Steel Produced by Laser-Induced Arc Hybrid Additive Manufacturing[J]. Chinese Journal of Lasers, 2019, 46(12): 1202006.