基于模糊控制的自适应激光功率稳定系统研究  下载: 921次

下载: 921次

Objective Laser are used in many research fields such as quantum communication, atom cooling, atom clock, and materials processing. The power stability of laser is very important, especially in the field of quantum precision measurements where it directly affects the experimental measurement accuracy. For the atom clock, the power stability of the laser affects its stability and accuracy. Therefore, it is necessary to make the active laser power stabilization system. As a general control method, the fuzzy proportional-integral-differential (PID) control has been widely used in the closed-loop control systems, such as temperature control, path planning, flight attitude adjustment, etc. A recent study investigates the laser power stabilization with the analog circuit PID, but in which the values of PID parameters need to be readjusted if it is used in different environments and the stabilized value of laser power cannot be changed during the experiments. In order to solve these problems, the fuzzy PID control scheme is proposed. We hope that our solution can reduce the stable time of the feedback loop, improve the relative intensity noise, and achieve long-term stabilization of laser power.

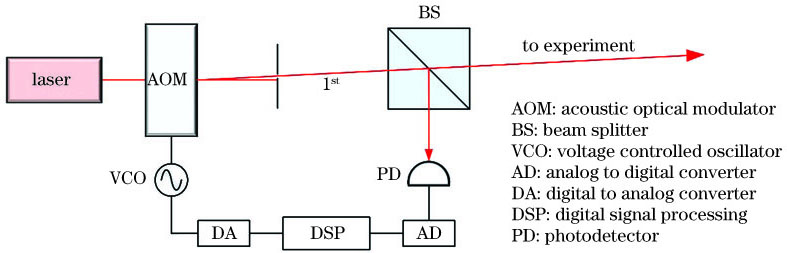

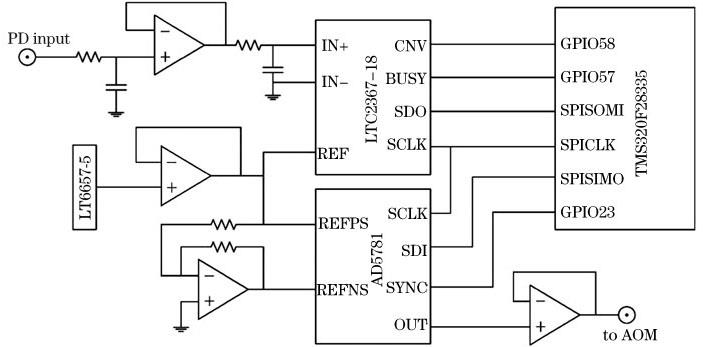

Methods There are two types of feedback loop for the laser power stabilization, one is feedback to the laser current (internal loop), and the other is feedback to an acoustic optical modulator (AOM) (external loop). Generally, the external lock loop is used because the internal loop will disturb the laser current and thus the frequency. In this paper, an embedded system of laser power stabilization based on fuzzy control is investigated. The lock loop is realized by feedback to an AOM. After passing through AOM, the laser generates diffractive light. By adjusting the diaphragm only +1 order diffraction light is allowed to pass through. After passing through the beam splitter, it is divided into two beams. One beam is detected by the photodetector, the other beam is used for experiments. The digital control circuit consists of an analog-to-digital (AD) converter, a digital-to-analog (DA) converter, and a digital signal processing chip. First of all, the laser power is detected by photodetector. Then the voltage signal is converted to a digital signal by an AD conversion. The error signal is obtained by comparing with the standard set voltage. After that the error signal and its rate of change as well as the three parameters of PID are fuzzy, and the fuzzy algorithm controller performs the calculations. The results of the parameters of PID are clarified. Finally, the amplitude modulation voltage of AOM is output through DA after the PID operation. The key to the performance of the laser power stabilization is setting the fuzzy rules. Table 1 shows the fuzzy rules adjusted according to the actual situation.

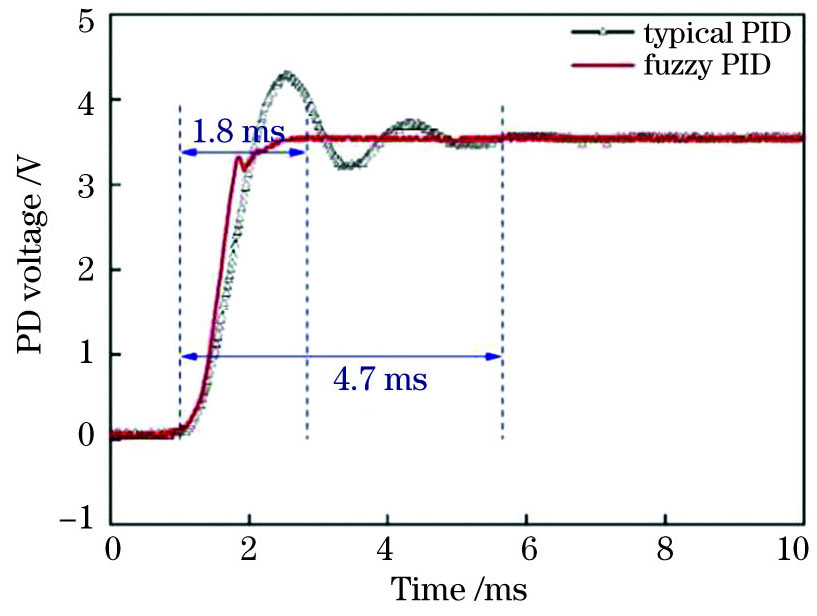

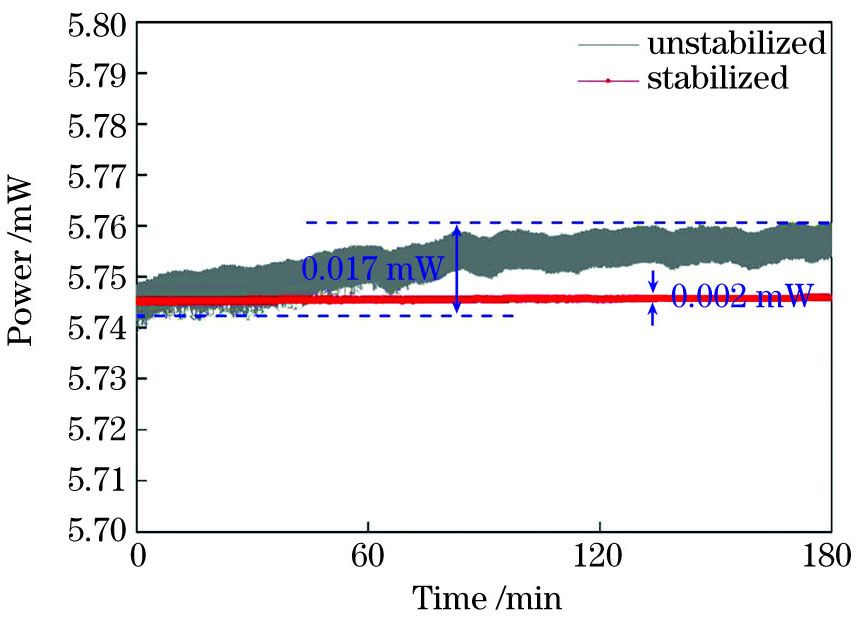

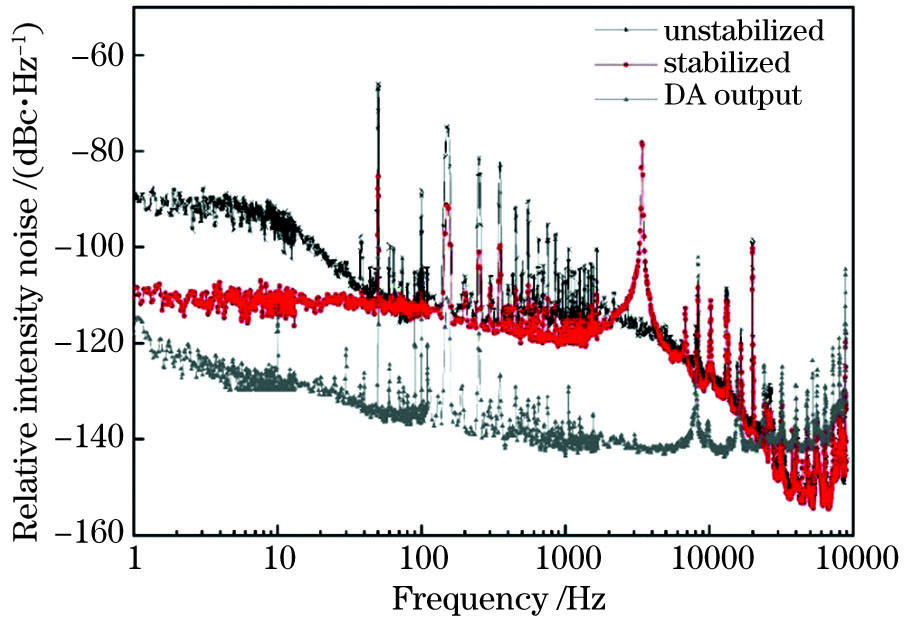

Results and Discussions The set voltage of laser power is 3.5V. It is defined that the loop stable time is the one required for the photodetector voltage that increases from 0 V to 3.5V. The stable time of laser power after fuzzy control can be obtained by monitoring the voltage of the photodetector in the feedback loop. Compared to traditional PID, the stable time is reduced from 4.7ms to 1.8ms due to the absence of overshoot (Fig. 5). The relative intensity noise of the laser power can be measured by placing the photodetector outside the loop (the beam for physical experiments). The results show that the power spectral density of relative intensity noise of the laser is depressed from -88dBc/Hz to -110dBc/Hz at 1 Hz and from -93dBc/Hz to -110dBc/Hz at 10Hz, and is lower than -110dBc/Hz over a wide frequency range, meanwhile the relative intensity noise of DA output voltage is lower than that of the laser (Fig. 6), meeting the experimental requirements. In addition, the relative fluctuation of the laser power is measured over three hours and improved from 0.29% to 0.035% after power stabilization (Fig. 7). Here, the relative fluctuation of the laser power is the ratio of the laser power fluctuation to the average.

Conclusions In this paper, a fuzzy control is applied to laser power stabilization using an embedded technique. The amplitude modulation voltage of the AOM is used to change the diffraction efficiency of the laser and thus achieve the laser power stabilization. Compared with traditional PID, after adding the fuzzy control, the feedback loop will not oscillate due to overshoot, and the stable time of the feedback loop is reduced from 4.7ms to 1.8ms. After power stabilization, the power spectral density of laser relative intensity noise is greatly improved in the low-frequency part, which is suppressed by 22 dB at 1Hz, and is lower than -110dBc/Hz over a wide frequency range. The time domain test results show that the relative fluctuation of the laser power improves from 0.29% to 0.035% within 3h. In the field of quantum precision measurement, the power stabilization technique is important for improving the measurement accuracy, such as improving the stability of atom clock and the accuracy of interferometer measurements, and because the power stabilization technique can change the stabilized laser power in real time, it is suitable for some experimental procedures that need to change the laser power in specific situations.

1 引言

激光器广泛应用于量子通信[1]、原子冷却[2-4]、原子钟[5-7]以及材料加工[8]等研究领域。激光器的功率稳定性非常重要,特别是在量子精密测量领域,其直接影响实验测量精度。对原子钟而言,激光器的功率稳定性会影响原子钟的稳定度指标[6,9]。因此,对激光器实施功率稳定非常重要。激光器功率稳定一般分为激光器内部环路反馈和外部环路反馈。内部环路反馈一般通过反馈激光器的电流实现功率稳定,但是反馈激光器电流会影响激光器的波长,因此通常采用外部环路反馈。外部环路反馈采用光学调制器实现,以声光调制器(AOM)[10]为例,通过反馈加载在AOM上的射频功率控制激光的衍射效率,进而实现功率稳定。

模糊比例-积分-微分(PID)控制作为成熟的控制方法,已广泛应用于各种闭环控制系统中,如温度控制[11-13]、路径规划[14]、飞行姿态调整[15]等。在文献[ 9]中,将模拟PID应用于激光功率稳定,通过模拟电路的方法来实现闭环控制,这种功率稳定方案在实验过程中不允许调整激光的功率,因此对于一些需要实时改变激光器光强的实验并不适用。传统的模拟PID控制环路通常在特定环境下通过调整参数来优化反馈效果,而当外部环境发生变化时,之前的参数并不能达到最优的控制效果。为此,本文采用嵌入式技术实现模糊PID控制,解决了上述问题,模糊PID能根据系统所处的不同状态,实时改变参数,并且优化了PID的超调问题,缩短了反馈环路的稳定时间。

2 实验装置及原理

表 1. KP、KI、KD模糊规则

Table 1. Fuzzy rules of KP, KI, and KD

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

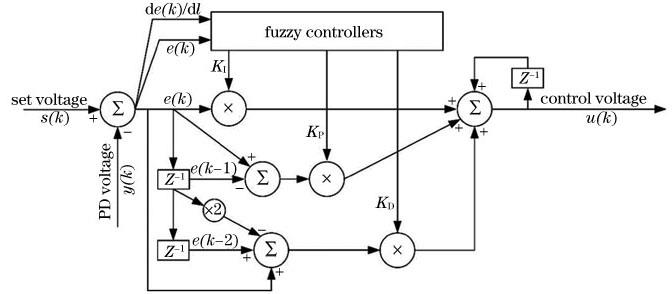

由于DSP具有高速数据运算能力,能够对激光器的功率变化进行实时反馈,因此本实验选取DSP作为主控芯片。DSP中模糊自适应PID的算法流程如

式中:k为反馈循环次数;u(k)为第k次循环的输出电压;KP、KI、KD分别为PID的比例系数、积分系数及微分系数;e

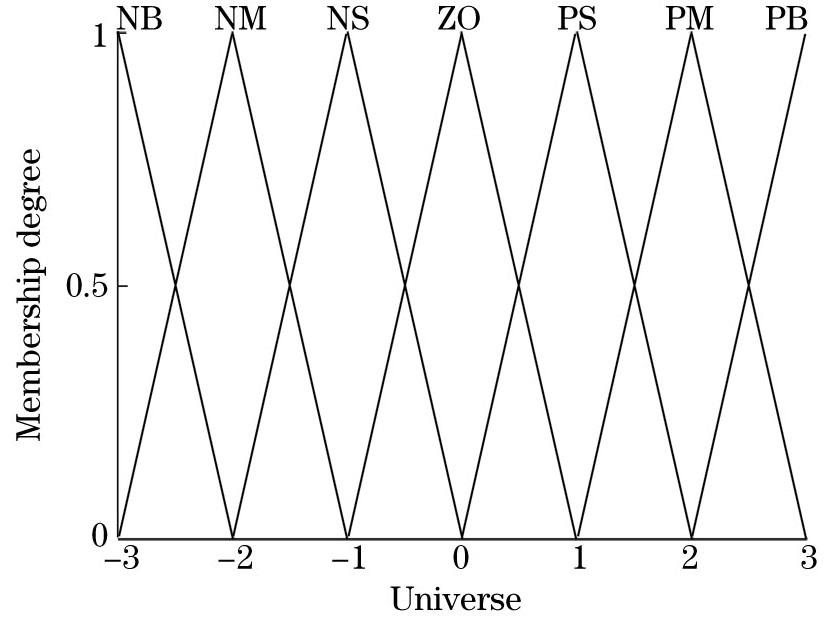

模糊算法控制器主要包括三个部分,首先对e(k)和de(k)/dt进行模糊化,然后根据模糊规则得到KP、KI、KD所对应的模糊量,最后对这三个系数的模糊量进行清晰化。本文采用三角形隶属度函数对变量进行模糊化,如

首先,将e(k)、de(k)/dt、KP、KI、KD都映射到论域{-3,-2,-1,0,1,2,3},之后根据隶属度函数得到系统当前处于各个状态的概率。NB(负强)、NM(负中)、NS(负弱)、ZO(零)、PS(正弱)、PM(正中)、PB(正强)表示变量所处状态。例如:e(k)映射到论域中所对应的值为-1.3,由

一般地,将e(k)、de(k)/dt模糊化后可分别得到系统处于四种状态的概率,再根据模糊规则得到KP、KI、KD所对应的隶属度,

式中:K为PID参数;Zi为查表所得的状态;P(i)为系统处于Zi的概率。值得注意的是,在将KP、KI、KD映射到论域时,要根据实际调试情况选取合适的因子,而在清晰化的最后,输出参数K还需要乘上这个因子才是最终输出到PID控制器中的参数。

3 硬件设计

本文采用的参考电压芯片为LT6657-5,其输出标准的5V电压作为AD芯片(LTC2367-18)的基准电压。而DA芯片(AD5781)需要正负参考电压,通过一个电压反向器得到-5V并连接至REFNS端口,如

4 实验结果与分析

激光功率稳定的电压设定为3.5V,

将光电管置于

图 6. 环路外激光相对强度噪声的功率谱密度

Fig. 6. Power spectral density of relative intensity noise of laser outside the lock loop

从时域上来看,激光功率的稳定性可以通过监测环路外功率的变化来获得,

式中:ΔP为功率变化量;

5 结论

本文采用嵌入式技术,将模糊控制应用于激光功率稳定。通过反馈AOM的调幅电压改变激光的衍射效率,进而实现激光的功率稳定。与传统的PID相比,加入模糊控制之后,反馈环路从闭合到稳定的过程中不会出现超调所导致的振荡,环路稳定所需要的时间从4.7ms缩短至1.8ms。功率稳定后,激光相对强度噪声的功率谱密度在低频部分得到了很大改善,在1Hz处被压低了22dB,并且在很宽的频率范围内,都低于-110dBc/Hz,能够满足实验要求。时域测试结果表明,激光功率在3h内的相对起伏从0.29%改善至0.035%。在量子精密测量领域,该功率稳定技术对于提高测量精度有重要意义,比如提高原子钟的稳定度指标和干涉仪的测量精度等,而且由于该功率稳定技术可以实时改变稳定后的激光功率,适用于一些实验过程中需要改变激光功率的特定场合。

[2] 王秀梅, 李琳, 孟艳玲, 等. 积分球冷原子钟冷原子数稳定的新方法[J]. 光学学报, 2017, 37(8): 0802001.

[4] Li Q X, Yan S H, Wang E L, et al. High-precision and fast-response laser power stabilization system for cold atom experiments[J]. AIP Advances, 2018, 8(9): 095221.

[5] Yu M Y, Cheng H D, Meng Y L, et al. An integrated laser system for the cold atom clock[J]. Review of Scientific Instruments, 2019, 90(5): 053203.

[7] 王新文, 项静峰, 彭向凯, 等. 基于光纤激光放大倍频的冷原子钟光源[J]. 光学学报, 2019, 39(9): 0914002.

[8] 邱莹, 张凤英, 胡腾腾, 等. 激光功率对TC4表面熔覆Ti40阻燃钛合金组织及硬度的影响[J]. 中国激光, 2019, 46(11): 1102011.

[9] TricotF, Phung DH, LoursM, et al. ( 2018-10-23)[2020-07-28]. org/abs/1808. 09777. https://arxiv.

[10] Kim D I, Rhee H G, Song J B, et al. Laser output power stabilization for direct laser writing system by using an acousto-optic modulator[J]. Review of Scientific Instruments, 2007, 78(10): 103110.

[11] 戴俊珂, 姜海明, 钟奇润, 等. 基于自整定模糊PID算法的LD温度控制系统[J]. 红外与激光工程, 2014, 43(10): 3287-3291.

Dai J K, Jiang H M, Zhong Q R, et al. LD temperature control system based on self-tuning fuzzy PID algorithm[J]. Infrared and Laser Engineering, 2014, 43(10): 3287-3291.

[12] 阮见, 邹杨, 朱海华, 等. 模糊控制在熔盐系统温度控制中的应用[J]. 核动力工程, 2018, 39(1): 106-111.

[13] Soyguder S, Karakose M, Alli H. Design and simulation of self-tuning PID-type fuzzy adaptive control for an expert HVAC system[J]. Expert Systems with Applications, 2009, 36(3): 4566-4573.

[14] 任永杰, 赵显, 郭思阳, 等. 基于wMPS和模糊控制的AGV路径规划控制[J]. 光学学报, 2019, 39(3): 0312003.

[15] 蒋林, 冷雪峰, 罗小华, 等. 基于模糊单神经元PID的四旋翼控制研究[J]. 计算机仿真, 2019, 36(10): 39-43.

Jiang L, Leng X F, Luo X H, et al. Quadrotor control based on fuzzy-single neuron PID controller[J]. Computer Simulation, 2019, 36(10): 39-43.

[16] 莫兴福, 李沙. 基于遗传算法优化的增量式PID控制器设计与实现[J]. 现代信息科技, 2020( 3): 73- 75, 80.

Mo XF, LiS. Design and implementation of incremental PID controller based on genetic algorithm optimization[J]. Modern Information Technology, 2020( 3): 73- 75, 80.

[17] 石辛民, 郝整清. 模糊控制及其MATLAB仿真[M]. 北京: 清华大学出版社, 2008: 48- 51.

Shi XM, Hao ZQ. Fuzzy control and MATLAB simulation[M]. Beijing: Tsinghua University Press, 2008: 48- 51.

欧阳鑫川, 杨博文, 万金银, 肖玲, 成华东. 基于模糊控制的自适应激光功率稳定系统研究[J]. 中国激光, 2021, 48(1): 0101003. Xinchuan Ouyang, Bowen Yang, Jinyin Wan, Ling Xiao, Huadong Cheng. Self-Adaptive Laser Power Stabilization System Based on Fuzzy Control[J]. Chinese Journal of Lasers, 2021, 48(1): 0101003.