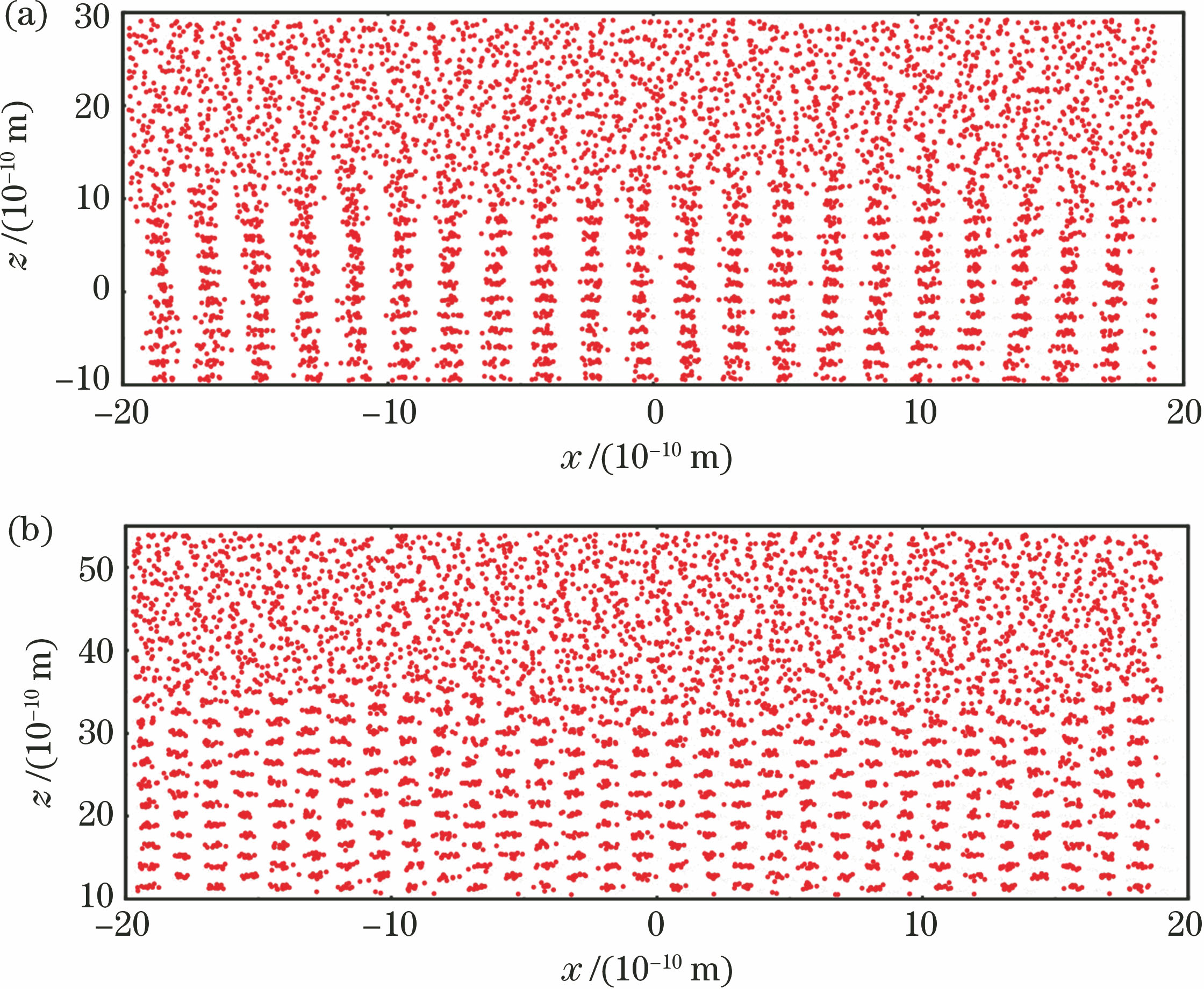

金属Ag固化过程中的空位形成研究  下载: 845次

下载: 845次

张海燕, 汪丽春. 金属Ag固化过程中的空位形成研究[J]. 激光与光电子学进展, 2019, 56(2): 021603.

Haiyan Zhang, Lichun Wang. Vacancy Formation During Solidification of Metal Ag[J]. Laser & Optoelectronics Progress, 2019, 56(2): 021603.

[1] 陈冰, 朱卫华, 陈鹏, 等. 分子动力学模拟飞秒激光烧蚀CuZr非晶合金的机理[J]. 激光与光电子学进展, 2015, 52(4): 041406.

[4] 朱成禹, 吕志伟, 何伟明, 等. 固体SBS介质与SBS相位共轭镜的全固化[J]. 激光与光电子学进展, 2006, 43(3): 65-68.

[18] Kerrache A, Horbach J, Binder K. Molecular-dynamics computer simulation of crystal growth and melting in Al50Ni50[J]. Europhysics Letters, 2008, 81(5): 58001.

[19] Qi C, Li J F, Xu B, et al. Atomistic characterization of solid-liquid interfaces in the Cu-Ni binary alloy system[J]. Computational Materials Science, 2016, 125: 72-81.

[24] FrenkelJ. Kinetic theory of liquids[M]. New York: Dover Publications, 1955.

[34] Mendelev M I, Rahman M J, Hoyt J J, et al. Molecular-dynamics study of solid-liquid interface migration in FCC metals[J]. Modelling and Simulation in Materials Science and Engineering, 2010, 18(7): 074002.

张海燕, 汪丽春. 金属Ag固化过程中的空位形成研究[J]. 激光与光电子学进展, 2019, 56(2): 021603. Haiyan Zhang, Lichun Wang. Vacancy Formation During Solidification of Metal Ag[J]. Laser & Optoelectronics Progress, 2019, 56(2): 021603.