激光熔覆制备马氏体/铁素体双相不锈钢层的力学与腐蚀性能研究  下载: 910次

下载: 910次

朱红梅, 李勇作, 张振远, 何彬, 邱长军. 激光熔覆制备马氏体/铁素体双相不锈钢层的力学与腐蚀性能研究[J]. 中国激光, 2018, 45(12): 1202012.

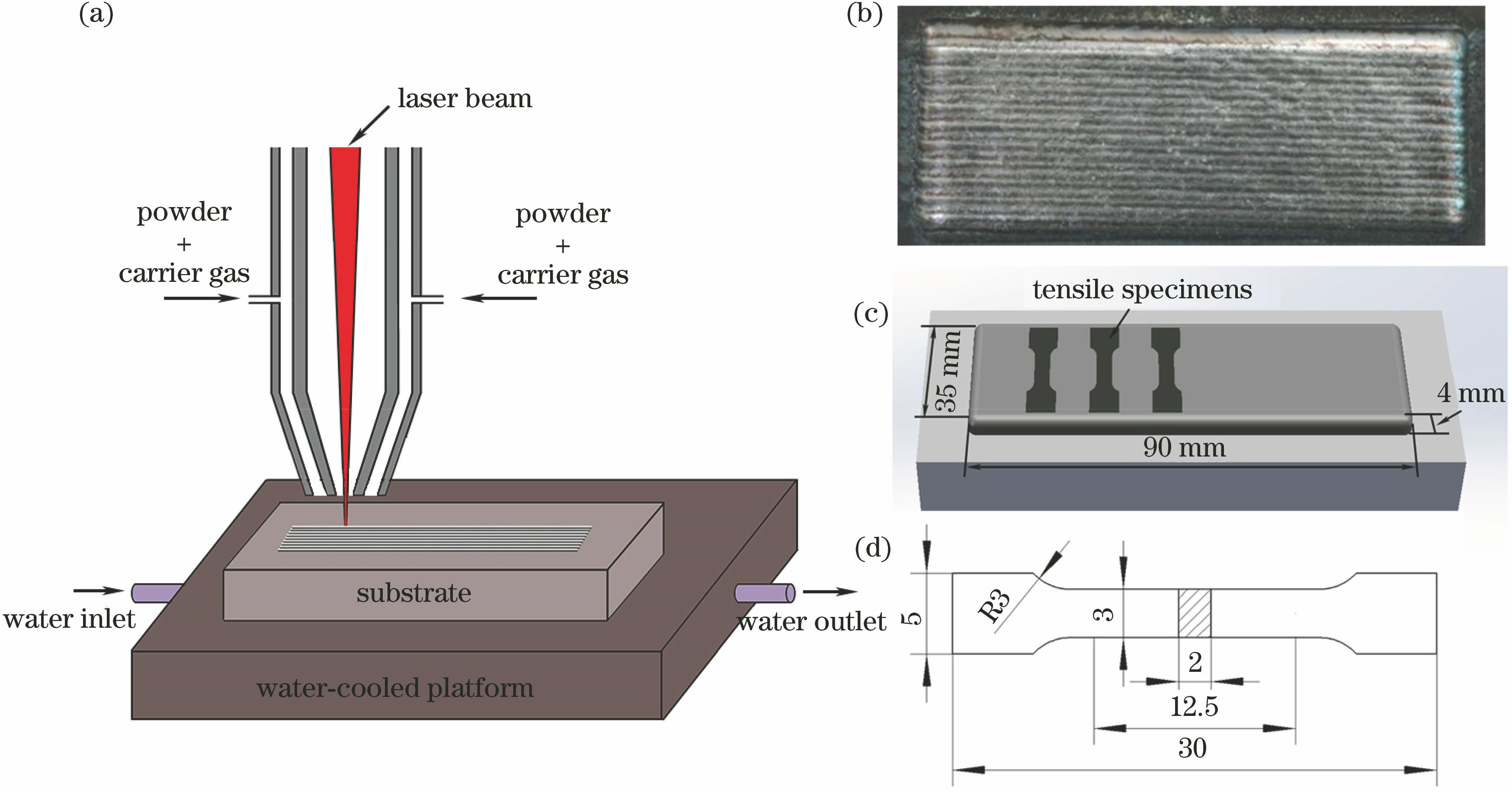

Hongmei Zhu, Yongzuo Li, Zhenyuan Zhang, Bin He, Changjun Qiu. Mechanical and Corrosion Properties of Martensite/Ferrite Duplex Stainless Steel Prepared via Laser Cladding[J]. Chinese Journal of Lasers, 2018, 45(12): 1202012.

[1] 朱红梅, 谭超林, 匡同春, 等. 低温水冷下AZ80镁合金表面激光熔覆Al63Cu27Zn10涂层的组织与性能[J]. 中国激光, 2015, 42(10): 1003005.

[2] 邓志强, 石世宏, 周斌, 等. 不等高弯曲弧形薄壁结构激光熔覆成形[J]. 中国激光, 2017, 44(9): 0902005.

[3] Wang K M, Chang B H, Chen J S, et al. Effect of molybdenum on the microstructures and properties of stainless steel coatings by laser cladding[J]. Applied Sciences, 2017, 7(10): 1065.

[20] 梁泽芬, 季根顺, 樊丁, 等. 激光改善不锈钢表面耐蚀性和抗氧化性能的研究进展[J]. 材料导报, 2009, 23(1): 67-71.

朱红梅, 李勇作, 张振远, 何彬, 邱长军. 激光熔覆制备马氏体/铁素体双相不锈钢层的力学与腐蚀性能研究[J]. 中国激光, 2018, 45(12): 1202012. Hongmei Zhu, Yongzuo Li, Zhenyuan Zhang, Bin He, Changjun Qiu. Mechanical and Corrosion Properties of Martensite/Ferrite Duplex Stainless Steel Prepared via Laser Cladding[J]. Chinese Journal of Lasers, 2018, 45(12): 1202012.