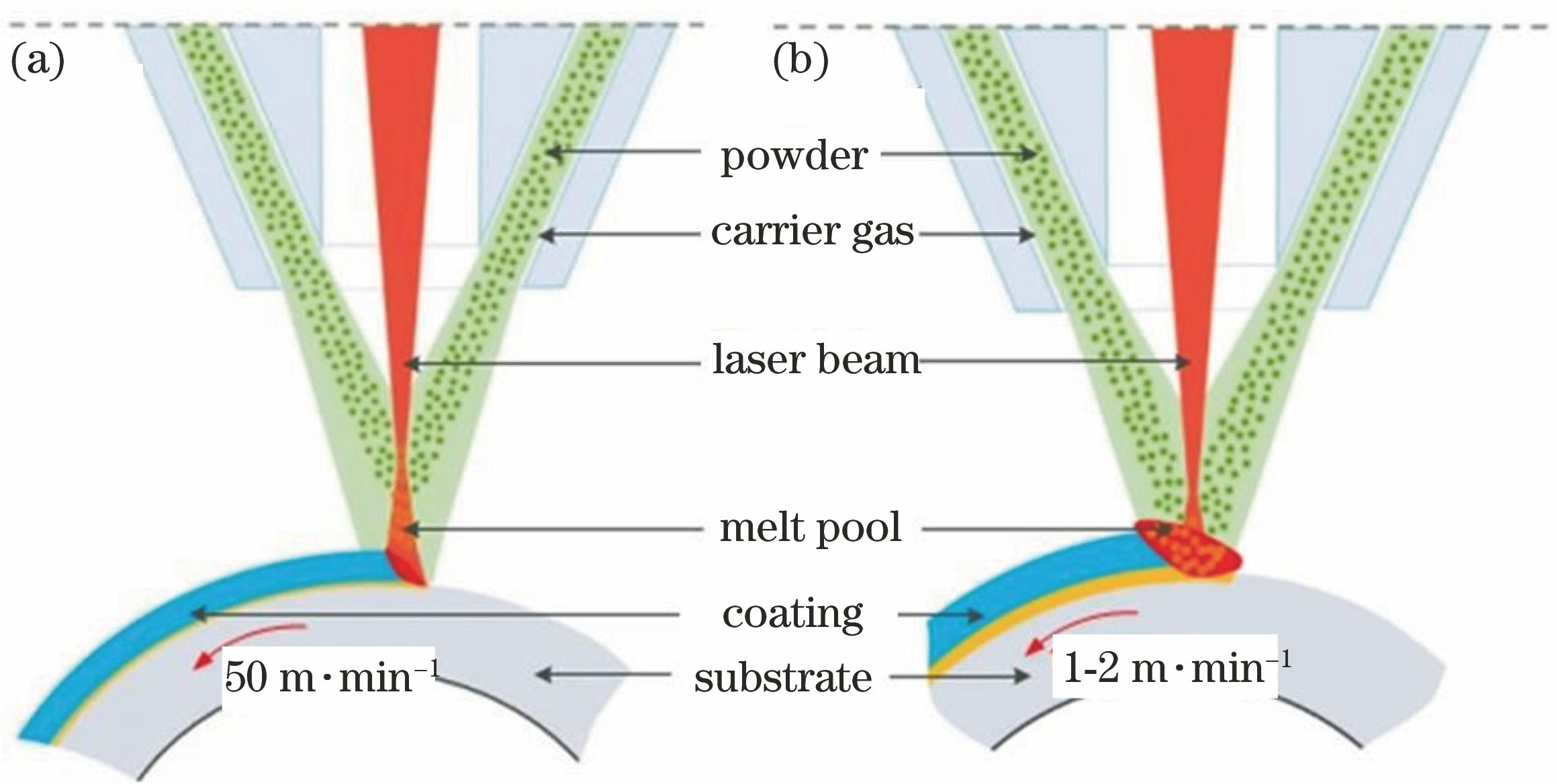

超高速激光熔覆与常规激光熔覆431不锈钢涂层微观组织和耐蚀性的对比  下载: 1724次

下载: 1724次

李俐群, 申发明, 周远东, 陶汪, 王威, 王树良. 超高速激光熔覆与常规激光熔覆431不锈钢涂层微观组织和耐蚀性的对比[J]. 中国激光, 2019, 46(10): 1002010.

Liqun Li, Faming Shen, Yuandong Zhou, Wang Tao, Wei Wang, Shuliang Wang. Comparison of Microstructure and Corrosion Resistance of 431 Stainless Steel Coatings Prepared by Extreme High-Speed Laser Cladding and Conventional Laser Cladding[J]. Chinese Journal of Lasers, 2019, 46(10): 1002010.

[1] Fouquet F, Sallamand P, Millet J P, et al. Microstructural and electrochemical characterization of laser deposited 18-10 austenitic stainless steel clad layers[J]. Journal de Physique IV, 1993, 3(C7): 991-994.

[2] Li R. Ferreira M G S, Anjos M A, et al. Localized corrosion of laser surface cladded UNS S31254 superaustenitic stainless steel on mild steel[J]. Surface and Coatings Technology, 1997, 88(1/2/3): 90-95.

[3] 任超, 李铸国, 疏达, 等. 17-4PH不锈钢表面激光熔覆Stellite6涂层组织及耐水蚀性能[J]. 中国激光, 2017, 44(4): 0402010.

[4] 朱红梅, 李勇作, 张振远, 等. 激光熔覆制备马氏体/铁素体双相不锈钢层的力学与腐蚀性能研究[J]. 中国激光, 2018, 45(12): 1202012.

[5] 叶四友, 刘建永, 杨伟. 激光熔覆316L不锈钢涂层组织和性能的研究[J]. 表面技术, 2018, 47(3): 48-53.

[6] 张美美, 刘斌, 白培康. 液压支架管激光熔覆316L不锈钢涂层组织与性能研究[J]. 测试科学与仪器, 2017, 8(2): 154-161.

[7] 袁庆龙, 冯旭东, 曹晶晶, 等. 激光熔覆技术研究进展[J]. 材料导报, 2010, 24(3): 112-116.

[8] KelbassaI,[\s]{1}GasserA,[\s]{1}MeinersW,[\s]{1}et[\s]{1}al.[\s]{1}High[\s]{1}speed[\s]{1}LAM[M][\s]{1}∥Hinduja[\s]{1}S,[\s]{1}Li[\s]{1}L.[\s]{1}Laser[\s]{1}technology:[\s]{1}additive[\s]{1}manufacturing.[\s]{1}London:[\s]{1}Springer,[\s]{1}2012:[\s]{1}381-[\s]{1}385.[\s]{1}

[11] 达则晓丽, 朱彦彦, 李铸国. 激光功率对激光熔覆Fe-Co-B-Si-Nb涂层组织和性能的影响[J]. 中国表面工程, 2012, 25(3): 52-56.

[14] 何骅波, 杨梦梦, 黄晓波, 等. 螺杆钢表面不同激光熔覆层的耐磨与耐腐蚀性能[J]. 机械工程材料, 2017, 41(10): 11-14, 19.

[15] 李泽邦.[\s]{1}Ni基复合粉末激光熔覆层组织与性能的研究[D].[\s]{1}济南:[\s]{1}山东大学,[\s]{1}2013.[\s]{1}

Li[\s]{1}ZB.[\s]{1}Study[\s]{1}on[\s]{1}microstructure[\s]{1}and[\s]{1}properties[\s]{1}of[\s]{1}Ni-based[\s]{1}composite[\s]{1}laser[\s]{1}cladding[\s]{1}layers[D].[\s]{1}Jinan:[\s]{1}Shandong[\s]{1}University,[\s]{1}2013.[\s]{1}

[17] 郭振, 温永红, 胡水平, 等. 针状铁素体钢的组织类型及对性能的影响[J]. 材料开发与应用, 2007, 22(6): 5-8.

[18] 张郁彬, 苏长伟, 张长科, 等. 镍铁合金的微观结构及其在3.5%氯化钠溶液中的腐蚀行为[J]. 电镀与涂饰, 2009, 28(12): 1-4, 17.

Zhang Y B, Su C W, Zhang C K, et al. Microstructure of Ni-Fe alloy and its corrosion behavior in 3.5% NaCl solution[J]. Electroplating & Finishing, 2009, 28(12): 1-4, 17.

[19] 于有生, 倪火炬, 温家伶. 铁基合金激光熔覆的研究[J]. 中国表面工程, 2004, 17(4): 24-27, 31.

[20] 邱星武.[\s]{1}激光熔覆制备AlCoCrCuFeNiTi系高熵合金涂层工艺及其组织性能研究[D].[\s]{1}西安:[\s]{1}西安理工大学,[\s]{1}2014.[\s]{1}

Qiu[\s]{1}XW.[\s]{1}Preparation[\s]{1}technology[\s]{1}and[\s]{1}microstructure[\s]{1}&[\s]{1}properties[\s]{1}of[\s]{1}AlCoCrCuFeNiTi[\s]{1}high-entropy[\s]{1}alloy[\s]{1}coatings[\s]{1}by[\s]{1}laser[\s]{1}cladding[D].[\s]{1}Xi'an:[\s]{1}Xi'an[\s]{1}University[\s]{1}ofTechnology,[\s]{1}2014.[\s]{1}

[21] 华小珍, 刘华英, 唐永进, 等. Mg对SiCp/Al复合材料腐蚀行为的影响[J]. 腐蚀科学与防护技术, 2011, 23(1): 13-17.

[22] 张俊旺, 王文先, 黄延平, 等. 奥氏体不锈钢焊缝金属的电化学腐蚀性能[J]. 焊接学报, 2007, 28(2): 103-107.

[23] 伍光凤.[\s]{1}BHW35钢热丝TIG堆焊接头组织及性能研究[J].[\s]{1}焊接,[\s]{1}2013([\s]{1}11):[\s]{1}23-[\s]{1}27.[\s]{1}

Wu[\s]{1}GF.[\s]{1}Microstructure[\s]{1}and[\s]{1}properties[\s]{1}of[\s]{1}surfacing[\s]{1}welded[\s]{1}joint[\s]{1}by[\s]{1}hot[\s]{1}tire[\s]{1}tungsten[\s]{1}inert-gas[\s]{1}welding[\s]{1}process[J].[\s]{1}Welding[\s]{1}&[\s]{1}Joining,[\s]{1}2013([\s]{1}11):[\s]{1}23-[\s]{1}27.[\s]{1}

[24] 赵方方, 孙会来, 孙宽. 45钢表面激光熔覆316L涂层显微组织与性能[J]. 激光与红外, 2007, 37(8): 712-714.

[25] 冯旭东.[\s]{1}低碳钢表面激光熔覆镍基涂层组织及耐蚀性研究[D].[\s]{1}焦作:[\s]{1}河南理工大学,[\s]{1}2011.[\s]{1}

Feng[\s]{1}XD.[\s]{1}Research[\s]{1}on[\s]{1}the[\s]{1}microstructure[\s]{1}and[\s]{1}corrosion[\s]{1}resistance[\s]{1}of[\s]{1}Ni-based[\s]{1}alloy[\s]{1}coatings[\s]{1}by[\s]{1}laser[\s]{1}cladding[\s]{1}on[\s]{1}the[\s]{1}soft[\s]{1}steel[D].[\s]{1}Jiaozuo:[\s]{1}Henan[\s]{1}Polytechnic[\s]{1}University,[\s]{1}2011.[\s]{1}

[26] 吴向清, 胡慧玲, 谢发勤, 等. 等离子喷涂镍基合金涂层的组织与耐蚀性[J]. 中国表面工程, 2011, 24(5): 13-17.

李俐群, 申发明, 周远东, 陶汪, 王威, 王树良. 超高速激光熔覆与常规激光熔覆431不锈钢涂层微观组织和耐蚀性的对比[J]. 中国激光, 2019, 46(10): 1002010. Liqun Li, Faming Shen, Yuandong Zhou, Wang Tao, Wei Wang, Shuliang Wang. Comparison of Microstructure and Corrosion Resistance of 431 Stainless Steel Coatings Prepared by Extreme High-Speed Laser Cladding and Conventional Laser Cladding[J]. Chinese Journal of Lasers, 2019, 46(10): 1002010.