激光熔覆W-Cu复合材料的组织形貌与工艺参数的相关性  下载: 791次

下载: 791次

顾赛男, 王广原, 秦渊, 杨森. 激光熔覆W-Cu复合材料的组织形貌与工艺参数的相关性[J]. 中国激光, 2018, 45(4): 0402005.

Gu Sainan, Wang Guangyuan, Qin Yuan, Yang Sen. Correlation between Process Parameters and Microstructure Morphologies of W-Cu Composites Fabricated by Laser Cladding[J]. Chinese Journal of Lasers, 2018, 45(4): 0402005.

[3] 周武平, 吕大铭. 钨铜材料应用和生产的发展现状[J]. 粉末冶金材料科学与工程, 2005, 10(1): 21-25.

[7] 范莉, 李业建. W-Cu复合材料的应用及制造技术[J]. 电工材料, 2013( 3): 25- 31.

FanL, Li YJ. Application and manufacturing technology of W-Cu composite material[J]. Electrical Engineering Materials, 2013( 3): 25- 31.

[8] 黄卫东. 激光立体成形——高性能致密金属零件的快速自由成形[M]. 西安: 西北工业大学出版社, 2007: 5- 10.

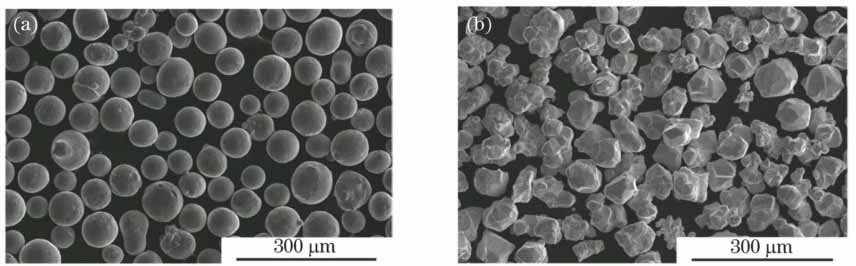

[15] 严深平, 张安峰, 李涤尘, 等. 粉末混合均匀性及W粉形态对激光直接成形W-Cu复合材料成形质量的影响[J]. 中国激光, 2017, 44(6): 0602001.

[16] 闫岸如, 杨恬恬, 王燕灵, 等. 钨粉粒度和形状对选区激光熔化W-xCu成形与显微组织的影响[J]. 中国激光, 2016, 43(2): 0203007.

[17] 吕大铭. 钨铜复合材料研究的新进展[J]. 中国钨业, 2000, 15(6): 27-31.

[19] 严铄. 纯铜表面张力的温度系数[J]. 金属学报, 1965, 8(2): 251-258.

[20] TakamichiI, Roderick I L G. The physical properties of liquid metals[M]. New York: Oxford University Press, 1993.

[21] 强文江, 吴承建. 金属材料学(第3版)[M]. 北京: 冶金工业出版社, 2016: 14.

Qiang WJ, Wu CJ. Metal material science (3th)[M]. Beijing: Metallurgical Industry Press, 2016: 14.

[22] 高海燕. 高强高导形变Cu-Fe-Ag原位复合材料制备技术基础[D]. 上海: 上海交通大学, 2007.

Gao HY. Study on high-strength and high conductivity deformation processed Cu-Fe-Ag in situ composites[D]. Shanghai: Shanghai Jiao Tong University, 2007.

顾赛男, 王广原, 秦渊, 杨森. 激光熔覆W-Cu复合材料的组织形貌与工艺参数的相关性[J]. 中国激光, 2018, 45(4): 0402005. Gu Sainan, Wang Guangyuan, Qin Yuan, Yang Sen. Correlation between Process Parameters and Microstructure Morphologies of W-Cu Composites Fabricated by Laser Cladding[J]. Chinese Journal of Lasers, 2018, 45(4): 0402005.