选区激光熔化激光功率对316L不锈钢熔池形貌及残余应力的影响  下载: 1473次

下载: 1473次

边培莹, 尹恩怀. 选区激光熔化激光功率对316L不锈钢熔池形貌及残余应力的影响[J]. 激光与光电子学进展, 2020, 57(1): 011403.

Peiying Bian, Enhuai Yin. Effect of Laser Power for Metal Selective Laser Melting on Morphology of 316L Stainless Steel Molten Pool and Residual Stress[J]. Laser & Optoelectronics Progress, 2020, 57(1): 011403.

[1] 杨永强, 陈杰, 宋长辉, 等. 金属零件激光选区熔化技术的现状及进展[J]. 激光与光电子学进展, 2018, 55(1): 011401.

[2] 刘萌. 3D打印SLM技术在机械自动化加工中的应用研究[J]. 数字技术与应用, 2015( 4): 107.

LiuM. Research on the application of 3D printing SLM technology in automatic machining[J]. Digital Technology and Application, 2015( 4): 107.

[3] 杨强, 鲁中良, 黄福享, 等. 激光增材制造技术的研究现状及发展趋势[J]. 航空制造技术, 2016( 12): 26- 31.

YangQ, Lu ZL, Huang FX, et al. Research on status and development trend of laser additive manufacturing[J]. Aeronautical Manufacturing Technology, 2016( 12): 26- 31.

[4] Sun Z J, Tan X P, Tor S B, et al. Selective laser melting of stainless steel 316L with low porosity and high build rates[J]. Materials & Design, 2016, 104: 197-204.

[5] 张凯, 刘婷婷, 张长东, 等. 基于熔池数据分析的激光选区熔化成形件翘曲变形行为研究[J]. 中国激光, 2015, 42(9): 0903007.

[6] Liu J, Yu H, Zhou T, et al. Effect of double quenching and tempering heat treatment on the microstructure and mechanical properties of a novel 5Cr steel processed by electro-slag casting[J]. Materials Science and Engineering: A, 2014, 619: 212-220.

[7] Paul R, Anand S, Gerner F. Effect of thermal deformation on part errors in metal powder based additive manufacturing processes[J]. Journal of Manufacturing Science and Engineering, 2014, 136(3): 031009.

[8] 朱小刚, 孙靖, 王联凤, 等. 激光选区熔化成形铝合金的组织、性能与倾斜面成形质量[J]. 机械工程材料, 2017, 41(2): 77-80.

Zhu X G, Sun J, Wang L F, et al. Microstructure, properties and inclined plane forming quality of aluminum alloy by selective laser melting[J]. Materials for Mechanical Engineering, 2017, 41(2): 77-80.

[9] Kamath C, El-Dasher B, Gallegos G F, et al. Density of additively-manufactured, 316L SS parts using laser powder-bed fusion at powers up to 400 W[J]. The International Journal of Advanced Manufacturing Technology, 2014, 74: 65-78.

[10] 陈光霞, 王泽敏, 关凯, 等. 工艺参数对SLM激光快速成型件表面粗糙度的影响[J]. 制造技术与机床, 2009( 12): 86- 89.

Chen GX, Wang ZM, GuanK, et al. Effects of parameters on surface roughness of samples by selective laser melting[J]. Manufacturing Technology & Machine Tool, 2009( 12): 86- 89.

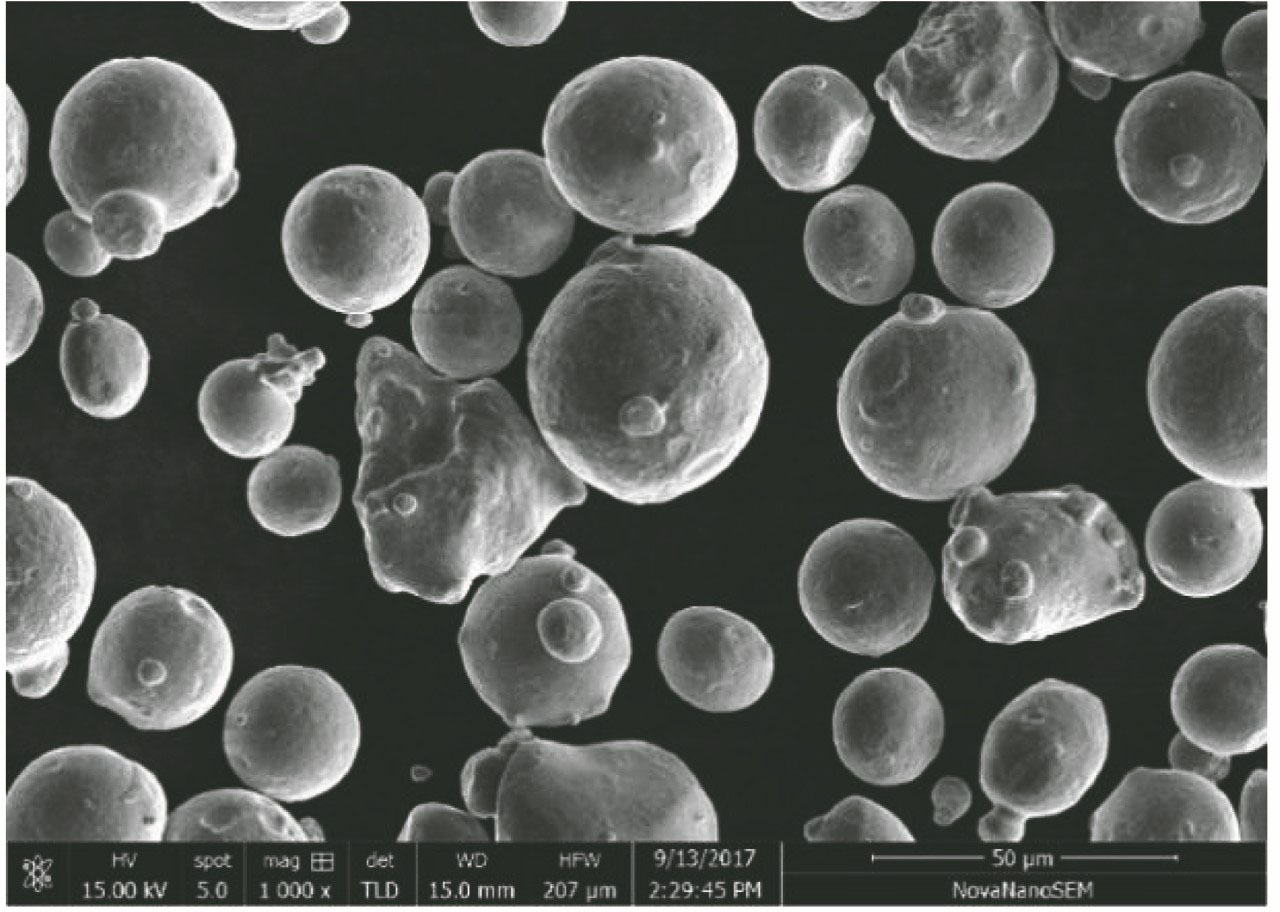

[11] 王黎, 魏青松, 贺文婷, 等. 粉末特性与工艺参数对SLM成形的影响[J]. 华中科技大学学报(自然科学版), 2012, 40(6): 20-23.

Wang L, Wei Q S, He W T, et al. Influence of powder characteristic and process parameters on SLM formability[J]. Journal of Huazhong University of Science and Technology(Natural Science Edition), 2012, 40(6): 20-23.

[12] 王沛, 黄正华, 戚文军, 等. 基于SLM技术的3D打印工艺参数对316不锈钢组织缺陷的影响[J]. 机械制造文摘-焊接分册, 2016( 2): 2- 7.

WangP, Huang ZH, Qi WJ, et al. Effect of the 3D printing process parameters based on SLM technology on the structural defect of 316 stainless steel[J]. Welding Digest of Machinery Manufacturing, 2016( 2): 2- 7.

[13] 闫程程, 杨立军, 代文豪, 等. 工艺参数对激光选区熔化316L不锈钢表面质量的影响[J]. 热加工工艺, 2017, 46(20): 170-174.

Yan C C, Yang L J, Dai W H, et al. Effect of process parameters on surface quality of laser selective melting 316L stainless steel[J]. Hot Working Technology, 2017, 46(20): 170-174.

[14] 黄建国, 余欢, 徐志锋, 等. 基于SLM的工艺参数对TC4合金成形件性能的影响[J]. 特种铸造及有色合金, 2018, 38(4): 375-379.

Huang J G, Yu H, Xu Z F, et al. Effects of processing parameters on performance of TC4 alloy samples by selective laser melting[J]. Special Casting & Nonferrous Alloys, 2018, 38(4): 375-379.

[15] Wu A S, Brown D W, Kumar M, et al. An experimental investigation into additive manufacturing-induced residual stresses in 316L stainless steel[J]. Metallurgical and Materials Transactions A, 2014, 45(13): 6260-6270.

[16] Liu Y, Yang Y Q, Wang D. A study on the residual stress during selective laser melting (SLM) of metallic powder[J]. The International Journal of Advanced Manufacturing Technology, 2016, 87: 647-656.

[17] Yan J J, Zheng D L, Li H X, et al. Selective laser melting of H13: microstructure and residual stress[J]. Journal of Materials Science, 2017, 52(20): 12476-12485.

[19] Vastola G, Zhang G, Pei Q X, et al. Controlling of residual stress in additive manufacturing of Ti6Al4V by finite element modeling[J]. Additive Manufacturing, 2016, 12: 231-239.

[20] Somashekara M A, Naveenkumar M, Kumar A, et al. Investigations into effect of weld-deposition pattern on residual stress evolution for metallic additive manufacturing[J]. The International Journal of Advanced Manufacturing Technology, 2017, 90: 2009-2025.

[21] Mercelis P, Kruth J P. Residual stresses in selective laser sintering and selective laser melting[J]. Rapid Prototyping Journal, 2006, 12(5): 254-265.

[22] Hussein A, Hao L, Yan C Z, et al. Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting[J]. Materials & Design (1980-2015), 2013, 52: 638-647.

[23] 姜传海, 杨传铮. 内应力衍射分析[M]. 北京: 科学出版社, 2013.

Jiang CH, Yang CZ. Internal stress diffraction analysis[M]. Beijing: Science Press, 2013.

[24] 边培莹. 热处理工艺对316L不锈钢粉末激光选区熔化成形的残余应力及组织的影响[J]. 材料热处理学报, 2019, 40(04): 90-97.

Bian P Y. Effect of heat treatment on residual stress and microstructure of 316L stainless steel powder formed by selective laser melting[J]. Transactions of Materials and Heat Treatment, 2019, 40(04): 90-97.

边培莹, 尹恩怀. 选区激光熔化激光功率对316L不锈钢熔池形貌及残余应力的影响[J]. 激光与光电子学进展, 2020, 57(1): 011403. Peiying Bian, Enhuai Yin. Effect of Laser Power for Metal Selective Laser Melting on Morphology of 316L Stainless Steel Molten Pool and Residual Stress[J]. Laser & Optoelectronics Progress, 2020, 57(1): 011403.