中国激光, 2020, 47 (9): 0902001, 网络出版: 2020-09-16

铌微合金化对光纤激光-CMT复合焊接A7204P-T4 铝合金接头组织和力学性能的影响  下载: 767次

下载: 767次

Effects of Nb Micro-Alloying on Microstructure and Mechanical Properties of A7204P-T4 Aluminum Alloy Joint by Fiber Laser-CMT Hybrid Welding

激光技术 激光-CMT复合焊接 A7204P-T4铝合金 铌微合金化 显微组织 力学性能 laser technique laser-cold metal transition hybrid welding A7204P-T4 aluminum alloy niobium micro-alloying microstructures mechanical properties

摘要

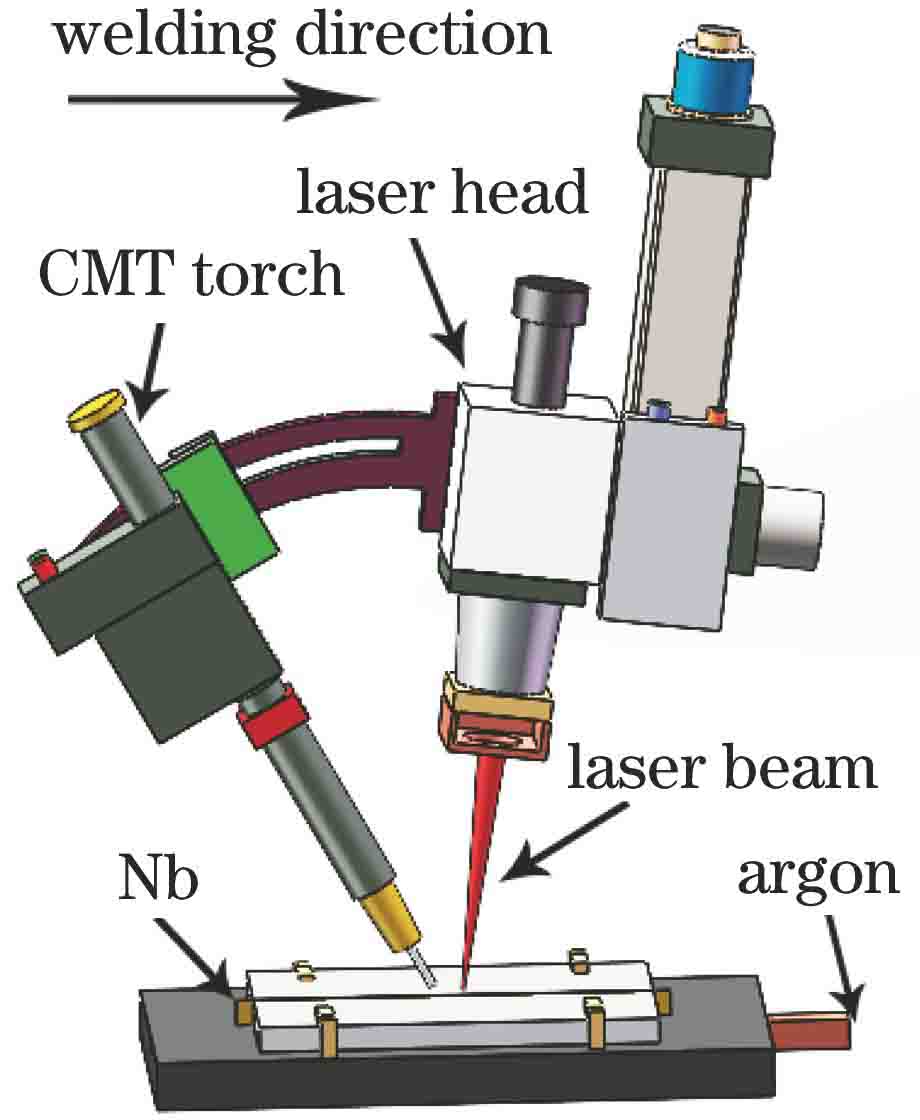

采用光纤激光-冷金属过渡电弧(CMT)复合焊接工艺对6 mm厚A7204P-T4铝合金进行对接焊接,焊前在对接界面处预置不同尺寸的铌箔(焊缝中铌的质量分数为0.74%和1.36%),采用优化的焊接参数得到了成形良好的焊接接头。研究了铌含量对复合焊接接头微观组织和力学性能的影响,并分析了焊接接头的拉伸断裂机理和断口形貌。试验结果表明:未添加铌的焊缝组织主要由细晶区、柱状晶区和等轴树枝晶区组成;加入铌箔后,铌溶质偏析和含铌析出相的异相形核使得焊缝晶粒明显细化,柱状晶与树枝晶组织基本消失;加入质量分数为0.74%的铌后,焊缝熔合区和焊缝中心区的平均晶粒尺寸分别减小了57.9%和55%;不含铌以及铌质量分数分别为0.74%和1.36%的焊接接头的平均抗拉强度分别为325,334.5,328 MPa;铌质量分数为0.74%的焊接接头的断后延伸率为6%,与未加铌的相比,提高了约71%;三种试样的拉伸断口均以韧窝为为主,并伴随有明显的撕裂棱,表现出微孔聚集型断裂特征。

Abstract

The butt joint of A7204P-T4 aluminum alloy sheets with a thickness of 6 mm was welded via fiber laser-cold metal transition (CMT) arc hybrid welding, with various sizes of niobium foil attached to the butt interface before welding (niobium mass fractions were 0.74% and 1.36% in the weld). Well-formed joints were obtained by optimizing the process parameters. The effects of niobium contents on microstructure and mechanical properties of hybrid welded joints were studied, and the tensile fracture mechanism and fracture morphology of welded joints were also analyzed. Experimental results show that the microstructure of niobium-free welds mainly comprises fine crystal regions, columnar crystalline regions, and equiaxed dendrite regions. After adding niobium foil, grain refinement was observed in the weld metal due to the segregation of niobium solute and heterogeneous nucleation of niobium precipitates, and the apparent disappearance of columnar and dendritic structures were also obserbed. After mass fraction of 0.74% niobium was added, the average grain sizes of fusion zone and weld center decreased by 57.9% and 55%, respectively. The average tensile strength of the joints without niobium, 0.74% and 1.36% mass fraction of niobium were 325 MPa, 334.5 MPa and 328 MPa. The post-break elongation of the welded joint with a mass fraction of 0.74% niobium was 6%, increasing by 71% compared to joint without niobium addition. The fracture surfaces of the three tensile test samples were mainly dimples accompanied by obvious tearing edges, showing microporous aggregate fracture characteristics.

栗忠秀, 温鹏, 张松, 吴世凯. 铌微合金化对光纤激光-CMT复合焊接A7204P-T4 铝合金接头组织和力学性能的影响[J]. 中国激光, 2020, 47(9): 0902001. Li Zhongxiu, Wen Peng, Zhang Song, Wu Shikai. Effects of Nb Micro-Alloying on Microstructure and Mechanical Properties of A7204P-T4 Aluminum Alloy Joint by Fiber Laser-CMT Hybrid Welding[J]. Chinese Journal of Lasers, 2020, 47(9): 0902001.