中国激光, 2020, 47 (1): 0102001, 网络出版: 2020-01-09

δ时效处理对激光增材修复Inconel 718合金组织与性能的影响  下载: 1309次

下载: 1309次

Effect of δ Aging Treatment on Microstructure and Tensile Properties of Repaired Inconel 718 Alloy Using Laser Additive Manufacturing

激光技术 激光增材修复 Inconel 718 δ相析出机制; 拉伸性能 laser technique laser additive repair Inconel 718 δ phase precipitation mechanism; tensile properties

摘要

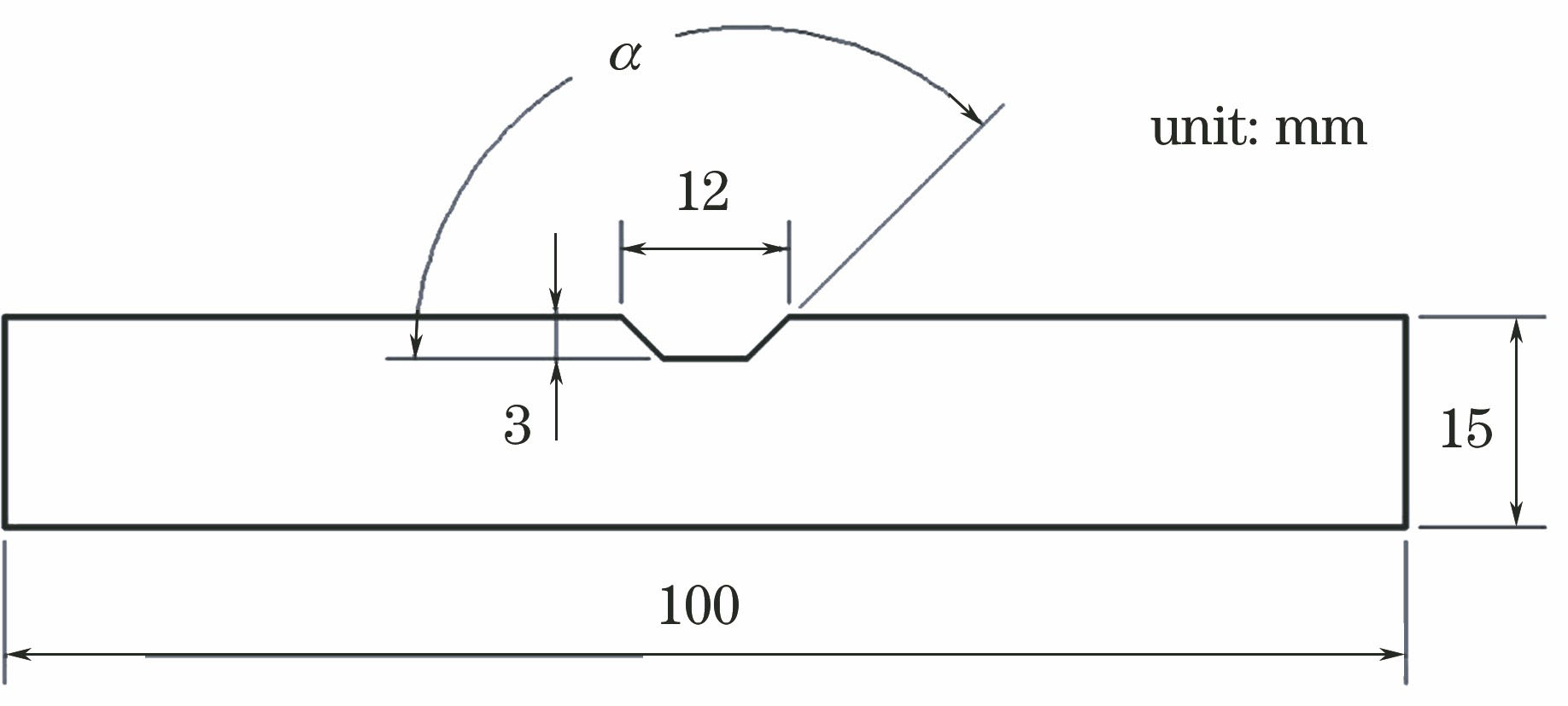

采用激光增材修复技术和Inconel 718 球形粉末对预制凹槽的Inconel 718合金进行逐层修复,然后在800 ℃下进行不同时间(4,8,16,32 h)的δ时效处理,研究了时效时间对修复层组织和性能的影响。结果表明:随着时效时间延长,修复层中的Laves相和强化相γ″相逐渐消失,而δ相通过切变的方式在γ″相密排面层错的基础上形核并长大。修复区中的δ相在残余Laves相周围呈细针状析出,并随着时效时间的延长而变大;而母材中的δ相优先在晶界处形核长大,最终在晶粒内以平行式生长。虽然时效处理能够有效提高修复区及母材的显微硬度及抗拉强度,但随着时效时间的持续增加,硬度及力学性能均呈现下降的趋势;修复区及母材的显微硬度在时效4 h时分别达到最高值361 HV和465 HV,之后随着时效时间的延长而逐渐下降;不同时效处理后的修复件的拉伸断裂部位均位于修复区,断口整齐,呈典型的脆性断裂。

Abstract

Inconel 718 alloys with premade grooves are repaired layer by layer with Inconel 718 spherical powder via the laser additive manufacturing process. The repaired Inconel 718 alloys are then subjected to δ aging treatment at 800 ℃ for different time (4, 8, 16, and 32 h) to study the effect of the aging time on the microstructure and tensile properties of the repaired layer. The results show that the Laves and strengthened γ″ phases in the repaired layer gradually disappear with the increase of the aging time, whereas the δ phase nucleates and grows on the basis of the stacking faults of the γ″ phase on the close-packed plane through the shearing mechanism. In addition, needle-like precipitates appear in the δ phase of the repaired zone around the residual Laves phase and become larger with aging time. However, precipitates in the substrate metal preferentially nucleate and grow at the grain boundaries and eventually grow in parallel within the grains. Although the aging treatment can effectively improve the microhardness and tensile strength of the repaired zone and the substrate metal of Inconel 718 alloys, the hardness and mechanical properties decrease as the aging time continues to increase. After aging treatment for 4 h, the microhardnesses of the repaired zone and the substrate metal reach the highest values of 361 HV and 465 HV, respectively, and then gradually decrease with the aging time. Furthermore, with different aging treatments, all the tensile fractures of the repaired parts are located in the repaired zone. The fracture surfaces are flat, showing typical brittle fracture characteristics.

张杰, 张群莉, 李栋, 童文华, 姚建华, 冷志斌. δ时效处理对激光增材修复Inconel 718合金组织与性能的影响[J]. 中国激光, 2020, 47(1): 0102001. Jie Zhang, Qunli Zhang, Dong Li, Wenhua Tong, Jianhua Yao, Zhibin Leng. Effect of δ Aging Treatment on Microstructure and Tensile Properties of Repaired Inconel 718 Alloy Using Laser Additive Manufacturing[J]. Chinese Journal of Lasers, 2020, 47(1): 0102001.