Two-step solvent post-treatment on PTAA for highly efficient and stable inverted perovskite solar cells  Download: 861次

Download: 861次

1 Joint Key Laboratory of the Ministry of Education, Institute of Applied Physics and Materials Engineering, University of Macau, Macao SAR, 999078, China

2 Guangdong Key Laboratory of Nano-Micro Material Research, School of Chemical Biology and Biotechnology, Shenzhen Graduate School, Peking University, Shenzhen 518055, China

3 Department of Physics and Chemistry, Faculty of Science and Technology, University of Macau, Macao SAR, 999078, China

4 e-mail: gcxing@um.edu.mo

5 e-mail: huipan@um.edu.mo

Figures & Tables

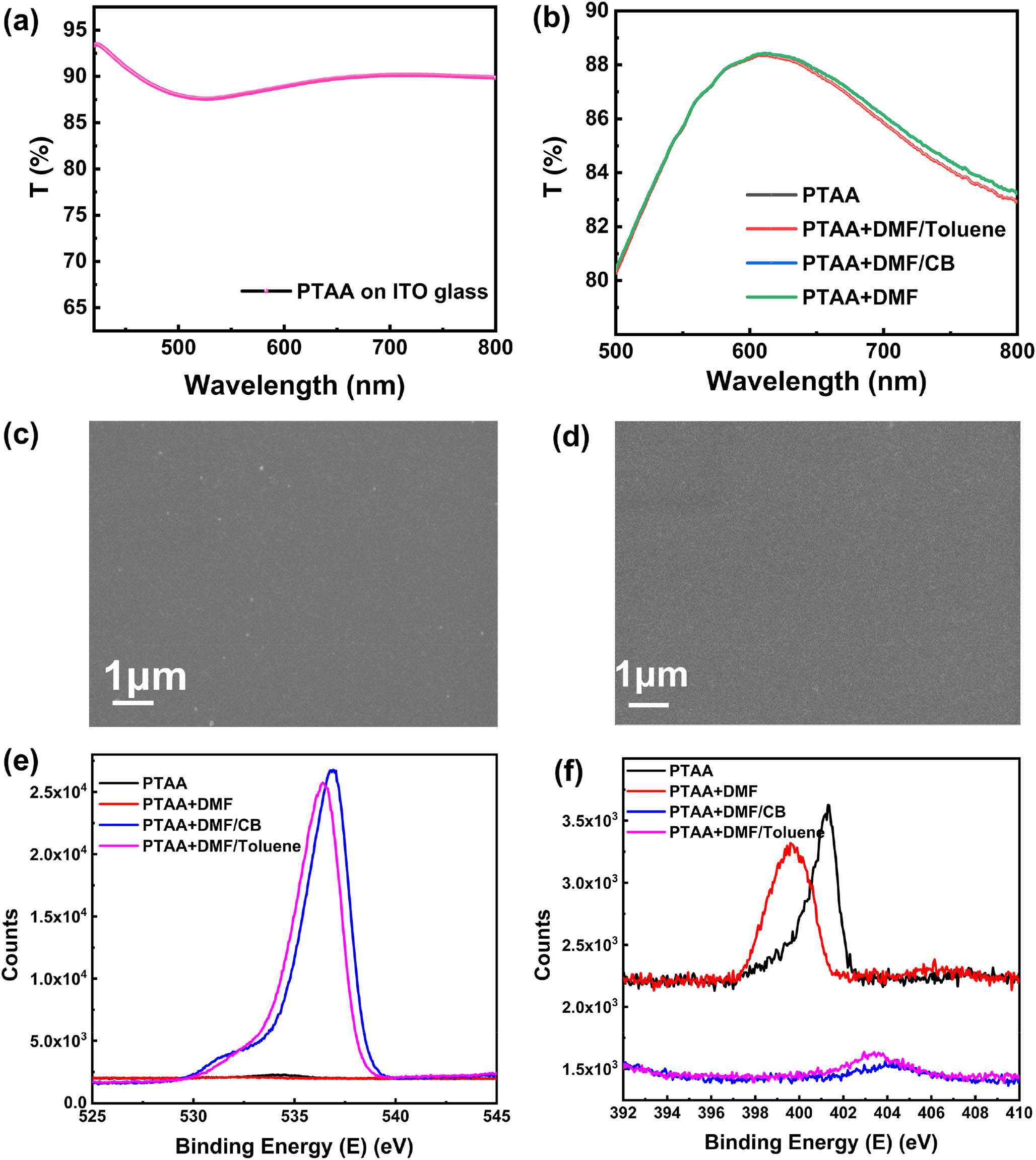

Fig. 1. Transmittance of PTAA on (a) ITO glass and on (b) electronic grade pure glass; SEM (scale bar=1 μm) images of (c) ITO glass and (d) PTAA precursor covered ITO glass. XPS profiles for PTAA, PTAA+DMF, PTAA+DMF/CB, and PTAA+DMF/toluene on ITO substrate: (e) scan for O 1s; (f) scan for N 1s.

下载图片 查看原文

Fig. 2. AFM phase images (500 nm×500 nm) of (a) ITO/PTAA, (b) ITO/PTAA/DMF, (c) ITO/PTAA/DMF/toluene, and (d) ITO+PTAA/DMF/CB. (Insets show the 3D morphology for each film and RMS reflects the film roughness.)

下载图片 查看原文

Fig. 3. (a)–(c) Cross-sectional SEM images for devices with PTAA, PTAA/DMF/CB, and PTAA/DMF/toluene as HTLs, respectively. (d)–(h) Top-view SEM images of perovskite film on glass/PTAA, glass, glass/PTAA/DMF/toluene, glass/PTAA/DMF, and glass/PTAA/DMF/CB. (Red circles show pin holes.) (i)–(l) Contact angles for (i) PTAA; (j) PTAA/DMF; (k) PTAA/DMF/CB, and (l) PTAA+DMF/toluene on glass.

下载图片 查看原文

Fig. 4. Top-view AFM images (1 μm×1 μm) of perovskites on PTAA with different solvent modification during (rotating state) or after spin coating of DMF (stable state): (a) glass/PTAA/DMF/toluene (drop under stable state)+PSK; (b) glass/PTAA/PSK; (c) glass/PTAA/DMF/toluene (drop while rotating)/PSK; (d) glass/PTAA/DMF/PSK; (e) glass+PTAA/DMF/CB (drop while rotating)/PSK; (f) glass+PTAA/DMF/CB (drop under stable state)/PSK.

下载图片 查看原文

Fig. 5. (a) XRD patterns and (b) UV-vis absorption spectra for PTAA/PSK, PTAA/DMF/PSK, PTAA/DMF/CB/PSK, and PTAA/DMF/toluene/PSK on ITO substrates. (c) Steady-state PL and (d) TRPL spectra for PSCs corresponding to the films in (a) and (b).

下载图片 查看原文

Fig. 6. (a) J-V curve under 1.5G sunlight through a solar simulator by reverse scan for PSCs using PTAA with different concentrations (device structure: ITO/PTAA/PSK/PCBM/BCP/Ag). (b) Best device based on toluene-treated PTAA. (c) to (g) J-V curves for devices based on different PTAA substrates by reverse and forward scans: (d) PTAA without any treatment; (e) PTAA treated with DMF; (f) PTAA treated with DMF/CB. The active area for the above cells is 0.05 cm2.

下载图片 查看原文

Fig. 7. (a) Device structure. (b) Enlarged drawing of toluene between PTAA and perovskite. (c) Energy-level diagram of each layer in the device. (d) Fabrication process of PSCs based on DMF/toluene-treated PTAA. (e) J-V curves (by reverse scan) for the devices in this research. (f) Nyquist plot for PSCs with pristine PTAA and PTAA treated by DMF, DMF/CB, and DMF/toluene, respectively (bias voltage=0.6 V, frequency in range of 0.1–100 Hz). (g) IPCE curves of PSCs by using PTAA, PTAA/DMF, PTAA/DMF/CB, and PTAA/DMF/toluene as HTLs. (h) Long-term stability test for PSCs fabricated based on PTAA treated by different solvents in ambient with humidity above 35% and temperature around RT.

下载图片 查看原文

Fig. 8. Data difference analysis for 36 PSCs by using toluene-treated PTAA as hole transport material in inverted structure.

下载图片 查看原文

Fig. 9. Photovoltaic parameters of the best device (with DMF/toluene modified PTAA as HTL) newly prepared as well as after storage in N2-filled glove box for 10 and 20 days (measured under continuous 1.5G light illumination, 30 s once, in ambient). Relationships between exposure time and exposure time and (a) efficiency, (b) Jsc, (c) Voc, and (d) FF, respectively.

下载图片 查看原文

Table1. Film Thickness Measurement Result by a Step Profiler

| Group | PTAA+DMF+CB+PSK | PTAA+DMF+toluene+PSK | PTAA+DMF+PSK | PTAA | | Thickness | 450 nm | 456 nm | 459 nm | 15 nm |

|

查看原文

Table2. Contact Angle Measurement Results Corresponding to PTAA with Different Solvent Treatmenta

| Group | | | | | PTAA | 107.30 | 106.49 | 108.10 | | PTAA/DMF | 106.80 | 106.68 | 106.92 | | PTAA/CB | 60.48 | 60.91 | 60.04 | | PTAA/toluene | 81.94 | 84.06 | 79.80 |

|

查看原文

Table3. TRPL Time Decay Analysis Through Double Exponential Fitting Method

| Group | A1 | A2 | (ns) | (ns) | (ns) | | PTAA/DMF/CB/PSKa | 126.65 | 1.96 | 1.82 | 7.41 | 2.15 | | PTAA/DMF/toluene/PSKa | 211.51 | 2.66 | 1.72 | 5.66 | 1.88 | | PTAA/DMF/PSK | 10.03 | 0.94 | 3.48 | 11.40 | 5.35 | | PTAA/DMF/toluene/PSKb | 236.25 | 1.99 | 1.56 | 8.69 | 1.88 | | PTAA/DMF/CB/PSKb | 26.54 | 1.56 | 2.61 | 7.72 | 3.37 | | PTAA/PSK | 16.95 | 0.86 | 2.72 | 17.86 | 6.50 |

|

查看原文

Table4. Long-Term Stability for Devices with Pristine PTAA Compared with PTAA Treated by DMF, DMF/Toluene, and DMF/CB, with Different Storage Times

| Storage Time | | | Efficiency (%) | | | PTAA | PTAA/DMF | PTAA/DMF/toluene | PTAA/DMF/CB | | 24 h | 17.20 | 16.86 | 19.31 | 18.78 | | 240 h | 16.84 | 15.95 | 18.78 | 17.88 | | 480 h | 13.29 | 15.65 | 18.24 | 16.37 | | 720 h | 4.79 | 7.05 | 17.07 | 15.00 |

|

查看原文

Table5. Photovoltaic Parameters of the Best Solar Cell with Toluene-Treated PTAA as HTL at Different Storage Times (Measured 21 Times, 30 s Once Under Continuous 1.5G Sunlight Without Encapsulation)

| Parameters | Fresh Cells | 10 Days Later | 20 Days Later | | FF | Average | 78.00 | 78.60 | 78.94 | | Maximum | 80.11 | 81.64 | 80.65 | | () | Average | 23.44 | 21.95 | 20.87 | | Maximum | 23.87 | 23.63 | 22.72 | | Efficiency (%) | Average | 18.95 | 17.00 | 15.75 | | Maximum | 19.51 | 17.68 | 16.17 | | (V) | Average | 1.02 | 1.00 | 0.96 | | Maximum | 1.09 | 1.10 | 0.98 |

|

查看原文

Yang Li, Chao Liang, Gaopeng Wang, Jielei Li, Shi Chen, Shihe Yang, Guichuan Xing, Hui Pan. Two-step solvent post-treatment on PTAA for highly efficient and stable inverted perovskite solar cells[J]. Photonics Research, 2020, 8(10): 10000A39.

Download: 861次

Download: 861次