纳秒脉冲激光铣削Al2O3陶瓷工艺参数的优化  下载: 875次

下载: 875次

Process Parameter Optimization of Al2O3 Ceramics Milled with Nanosecond Pulsed Laser

1 淮阴工学院江苏省先进制造技术重点实验室, 江苏 淮安 223003

2 江苏大学先进制造与现代装备技术工程研究院, 江苏 镇江 212013

3 江苏大学机械工程学院, 江苏 镇江 212013

图 & 表

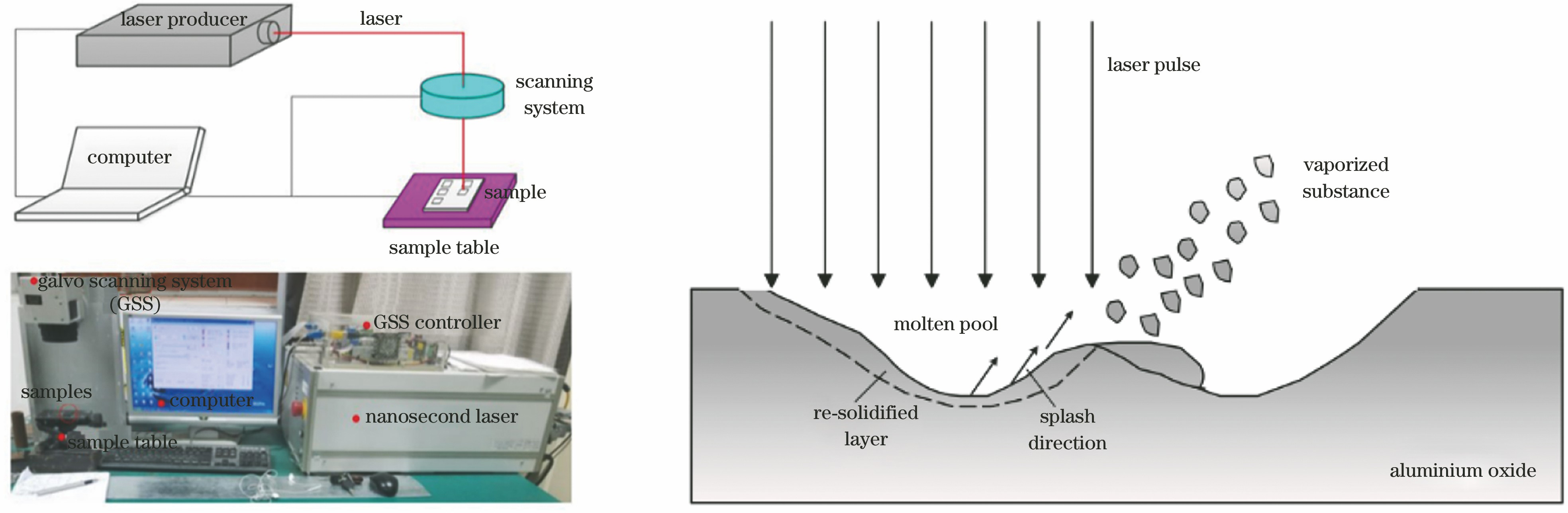

图 1. 激光铣削实验系统及激光铣削原理示意图。(a)实验系统;(b)铣削原理示意图

Fig. 1. Experimental system of laser milling and principle of laser milling. (a) Experimental system; (b) milling schematic

下载图片 查看原文

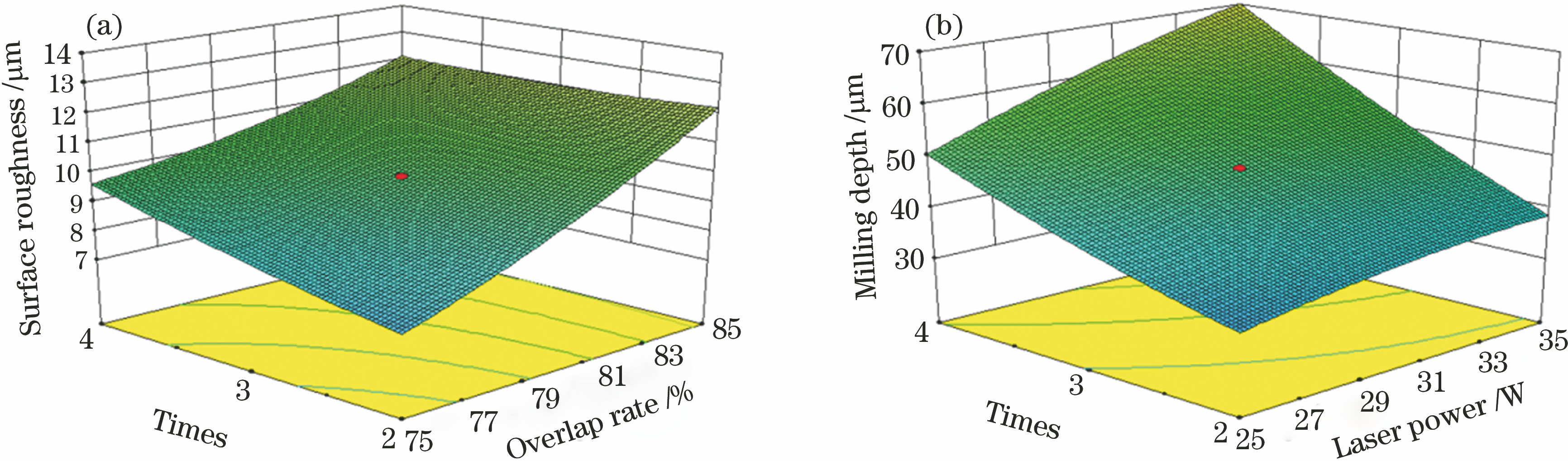

图 2. 工艺参数对铣削质量的交互式影响。(a)对表面粗糙度的影响;(b)对铣削深度的影响

Fig. 2. Interactive effects of process parameters on milling quality. (a) Effect on surface roughness; (b) effect on milling depth

下载图片 查看原文

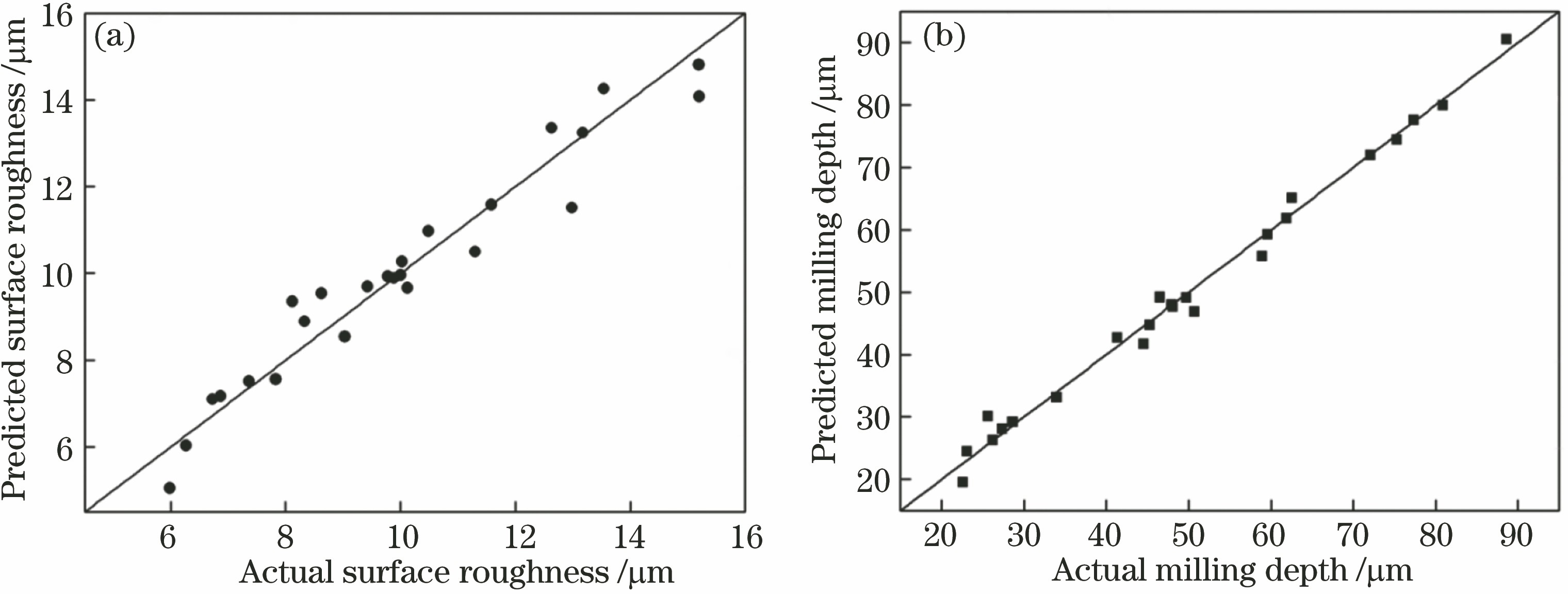

图 3. 预测值与实际值的对比。(a)表面粗糙度;(b)铣削深度

Fig. 3. Comparison of predicted and actual values. (a) Surface roughness; (b) milling depth

下载图片 查看原文

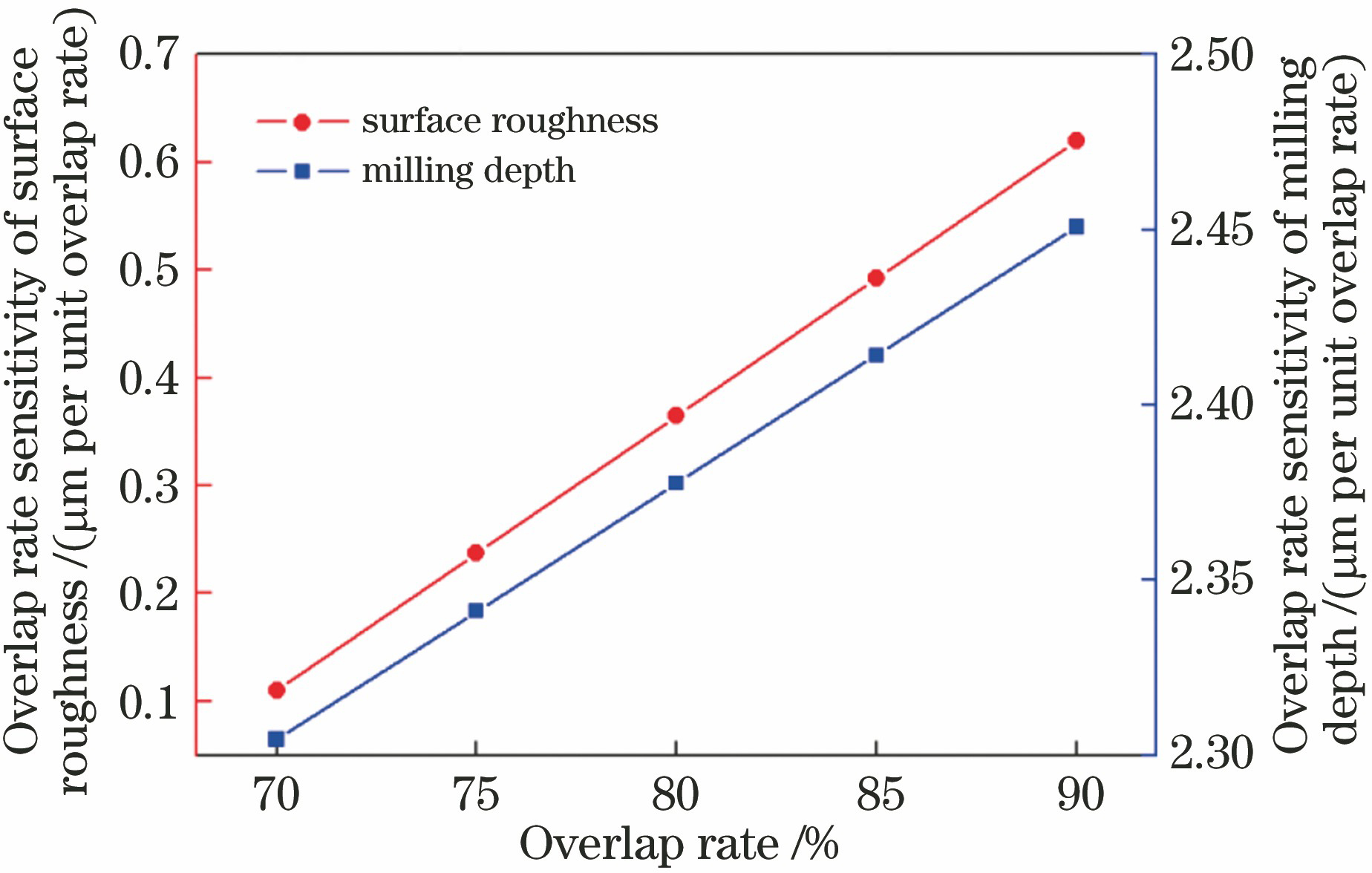

图 4. 搭接率对铣削质量的灵敏度分析结果(激光功率为30 W,铣削次数为3,重复频率为40 kHz)

Fig. 4. Analysis results of sensitivity of overlap rate to milling quality (laser power is 30 W, milling times is 3, and laser repetition rate is 40 kHz)

下载图片 查看原文

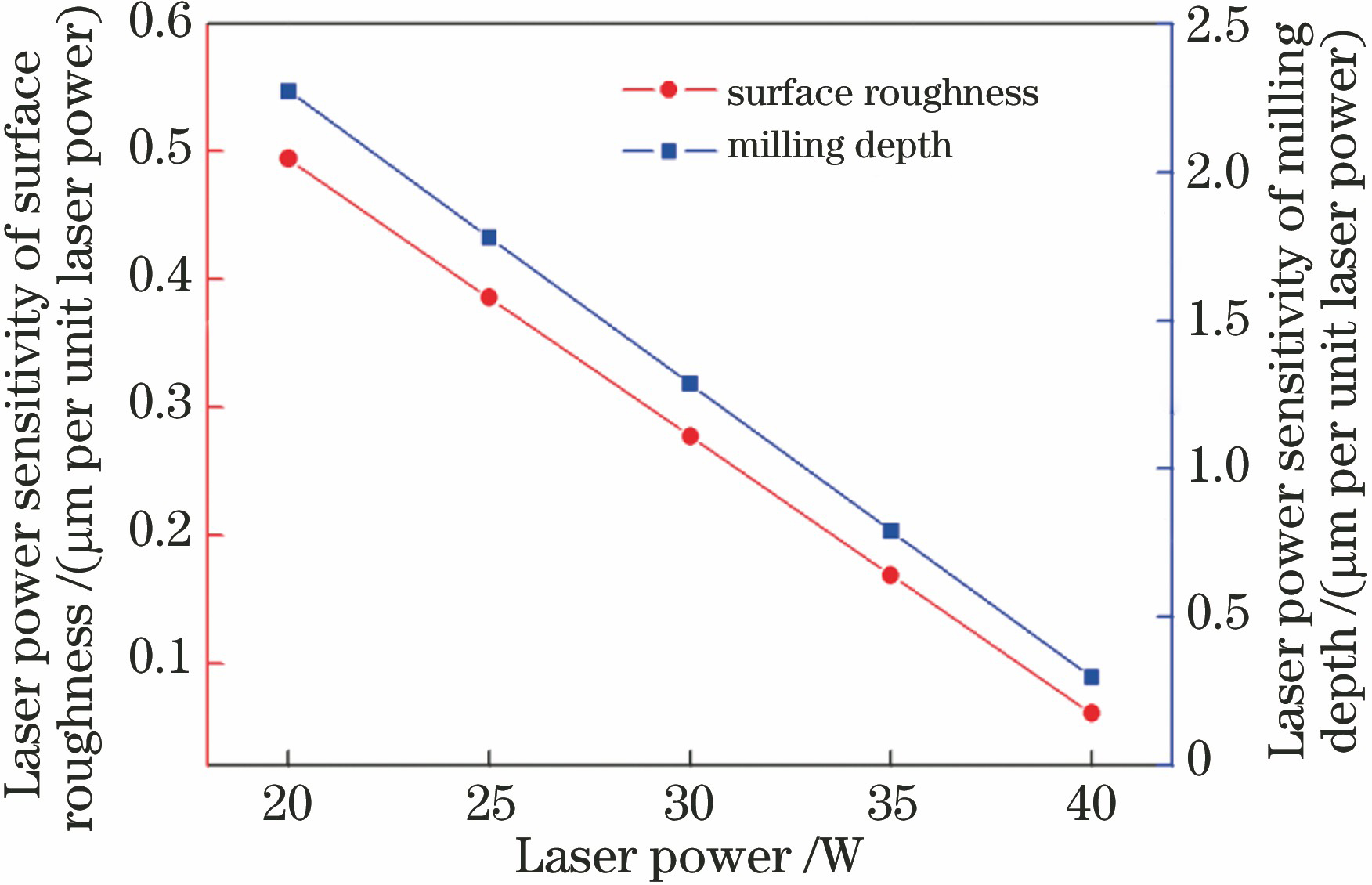

图 5. 激光功率对铣削质量的灵敏度分析结果(搭接率为80%,铣削次数为3,重复频率为40 kHz)

Fig. 5. Analysis results of sensitivity of laser power to milling quality (overlap rate is 80%, milling times is 3, and laser frequency is 40 kHz)

下载图片 查看原文

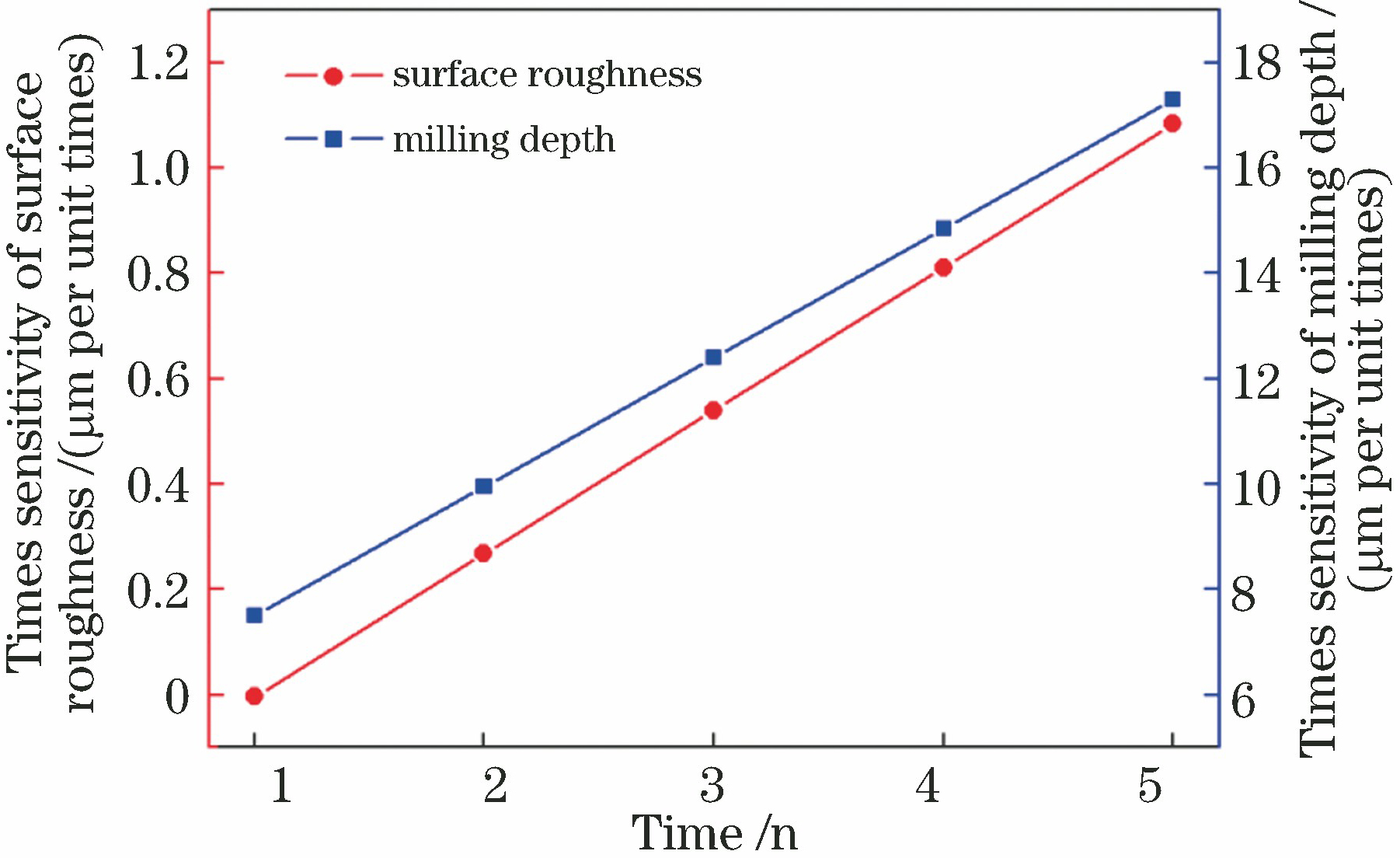

图 6. 铣削次数对铣削质量的灵敏度分析结果(搭接率为80%,激光功率为30 W,重复频率为40 kHz)

Fig. 6. Analysis results of sensitivity of laser milling times to milling quality (overlap rate is 80%, laser power is 30 W, and laser repetition rate is 40 kHz)

下载图片 查看原文

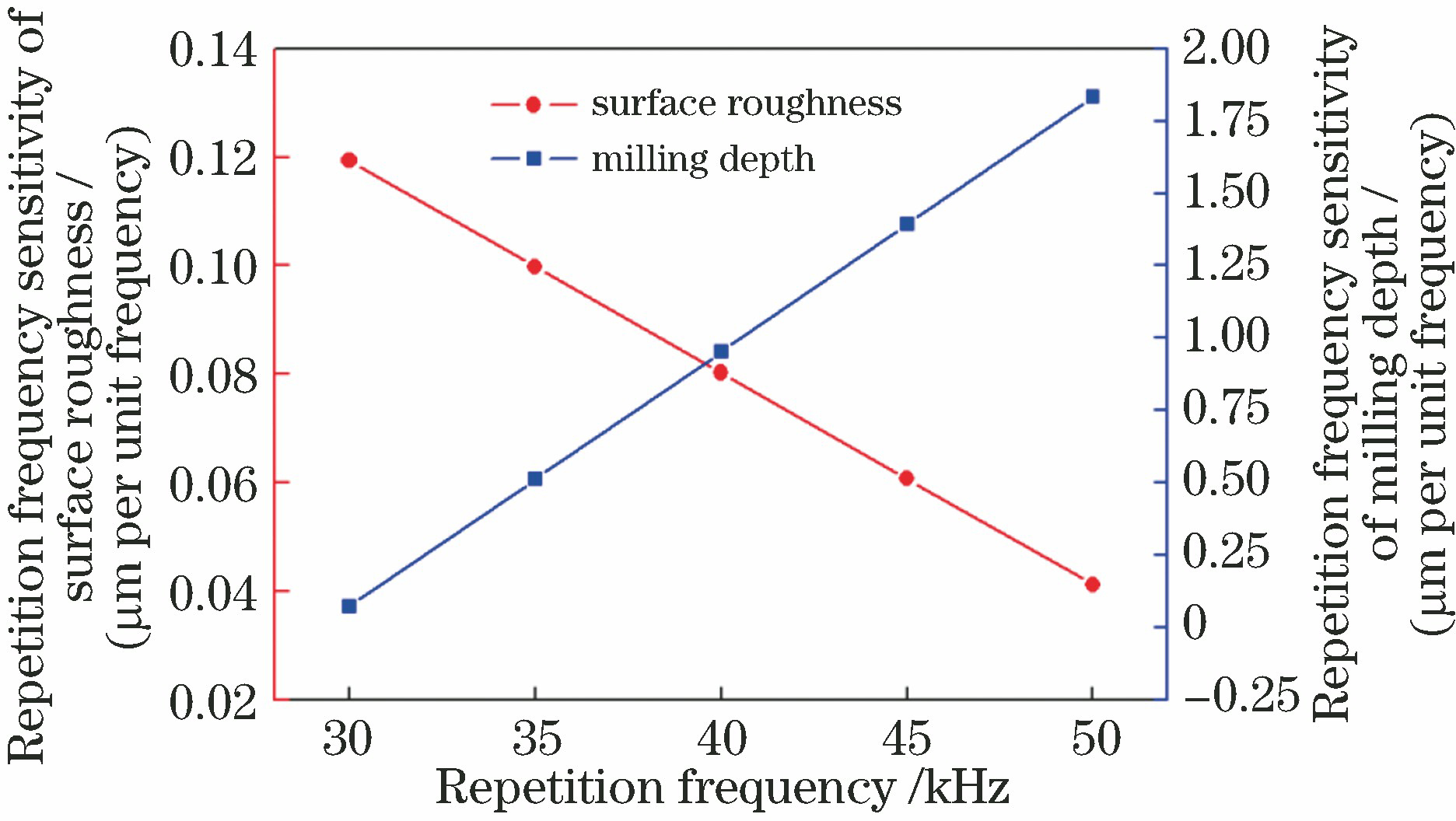

图 7. 重复频率对铣削质量的灵敏度分析结果(搭接率为80%,激光功率为30 W,铣削次数为3)

Fig. 7. Analysis results of sensitivity of laser frequency to milling quality (overlap rate is 80%, laser power is 30 W, and milling times is 3)

下载图片 查看原文

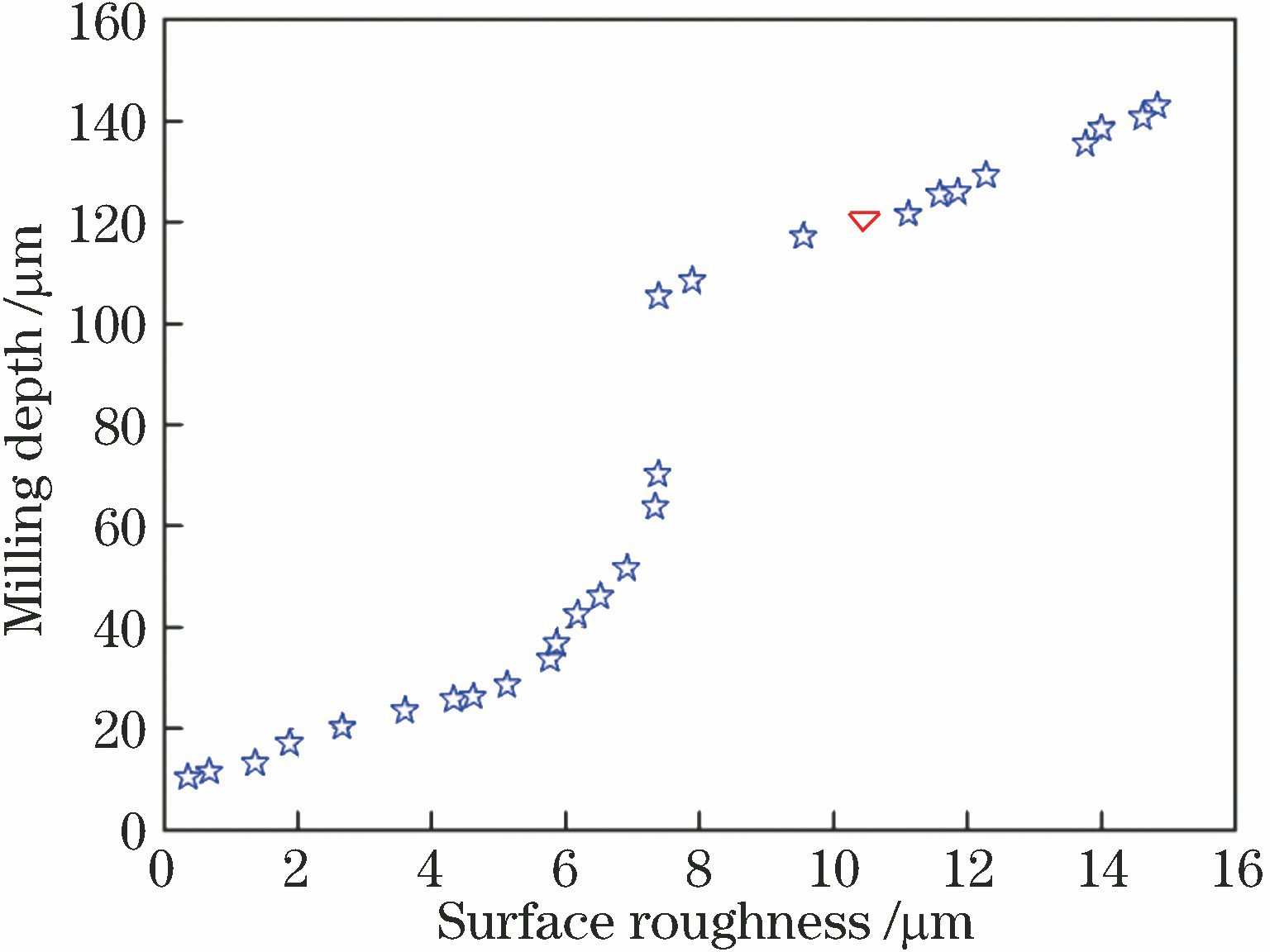

图 8. 多目标优化结果

Fig. 8. Results of multi-objective optimization

下载图片 查看原文

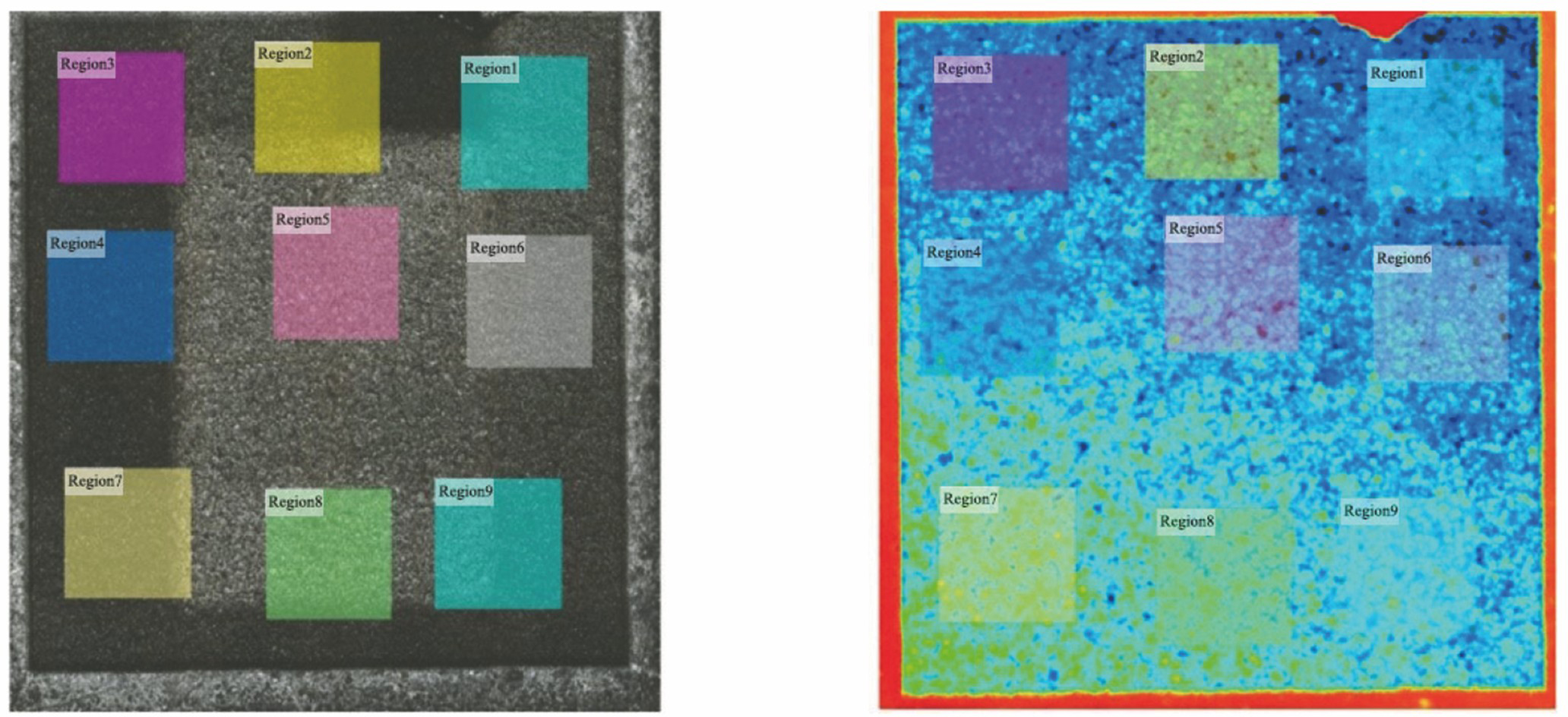

图 9. 表面粗糙度的测量区域

Fig. 9. Measurement area of surface roughness

下载图片 查看原文

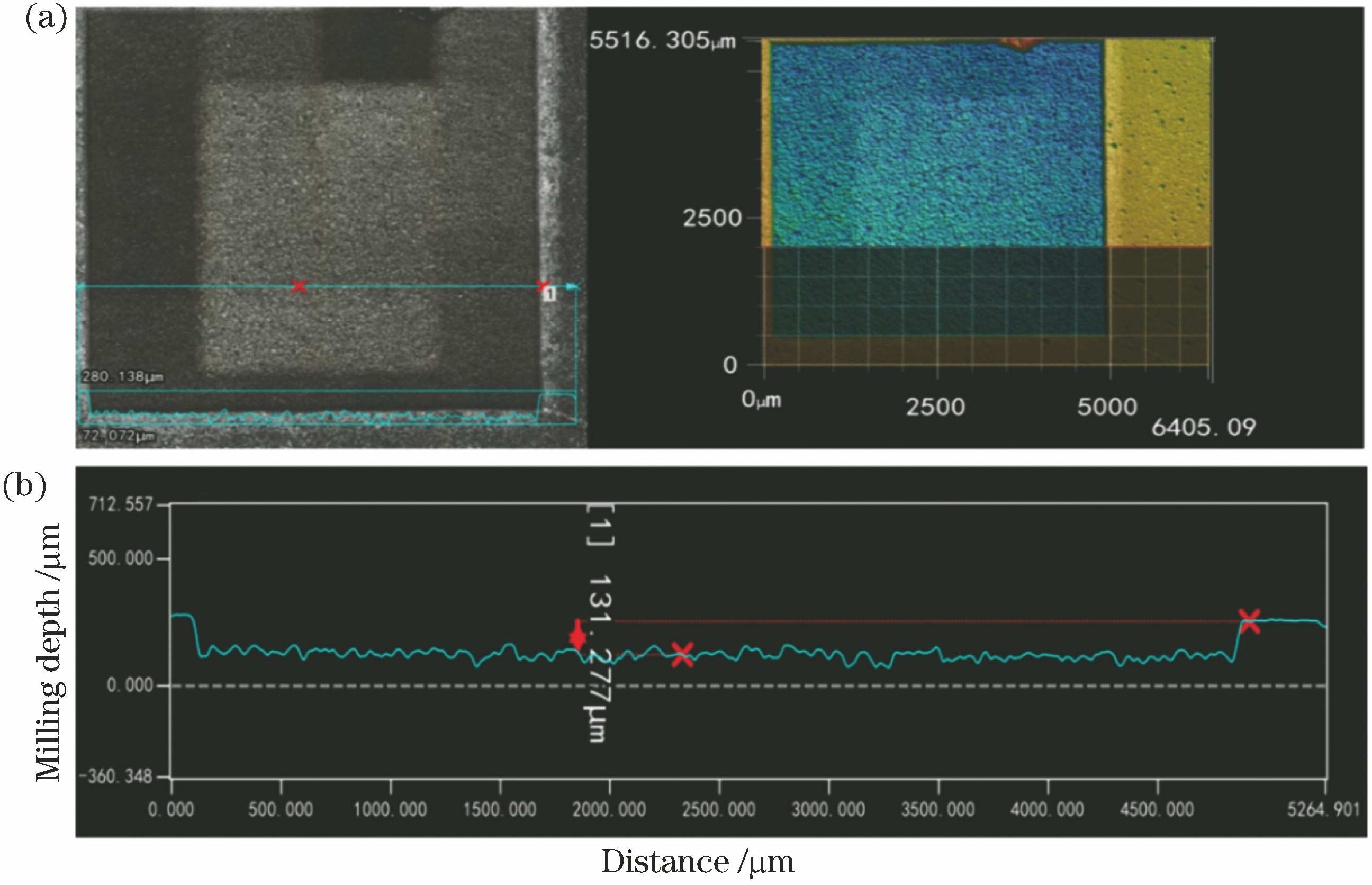

图 10. 激光铣削的三维形貌和截面轮廓。(a)三维形貌;(b)截面轮廓(搭接率为90%,激光功率为25.6 W,铣削次数为5,重复频率为50 kHz)

Fig. 10. Three-dimensional topography and sectional profile after laser milling. (a) Three-dimensional topography; (b) sectional profile (overlap rate is 90%, laser power is 25.6 W, milling times is 5, and laser repetition rate is 50 kHz)

下载图片 查看原文

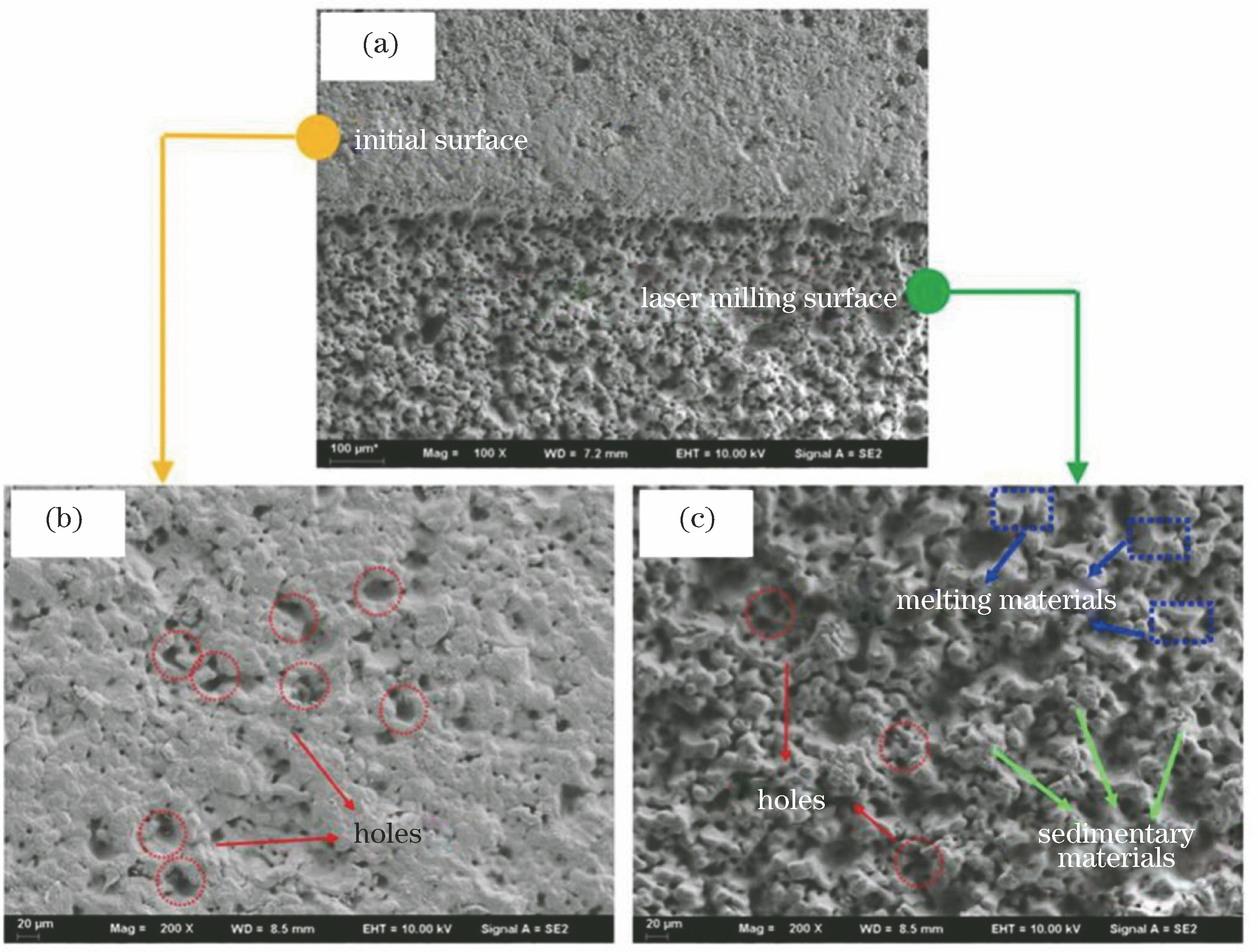

图 11. 激光铣削前后陶瓷表面的微观组织。(a)初始表面与铣削表面;(b)初始表面放大图;(c)铣削表面放大图(搭接率为90%,激光功率为25.6 W,铣削次数为5,重复频率为50 kHz)

Fig. 11. Microstructures of ceramic surface before and after laser milling. (a) Initial surface and milled surface; (b) partial enlargement of initial surface; (c) partial enlargement of milled surface (overlap rate is 90%, laser power is 25.6 W, milling times is 5, and laser repetition rate is 50 kHz).

下载图片 查看原文

表 1工艺参数及其取值范围

Table1. Process parameters and their value ranges

| Parameter | Notation | Unit | Level |

|---|

| -2 | -1 | 0 | 1 | 2 |

|---|

| Overlap rate | O | % | 70 | 75 | 80 | 85 | 90 | | Laser power | P | W | 20 | 25 | 30 | 35 | 40 | | Times | N | - | 1 | 2 | 3 | 4 | 5 | | Repetition frequency | F | kHz | 30 | 35 | 40 | 45 | 50 |

|

查看原文

表 2实验设计矩阵及结果

Table2. Experimental design matrix and results

| No. | O /% | P /W | N | F /kHz | Ra /μm | M /μm |

|---|

| 1 | 85 | 35 | 2 | 35 | 15.208 | 46.515 | | 2 | 80 | 30 | 3 | 40 | 9.890 | 47.879 | | 3 | 80 | 30 | 3 | 30 | 8.325 | 41.299 | | 4 | 80 | 30 | 3 | 40 | 9.890 | 47.879 | | 5 | 85 | 35 | 4 | 35 | 13.537 | 80.920 | | 6 | 80 | 30 | 1 | 40 | 8.115 | 26.826 | | 7 | 80 | 20 | 3 | 40 | 6.265 | 25.588 | | 8 | 80 | 30 | 3 | 40 | 9.890 | 47.879 | | 9 | 85 | 25 | 2 | 45 | 10.025 | 45.272 | | 10 | 80 | 30 | 3 | 50 | 10.297 | 61.911 | | 11 | 80 | 30 | 5 | 40 | 12.984 | 77.373 | | 12 | 85 | 25 | 4 | 45 | 9.782 | 75.285 | | 13 | 75 | 25 | 4 | 35 | 6.726 | 26.160 | | 14 | 85 | 25 | 2 | 35 | 10.006 | 44.521 | | 15 | 80 | 30 | 3 | 40 | 9.890 | 47.879 | | 16 | 75 | 25 | 2 | 45 | 7.828 | 27.382 | | 17 | 90 | 30 | 3 | 40 | 15.198 | 72.113 | | 18 | 75 | 25 | 4 | 45 | 8.625 | 50.697 | | 19 | 80 | 30 | 3 | 40 | 9.890 | 47.879 | | 20 | 85 | 35 | 2 | 45 | 13.171 | 48.069 | | 21 | 80 | 40 | 3 | 40 | 11.582 | 58.944 | | 22 | 85 | 35 | 4 | 45 | 12.632 | 88.637 | | 23 | 85 | 25 | 4 | 35 | 9.425 | 59.550 | | 24 | 75 | 35 | 2 | 45 | 9.032 | 33.958 | | 25 | 70 | 30 | 3 | 40 | 7.361 | 23.022 | | 26 | 75 | 35 | 4 | 45 | 10.482 | 62.510 | | 27 | 75 | 35 | 4 | 35 | 10.125 | 49.719 | | 28 | 75 | 35 | 2 | 35 | 6.871 | 28.622 | | 29 | 75 | 25 | 2 | 35 | 5.987 | 22.584 | | 30 | 80 | 30 | 3 | 40 | 9.890 | 47.879 |

|

查看原文

表 3响应面模型的统计学评价

Table3. Statistical evaluation of response surface model

| Parameter | Number of data points | Fitting degree | Adequate precision | p-value |

|---|

| Model of surface roughness | 30 | 0.9404 | 16.855 | <0.0001 | | Model of milling depth | 30 | 0.9905 | 41.265 | <0.0001 |

|

查看原文

许兆美, 孟宪凯, 屈彦荣, 朱为国, 郭召恒. 纳秒脉冲激光铣削Al2O3陶瓷工艺参数的优化[J]. 激光与光电子学进展, 2019, 56(23): 231404. Zhaomei Xu, Xiankai Meng, Yanrong Qu, Weiguo Zhu, Zhaoheng Guo. Process Parameter Optimization of Al2O3 Ceramics Milled with Nanosecond Pulsed Laser[J]. Laser & Optoelectronics Progress, 2019, 56(23): 231404.

下载: 875次

下载: 875次