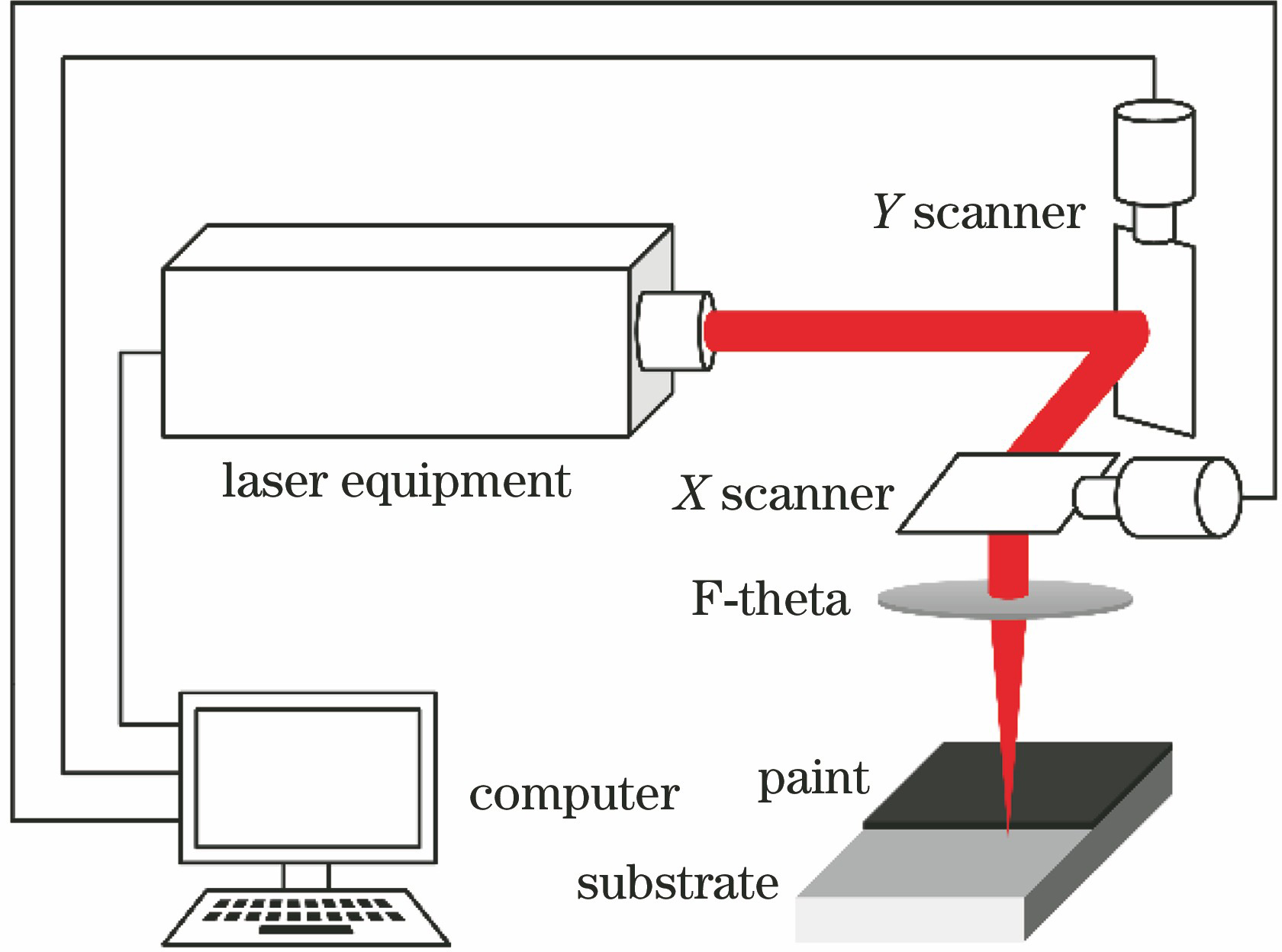

基于响应面分析的激光除漆工艺参数优化  下载: 1035次

下载: 1035次

杨嘉年, 周建忠, 孙奇, 孟宪凯, 朱明, 郭召恒, 付强. 基于响应面分析的激光除漆工艺参数优化[J]. 激光与光电子学进展, 2019, 56(23): 231402.

Jianian Yang, Jianzhong Zhou, Qi Sun, Xiankai Meng, Ming Zhu, Zhaoheng Guo, Qiang Fu. Laser Paint Removal Process Parameter Optimization via Response Surface Methodology[J]. Laser & Optoelectronics Progress, 2019, 56(23): 231402.

[1] Chillman A, Ramulu M, Hashish M. Waterjet and water-air jet surface processing of a titanium alloy: a parametric evaluation[J]. Journal of Manufacturing Science and Engineering, 2010, 132(1): 011012.

[2] 任工昌, 于峰海, 陈红柳. 绿色再制造清洗技术的现状及发展趋势研究[J]. 机床与液压, 2014, 42(3): 158-161.

Ren G C, Yu F H, Chen H L. Present situation and development trend of green remanufacturing cleaning technology[J]. Machine Tool & Hydraulics, 2014, 42(3): 158-161.

[3] 陈一鸣, 周龙早, 闫飞, 等. 铝合金激光清洗机理与质量评估[J]. 中国激光, 2017, 44(12): 1202005.

[4] Shamsujjoha M, Agnew S R, Melia M A, et al. Effects of laser ablation coating removal (LACR) on a steel substrate: surface profile, microstructure, hardness, and adhesion[J]. Surface and Coatings Technology, 2015, 281: 193-205.

[5] 王泽敏, 曾晓雁, 黄维玲. 激光清洗轮胎模具表面橡胶层的机理与工艺研究[J]. 中国激光, 2000, 27(11): 1050-1054.

[6] 施曙东, 杜鹏, 李伟, 等. 1064 nm准连续激光除漆研究[J]. 中国激光, 2012, 39(9): 0903001.

[7] 章恒, 刘伟嵬, 董亚洲, 等. 低频YAG脉冲激光除漆机理和实验研究[J]. 激光与光电子学进展, 2013, 50(12): 121401.

[8] 王德良, 冯国英, 邓国亮, 等. 基于颗粒形貌及成分分析的激光除漆去除机理研究[J]. 中国激光, 2015, 42(10): 1003007.

[9] Li F, Chen X G, Lin W H, et al. Nanosecond laser ablation of Al-Si coating on boron steel[J]. Surface and Coatings Technology, 2017, 319: 129-135.

[10] Brygo F, Dutouquet C, Le Guern F, et al. Laser fluence, repetition rate and pulse duration effects on paint ablation[J]. Applied Surface Science, 2006, 252(6): 2131-2138.

[11] D'Addona D M. Genna S, Giordano A, et al. Laser ablation of primer during the welding process of iron plate for shipbuilding industry[J]. Procedia CIRP, 2015, 33: 464-469.

[12] Jasim H A, Demir A G, Previtali B, et al. Process development and monitoring in stripping of a highly transparent polymeric paint with ns-pulsed fiber laser[J]. Optics & Laser Technology, 2017, 93: 60-66.

[13] 陈国星, 陆海峰, 赵滢, 等. 激光功率对不锈钢表面清洗效果影响的研究[J]. 光电工程, 2017, 44(12): 1217-1224, 1245.

[14] 乔玉林, 黄克宁, 梁秀兵, 等. 清洗速度对激光清洗钛合金积碳表面的形貌与组成的影响[J]. 应用激光, 2017, 37(6): 859-864.

[15] Ruggiero A, Tricarico L, Olabi A G, et al. Weld-bead profile and costs optimisation of the CO2 dissimilar laser welding process of low carbon steel and austenitic steel AISI316[J]. Optics & Laser Technology, 2011, 43(1): 82-90.

[16] Olabi A G, Alsinani F O, Alabdulkarim A A, et al. Optimizing the CO2 laser welding process for dissimilar materials[J]. Optics and Lasers in Engineering, 2013, 51(7): 832-839.

[17] 李莉, 张赛, 何强, 等. 响应面法在试验设计与优化中的应用[J]. 实验室研究与探索, 2015, 34(8): 41-45.

Li L, Zhang S, He Q, et al. Application of response surface methodology in experiment design and optimization[J]. Research and Exploration in Laboratory, 2015, 34(8): 41-45.

[18] 褚振涛, 于治水, 张培磊, 等. 基于响应面分析的T型接头激光深熔焊焊缝形貌预测及工艺参数优化[J]. 中国激光, 2015, 42(2): 0203006.

杨嘉年, 周建忠, 孙奇, 孟宪凯, 朱明, 郭召恒, 付强. 基于响应面分析的激光除漆工艺参数优化[J]. 激光与光电子学进展, 2019, 56(23): 231402. Jianian Yang, Jianzhong Zhou, Qi Sun, Xiankai Meng, Ming Zhu, Zhaoheng Guo, Qiang Fu. Laser Paint Removal Process Parameter Optimization via Response Surface Methodology[J]. Laser & Optoelectronics Progress, 2019, 56(23): 231402.