Ti3Al/GH4169异种材料激光焊接头的组织及性能  下载: 699次

下载: 699次

Microstructures and Properties of Laser Welded Dissimilar Ti3Al/GH4169 Joints

1 北京航空材料研究院3D打印研究与工程技术中心, 北京 100095

2 北京航空材料研究院航空材料检测与评价北京市重点实验室, 北京 100095

图 & 表

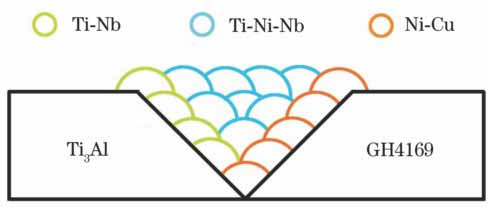

图 1. 基于Ti-Nb/Ti-Ni-Nb/Ni-Cu复合焊料的 Ti3Al/GH4169激光焊接方式示意图

Fig. 1. Schematic of laser welding of Ti3Al/GH4169 with Ti-Nb/Ti-Ni-Nb/Ni-Cu as composite filling material

下载图片 查看原文

图 2. 基于Ti-Ni-Nb焊料的Ti3Al/GH4169激光焊接头的实物照片

Fig. 2. Photograph of laser welded Ti3Al/GH4169 joints with Ti-Ni-Nb as filling material

下载图片 查看原文

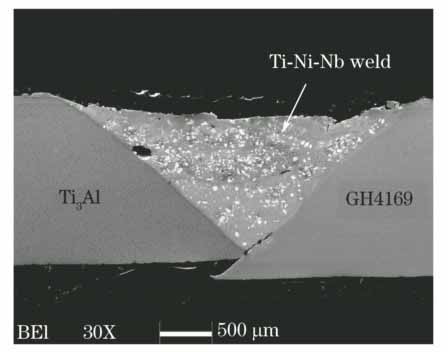

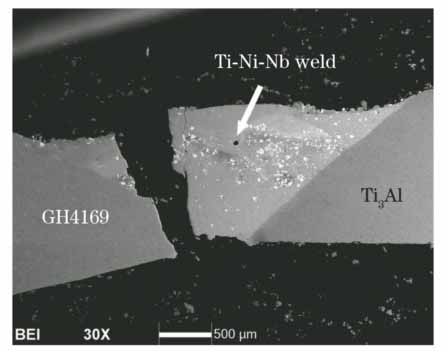

图 3. 基于Ti-Ni-Nb焊料的Ti3Al/GH4169 激光焊接头截面的BSE照片

Fig. 3. Cross sectional BSE image of laser welded Ti3Al/GH4169 joint with Ti-Ni-Nb as filling material

下载图片 查看原文

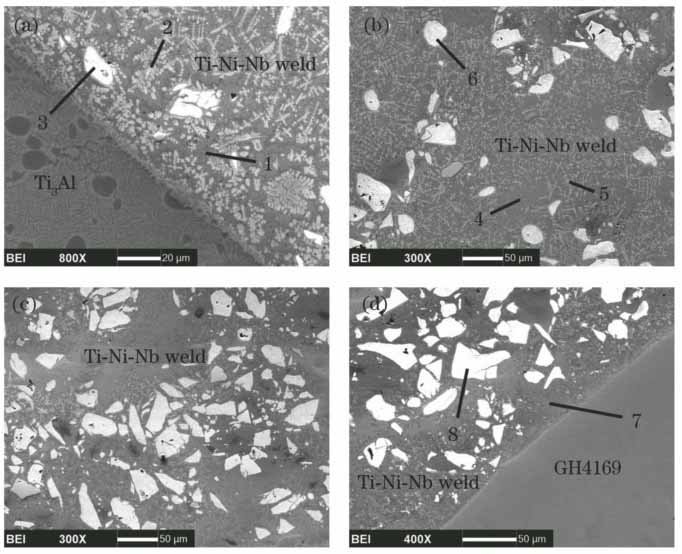

图 4. 基于Ti-Ni-Nb焊料的Ti3Al/GH4169激光焊接头截面的微观组织。(a) Ti3Al/Ti-Ni-Nb界面;(b)(c) Ti-Ni-Nb焊缝;(d) Ti-Ni-Nb/GH4169界面

Fig. 4. Cross sectional microstructure of laser welded Ti3Al/GH4169 joint with Ti-Ni-Nb as filling material. (a) Ti3Al/Ti-Ni-Nb interface; (b)(c) Ti-Ni-Nb weld; (d) Ti-Ni-Nb/GH4169 interface

下载图片 查看原文

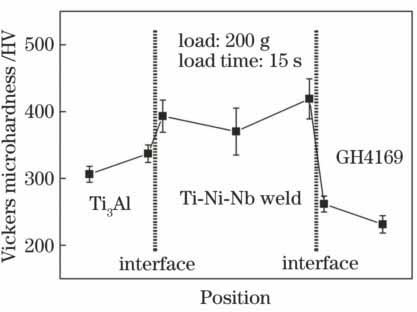

图 5. 基于Ti-Ni-Nb焊料的Ti3Al/GH4169 激光焊接头的显微硬度分布

Fig. 5. Microhardness distribution in laser welded Ti3Al/GH4169 joint with Ti-Ni-Nb as filling material

下载图片 查看原文

图 6. 基于Ti-Ni-Nb焊料的Ti3Al/GH4169 激光焊接头断裂截面的BSE照片

Fig. 6. Cross sectional BSE image of frature of laser welded Ti3Al/GH4169 joint with Ti-Ni-Nb as filling material

下载图片 查看原文

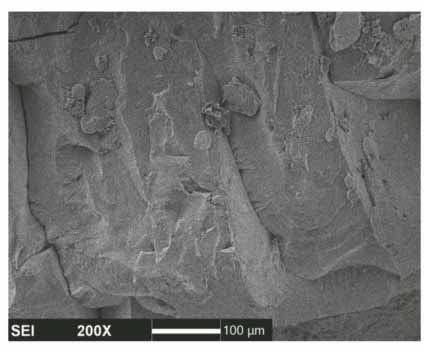

图 7. 基于Ti-Ni-Nb焊料的Ti3Al/GH4169 激光焊接头拉伸断口的SEM照片

Fig. 7. SEM image of tensile fracture of laser welded Ti3Al/GH4169 joint with Ti-Ni-Nb as filling material

下载图片 查看原文

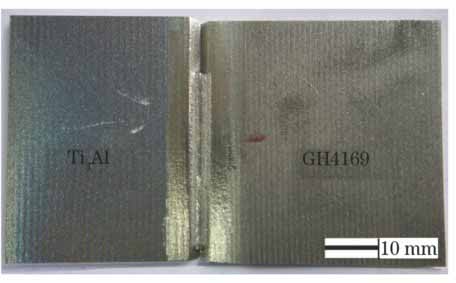

图 8. 基于Ti-Nb/Ti-Ni-Nb/Ni-Cu焊料的Ti3Al/GH4169激光焊接头的实物照片

Fig. 8. Photograph of laser welded Ti3Al/GH4169 joint with Ti-Nb/Ti-Ni-Nb/Ni-Cu as filling material

下载图片 查看原文

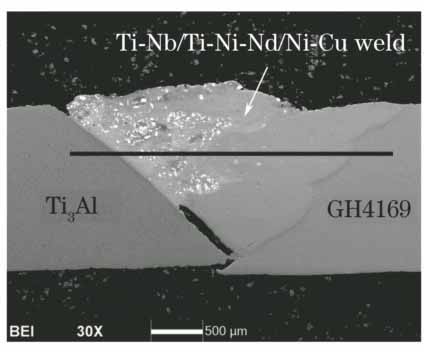

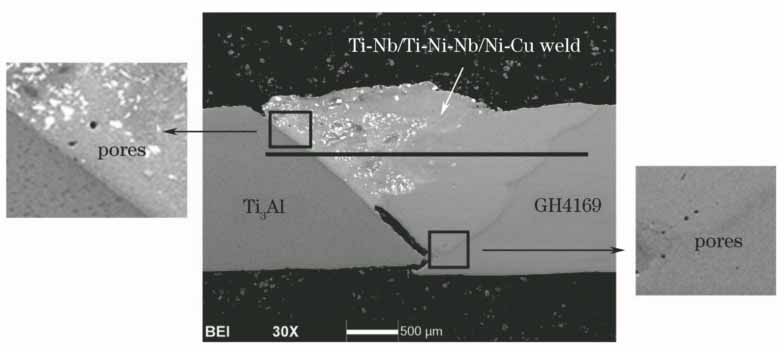

图 9. 基于Ti-Nb/Ti-Ni-Nb/Ni-Cu焊料的Ti3Al/GH4169激光焊接头截面的BSE照片

Fig. 9. Cross sectional BSE image of laser welded Ti3Al/GH4169 joint with Ti-Nb/Ti-Ni-Nb/Ni-Cu as filling material

下载图片 查看原文

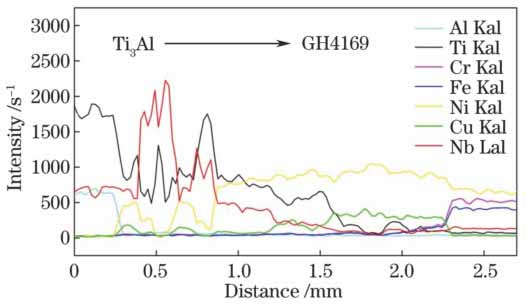

图 10. 基于Ti-Nb/Ti-Ni-Nb/Ni-Cu焊料的 Ti3Al/GH4169激光焊接头截面的线扫描结果

Fig. 10. Cross-sectional line scanning result of laser welded Ti3Al/GH4169 joint with Ti-Nb/Ti-Ni-Nb/Ni-Cu as filling material

下载图片 查看原文

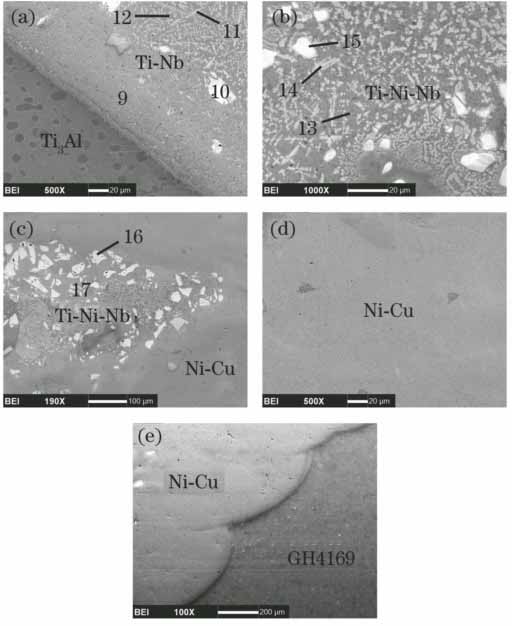

图 11. 基于Ti-Nb/Ti-Ni-Nb/Ni-Cu焊料的Ti3Al/GH4169 激光焊接头截面的微观组织。(a) Ti3Al/Ti-Nb界面;(b) Ti-Ni-Nb区;(c) Ti-Ni-Nb/Ni-Cu界面;(d) Ni-Cu区;(e) Ni-Cu/GH4169界面

Fig. 11. Cross sectional microstructures of laser welded Ti3Al/GH4169 joint with Ti-Nb/Ti-Ni-Nb/Ni-Cu as filling material. (a) Ti3Al/Ti-Nb interface; (b) Ti-Ni-Nb region; (c) Ti-Ni-Nb/Ni-Cu interface; (d) Ni-Cu region;(e) Ni-Cu/GH4169 interface

下载图片 查看原文

图 12. Ti3Al/GH4169激光焊接头中的气孔

Fig. 12. Pores in laser welded Ti3Al/GH4169 joint

下载图片 查看原文

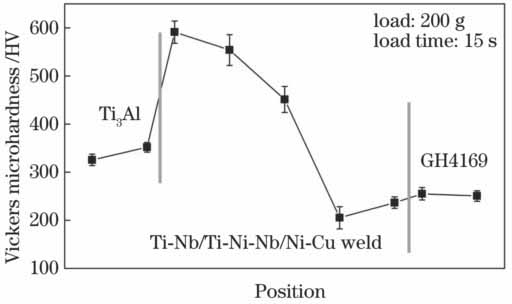

图 13. 基于Ti-Nb/Ti-Ni-Nb/Ni-Cu焊料的Ti3Al/GH4169 激光焊接头的显微硬度分布

Fig. 13. Micro-hardness distribution in laser welded Ti3Al/GH4169 joint with Ti-Nb/Ti-Ni-Nb/Ni-Cu as filling material

下载图片 查看原文

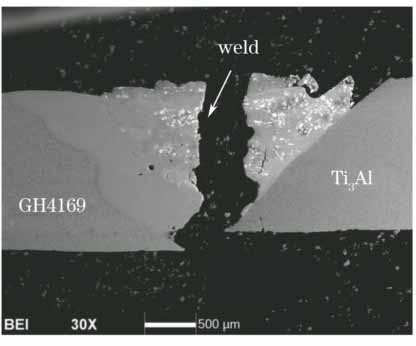

图 14. 基于Ti-Nb/Ti-Ni-Nb/Ni-Cu焊料的 Ti3Al/GH4169激光焊接头的断裂截面BSE照片

Fig. 14. Cross sectional BSE image of fracture of laser welded Ti3Al/GH4169 joint with Ti-Nb/Ti-Ni-Nb/Ni-Cu as filling material

下载图片 查看原文

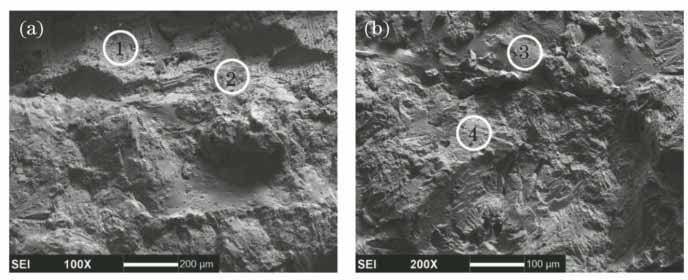

图 15. 基于Ti-Nb/Ti-Ni-Nb/Ni-Cu焊料的Ti3Al/GH4169激光焊接头的拉伸断口SEM照片

Fig. 15. SEM images of tensile fracture of laser welded Ti3Al/GH4169 joint with Ti-Nb/Ti-Ni-Nb/Ni-Cu as filling material

下载图片 查看原文

表 10 基于Ti-Nb/Ti-Ni-Nb/Ni-Cu焊料的Ti3Al/GH4169激光焊接头的拉伸断口的XEDS分析结果

Table1. 0 XEDS analysis results of tensile fracture of laser welded Ti3Al/GH4169 joint with Ti-Nb/Ti-Ni-Nb/Ni-Cu as filling material

| Position | Atomic fraction /% |

|---|

| Ti | Al | Ni | Nb | Cu | Fe | Cr |

|---|

| ① | 12.1 | 3.4 | 51.3 | 5.2 | 20.9 | 3.5 | 3.6 | | ② | 5.6 | 5.0 | 58.3 | 2.7 | 21.4 | 3.3 | 3.7 | | ③ | 30.8 | - | 53.5 | 11.9 | 3.1 | 0.3 | 0.4 | | ④ | 25.5 | - | 51.7 | 15.5 | 7.3 | - | - |

|

查看原文

表 1GH4169合金的化学成分(质量分数,%)

Table1. Chemical compositions of GH4169 alloy (mass fraction, %)

| Composition | Ti | Al | Ni | Cr | Mo | Nb | Fe |

|---|

| Value | 0.75-1.15 | 0.30-0.70 | 50.0-55.0 | 17.0-21.0 | 2.80-3.30 | 4.75-5.50 | Bal. |

|

查看原文

表 2激光焊接用焊料的化学成分(质量分数,%)

Table2. Chemical compositions of filling materials for laser welding (mass fraction, %)

| Filling material | Ti | Ni | Nb | Cu |

|---|

| Ti-Nb | 37 | 48 | 15 | - | | Ti-Ni-Nb | 40 | - | 60 | - | | Ni-Cu | - | 70 | - | 30 |

|

查看原文

表 3以Ti-Ni-Nb为焊料的Ti3Al/GH4169激光焊接的工艺参数

Table3. Process parameters in laser welding of Ti3Al/GH4169 with Ti-Ni-Nb as filling material

| Filling material | Laserpower /W | Scanning speed /(mm·min-1) | Protective gasflow /(L·min-1) | Layerheight /mm | Spotdiameter /mm |

|---|

| Ti-Ni-Nb | 270-350 | 500-650 | 25-35 | 0.2-0.3 | 0.6-1.5 |

|

查看原文

表 4基于Ti-Nb/Ti-Ni-Nb/Ni-Cu焊料的Ti3Al/GH4169激光焊接工艺参数

Table4. Process parameters in laser welding of Ti3Al/GH4169 with Ti-Nb/Ti-Ni-Nb/Ni-Cu as filling material

| Filling material | Laserpower /W | Scanning speed /(mm·min-1) | Protective gasflow /(L·min-1) | Layerheight /mm | Spotdiameter /mm |

|---|

| Ni-Cu | 200-280 | 450-550 | 20-30 | 0.3-0.5 | 0.6-1.5 | | Ti-Nb | 240-320 | 500-600 | 20-30 | 0.3-0.5 | 0.6-1.5 | | Ti-Ni-Nb | 270-350 | 500-650 | 25-35 | 0.3-0.5 | 0.6-1.5 |

|

查看原文

表 5基于Ti-Ni-Nb焊料的Ti3Al/GH4169激光焊接头中典型相的化学成分及推测相

Table5. Chemical compositions of typical phases in laser welded Ti3Al/GH4169 joint with Ti-Ni-Nb as filling material and the corresponding deduced phases

| Position | Atomic fraction /% | Deduced phase |

|---|

| Ti | Al | Ni | Nb | Fe | Cr |

|---|

| 1 | 52.5 | 1.7 | 27.0 | 15.2 | 1.9 | 1.7 | Ti-Ni-Nb alloy | | 2 | 43.1 | 1.3 | 17.0 | 35.3 | 1.8 | 1.5 | Nb, Ti solid solution | | 3 | 14.4 | - | 2.2 | 83.4 | - | - | Nb | | 4 | 51.5 | - | 34.5 | 14.0 | - | - | Ti-Ni-Nb alloy | | 5 | 26.9 | - | 8.8 | 64.3 | - | - | Nb, Ti solid solution | | 6 | 0.3 | - | - | 99.7 | - | - | Nb | | 7 | 56.6 | - | 32.1 | 11.3 | - | - | Ti-Ni-Nb alloy | | 8 | - | - | 0.8 | 99.2 | - | - | Nb |

|

查看原文

表 6基于Ti-Ni-Nb焊料的Ti3Al/GH4169激光焊接头的室温抗拉强度

Table6. Tensile strength at room temperature of laserwelded Ti3Al/GH4169 joint with Ti-Ni-Nb as filling material

| Experiment No. | 1 | 2 | 3 |

|---|

| Value /MPa | 102 | 154 | 132 | | Average value /MPa | 129 |

|

查看原文

表 7基于Ti-Ni-Nb焊料的Ti3Al/GH4169激光焊接头拉伸断口的XEDS分析结果

Table7. XEDS analysis results of tensile fracture of laser welded Ti3Al/GH4169 joint with Ti-Ni-Nb as filling material

| Item | Atomic fraction /% | Deduced phase |

|---|

| Ti | Al | Ni | Nb | Fe | Cr |

|---|

| Content | 32.2 | 0.7 | 44.3 | 18.2 | 1.7 | 2.9 | Ti-Ni-Nb alloy |

|

查看原文

表 8基于Ti-Nb/Ti-Ni-Nb/Ni-Cu焊料的Ti3Al/GH4169激光焊接头中典型相的化学成分及推测相

Table8. Chemical compositions of typical phases in laser welded Ti3Al/GH4169 joint with Ti-Nb/Ti-Ni-Nb/Ni-Cu as filling material and the corresponding deduced phases

| Position | Atomic fraction /% | | Deduced phase |

|---|

| Ti | | Al | Ni | Cu | Nb | Fe | Cr |

|---|

| 9 | 53.5 | 1.5 | 8.2 | 3.8 | 32.1 | 0.4 | 0.5 | (Ti, Nb) solid solution | | 10 | / | / | 0.6 | / | 99.4 | / | / | Nb | | 11 | 49.5 | 1.5 | 7.6 | 4.3 | 35.9 | 1.2 | / | (Ti, Nb) solid solution | | 12 | 46.8 | 0.7 | 19.7 | 3.3 | 27.3 | 1.3 | 0.9 | Ti-Ni-Nb alloy | | 13 | 50.0 | / | 31.0 | 5.0 | 14.0 | / | / | Ti-Ni-Nb alloy | | 14 | 33.1 | / | 7.3 | 1.1 | 58.5 | / | / | (Ti, Nb) solid solution | | 15 | / | / | / | / | 100.0 | / | / | Nb | | 16 | / | / | / | / | 100.0 | / | / | Nb | | 17 | 69.5 | / | 0.9 | / | 29.6 | / | / | (Ti, Nb) solid solution |

|

查看原文

表 9基于Ti-Nb/Ti-Ni-Nb/Ni-Cu焊料的Ti3Al/GH4169 激光焊接头的室温抗拉强度

Table9. Tensile strength at room temperature of laser welded Ti3Al/GH4169 joint with Ti-Nb/Ti-Ni-Nb/Ni-Cu as filling material

| Experiment No. | 1 | 2 | 3 |

|---|

| Value | 172 | 174 | 196 | | Average value /MPa | 180 |

|

查看原文

陈冰清, 熊华平, 孙兵兵, 魏振伟, 李万青. Ti3Al/GH4169异种材料激光焊接头的组织及性能[J]. 中国激光, 2018, 45(4): 0402004. Chen Bingqing, Xiong Huaping, Sun Bingbing, Wei Zhenwei, Li Wanqing. Microstructures and Properties of Laser Welded Dissimilar Ti3Al/GH4169 Joints[J]. Chinese Journal of Lasers, 2018, 45(4): 0402004.

下载: 699次

下载: 699次