1. INTRODUCTION

Recently, magnetic field sensors have been widely investigated for applications in various fields such as aerospace, intelligent weapons, aviation, and controlled nuclear fusion [1]. Optical fiber sensors play an important role in magnetic field detection because of their advantages of small size, high sensitivity, short response time, and anti-electromagnetic interference [24" target="_self" style="display: inline;">–4]. Magnetic fluid (MF) is a kind of novel functional material that has many remarkable magneto-optical properties such as tunable refractive index (RI), Faraday effect, and birefringence effect [5,6]. These unique properties have been employed in numerous optical fiber sensors incorporating MFs such as fiber Bragg gratings [7,8], modal interferometers [911" target="_self" style="display: inline;">–11], photonic crystal fibers [12], and Fabry–Perot and Michelson [13] interferometers. The core-offset microfiber configuration is low cost and easy to fabricate, but it employs intensity demodulation that cannot ignore the power fluctuation of the optical source [1]. The single-mode fiber (SMF)–multimode fiber–SMF and the nonadiabatic fiber taper configurations demonstrate the magnetic field sensitivities of 0.905 and , respectively [10,14]. However, these sensors are based on the interaction between the weak evanescent field and an external MF that limits their sensitivity to magnetic field.

To overcome these issues, we present a Mach–Zehnder interferometer (MZI) combined with MF in twin-core fiber (TCF) for ultrasensitive magnetic field measurement. The sensor is fabricated by splicing a short section of TCF between two SMFs and then drilling a microchannel through one core of TCF by use of a femtosecond laser. The microchannel is then filled with MF and the TCF region is sealed by a capillary tube. Based on the tunable RI property of MF, the RI difference between the medium and the pristine core will be changed with the variation of external magnetic field. This sensor exhibits an ultrahigh magnetic field sensitivity of 20.8 nm/mT from 5 to 9.5 mT, which, to the best of our knowledge, is the highest sensitivity among the reported magnetic field sensors and might be used for weak magnetic field detection.

2. OPERATING PRINCIPLE AND FABRICATION

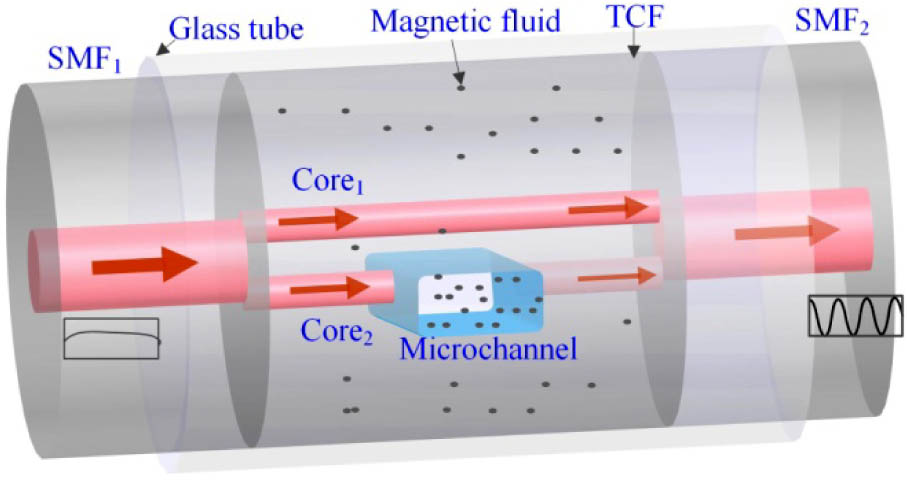

The schematic diagram of the proposed magnetic field sensor is illustrated in Fig. 1. The sensor is made up of a short section of TCF being spliced between two SMFs, and . The two splicing joints operate as optical splitter and combiner, respectively. The light propagating along is equally coupled to two cores of TCF at the left splicing joint. However, the light propagating through the micromachined core will be uniquely affected by the interposed medium, which induces a phase shift relative to light propagating along the pristine core. The shape of the two TCF cores is an asymmetric ellipse, and the TCF length is so that the light cross talk between the two cores can be negligible. Light propagation through the two cores can be reasonably assumed to be independent. Finally, two output beams are recoupled into at the right splicing joint.

Fig. 1. Schematic diagram of the proposed magnetic field sensor.

下载图片 查看所有图片

When two output beams, and , propagating through their respective cores of the TCF are recombined in , the phase difference between the two output beams results in interference. The interference intensity of the MZI can be expressed as where is the wavelength; is the length of the microchannel with respect to the propagation path; is the effective RI difference between the two interference arms, where and are the effective RI of the core and the medium in the microchannel; and is the initial phase of the interferometer. According to Eq. (1), the output intensity attains the minimum value under the following conditions: where is an integer and is the wavelength of the th order fringe dip. Here, the fringe means the interference spectrum. The free spectral range (FSR) of the fiber interferometer can be expressed as

When the effective RI of the medium in the microchannel is changed, will be changed and the th attenuation dip will be shifted by the amount , estimated as

The RI of MF is a function of the magnitude of the surrounding magnetic field. The spectrum of MF-based MZI will also be changed with variation of the surrounding magnetic field.

In this configuration, the SMF is Corning SMF-28 with core/cladding diameter of 8/125 μm, and TCF is supplied by Prof. Dong’s group in Xiamen University. Figure 2(a) shows the cross section of two fibers and the morphology of the splicing joint. Here, the cladding diameter of TCF is 125 μm and the length of major/minor axes of the two elliptical cores are and , respectively. The sensor fabrication involves two steps. First, the left end of TCF is spliced with by use of a commercial fusion splicer (Fujikura FSM-60s). To guarantee equal light intensity sent into the two cores, the offset distance between and TCF should be carefully adjusted by comparing the light intensity of the two cores of TCF when a red laser beam is launched into . Next, the TCF is cut off with a remaining length of ; then the right end of TCF is spliced with by an optimized offset value to obtain a maximum fringe visibility.

Fig. 2. (a) Optical microscope image of the cross-sectional morphology of SMF and TCF, including the dimensions of the elliptical TCF cores and the splicing point between and TCF. (b) Schematic diagram of the femtosecond laser micromachining system. The insert image shows an optical microscope image of the drilled microchannel through .

下载图片 查看所有图片

Second, a femtosecond laser (Spectra-Physics Solstice, 120 fs, 800 nm, 1 kHz, 4 mJ) is employed to drill the microchannel through the cladding and of TCF. A schematic diagram of the femtosecond laser micromachining system is shown in Fig. 2(b). The laser beam passes through an attenuator made up of a half-wave plate () and polarizer () for adjusting the laser power in the range from 0 to 4 mJ, is reflected by the beam splitter (BS), and is then focused onto the fiber by an objective lens (MO) with an NA value of 0.25. The average power of pulses prior to the MO is maintained at . The CCD camera allows for real-time monitoring of the micromachining process. The fiber is fixed in parallel with the axis of a computer-controlled 3D translation stage with a resolution of 10 nm. Fabrication of the microchannel is similar to that employed in a previously published procedure [15]. The microchannel is cleaned using alcohol after laser fabrication, and the completed microchannel is shown by the optical microscope image presented in Fig. 2(b). The relatively large surface roughness implies that the employed laser power was somewhat high. However, the processing parameters, including laser power and scanning speed, can be further optimized to obtain better surface quality.

The MF employed in this study consisted of magnetic particles with an average diameter around 10 nm dispersed in water. The TCF-based MZI configuration is inserted within a section of capillary tube having an interior diameter of 250 μm. The MF is injected through one port of the glass tube, and glue is applied to seal the device. Due to capillary action, the microchannel becomes fully filled with MF.

3. EXPERIMENTS AND RESULTS

The transmission spectra were measured during the overall fabrication process using a broadband light source (BBS) ranging from 1250 to 1650 nm and an optical spectrum analyzer (OSA) with a resolution of 0.05 nm, as indicated in Fig. 2(b). The black curve in Fig. 3 shows the transmission spectrum after splicing both SMFs with TCF, which indicates an absence of interference between light propagating through the separate cores. The two splicing joints between the SMFs and TCF cause an insertion loss of , whereas the cross talk between the two TCF cores is ignored, as discussed previously. The blue curve in Fig. 3 shows the transmission spectrum after completion of microchannel fabrication. Around 1563 nm, the fringe visibility and FSR are measured as and and the insertion loss is increased up to . Three factors may be responsible for this large insertion loss: (1) rough surface of the microchannel; (2) propagation loss of the unguided mode through the microchannel; and (3) connection loss at two splicing joints. By optimizing the machining parameters in fusion splicing and femtosecond laser micromachining, the insertion loss may be decreased to some degree. When the microchannel is filled with MF, there is only one fringe dip over the entire investigated wavelength range, as shown by the red curve of Fig. 3. According to Eq. (3), when the medium in the microchannel is changed to MF from air, the between the and MF will be sharply decreased, leading to the FSR being substantially increased so that only one fringe dip can be seen within the measured wavelength range.

Fig. 3. Transmission spectra of the pristine TCF and TCF with a microchannel filled with either air or an MF.

下载图片 查看所有图片

A schematic diagram of the magnetic field sensing is demonstrated in Fig. 4, where the magnetic field generator is formed by two electromagnets and a Gauss meter is employed for reference. The MF-filled fiber magnetic field sensor is placed parallel between the two electromagnets, and a BBS and an OSA are connected with the sensor to measure its transmission spectrum in real time. The magnetic field is given by the magnetic field generator with a stability of , which is increased from 0 to 36 mT in 2 mT intervals. The temperature is maintained at 25°C in this experiment.

Fig. 4. Schematic diagram of magnetic field response measurement.

下载图片 查看所有图片

The dependence of the wavelength of fringe dip on the magnitude of magnetic field for an MF-filled magnetic field sensor employing a microchannel with is presented in Fig. 5. It can be found that the fringe dip is nonlinearly shifted toward the longer wavelength with an increase of applied magnetic field. According to response sensitivity, its performance can be divided into four ranges, sluggish area (0–2 mT), high-sensitive area (2–12 mT), low-sensitive area (12–30 mT), and saturated area ().

Fig. 5. Variation of the fringe dip wavelength with respect to an applied magnetic field, divided into sluggish area, high-sensitive area, low-sensitive area, and saturated area.

下载图片 查看所有图片

The RI of MF can be expressed via the expression , where and are relative magnetic permeability and dielectric constant, respectively. When the MF is exposed to an external magnetic field, the ferromagnetic particles in the MF agglomerate and increasingly form magnetic columns, leading to phase separation and a resulting variation in the effective dielectric constant. As a result, the value of is altered. The effective dielectric constant is expressed as where represents the dielectric constant of a magnetic column, which is a constant; is the dielectric constant of the liquid phase, which varies according to the magnitude of the magnetic field; and , where represents the ratio of the area occupied by the magnetic columns to the total area, which is dependent on the magnitude of the external magnetic field. Hence, the can affect the . The magnetic permeability , where is the magnetic susceptibility depending on the magnitude of the magnetic field. The experimental result reveals that the value of depends on the magnitude of the magnetic field, which affects the value of , leading to a significant dip shift.

Studies have shown that the relationship between and applied magnetic field is an -type curve [14]. Because the magnetic particles are dispersed in water with a reckonable concentration and the initial magnetization, the value of changes little until the magnetic field exceeds the first critical point. When the magnetic field is further increased above the second critical point, the MF will become saturated, where the value of is hardly changed.

Another TCF-based MZI with the microchannel length of was fabricated to investigate its response over the linear range. The applied magnetic field was increased from 5 to 9.5 mT in intervals of 0.5 mT. The evolution of the transmission spectrum of the fiber magnetic field sensor as a function of magnetic field strength is presented in Fig. 6(a). The fringe dip is shifted to a longer wavelength with an increase of magnetic field strength. The relationship between dip wavelength and dip intensity and magnetic field strength are given in Fig. 6(b). They have good linear response for both cases with slopes of 20.8 nm/mT and .

Fig. 6. (a) Transmission spectral evolution with an increasing applied magnetic field in the linear response region from 5 to 9.5 mT. (b) Variation of the fringe dip wavelength and dip intensity with respect to an applied magnetic field.

下载图片 查看所有图片

The performance of other magnetic field sensors is compared with that of the proposed TCF-based MZI sensor, and the data is presented in Table 1. It can be seen that the magnetic field sensitivity of the TCF-based MZI sensor is by far the greatest among all sensors considered and was in some cases 2 orders of magnitude greater. In contrast to the structures of the other sensors, the TCF-based MZI employs an open MF-filled microchannel in which light can directly interact with MF in one of the interference arms of the MZI, which guarantees an ultrahigh magnetic field sensitivity.

Table 1. Comparisons of the Proposed TCF-Based MZI with Other Magnetic Field Sensors

| Structure | Range (mT) | Wavelength Sensitivity (nm/mT) | | Single-mode–multimode–single-mode [10] | 0–22 | 0.905 | | Asymmetric optical fiber taper [16] | 0–21.4 | −0.16206 | | Taper-like and lateral-offset fusion splicing [9] | 3.8–47.5 | 0.141 | | Michelson interferometer [13] | 0–107 | 0.0649 | | Fabry–Perot interferometer [6] | 0–40 | 0.431 | | Proposed MZI | 5–9.5 | 20.8 |

|

查看所有表

4. CONCLUSION

We have experimentally demonstrated an ultracompact TCF-based MZI for magnetic field measurement with extremely high sensitivity. The two cores of the TCF are employed as the two interference arms of the MZI, and an open microchannel was fabricated in one of the cores by means of femtosecond laser micromachining in which MF was filled, forming a direct component of the light propagation path. The resulting magnetic field sensor exhibits an ultrahigh sensitivity of 20.8 nm/mT with a range from 5.0 to 9.5 mT, which, to the best of our knowledge, is the highest sensitivity compared with all other reported magnetic field sensors. This sensor might be used in weak magnetic field detection.

Zhengyong Li, Changrui Liao, Jun Song, Ying Wang, Feng Zhu, Yiping Wang, Xiaopeng Dong. Ultrasensitive magnetic field sensor based on an in-fiber Mach–Zehnder interferometer with a magnetic fluid component[J]. Photonics Research, 2016, 4(5): 05000197.

Download: 1188次

Download: 1188次