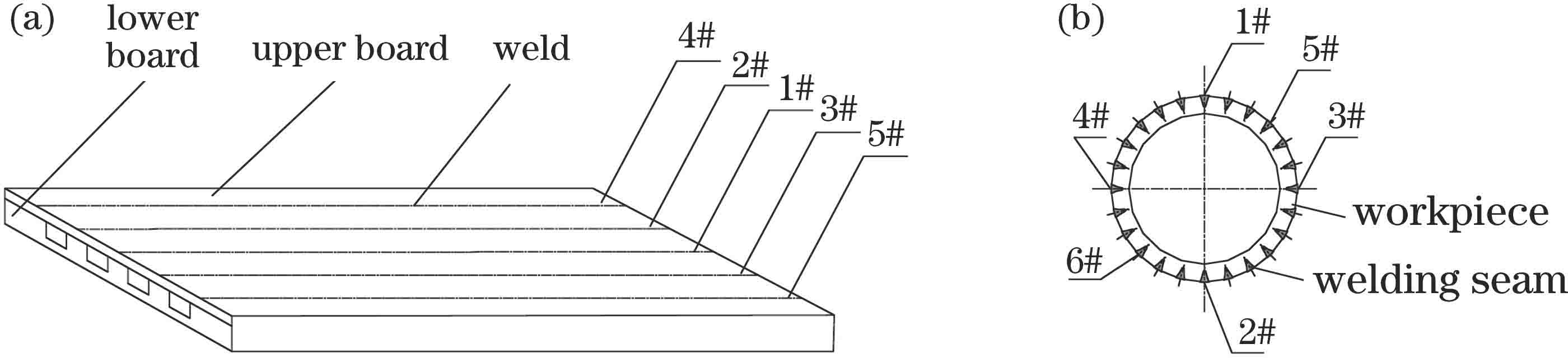

薄壁结构激光焊接随焊高频冲击变形控制  下载: 824次

下载: 824次

曹政, 姜仁杰, 杜伟哲, 武强, 肖荣诗. 薄壁结构激光焊接随焊高频冲击变形控制[J]. 中国激光, 2020, 47(9): 0902003.

Cao Zheng, Jiang Renjie, Du Weizhe, Wu Qiang, Xiao Rongshi. Distortion Control by In-site High Frequency Peening in Laser Welding of Thin-Walled Structures[J]. Chinese Journal of Lasers, 2020, 47(9): 0902003.

[1] Zhu Y H, Peng W, Xu R N, et al. Review on active thermal protection and its heat transfer for airbreathing hypersonic vehicles[J]. Chinese Journal of Aeronautics, 2018, 31(10): 1929-1953.

[2] 王继明, 李俐群, 彭根琛, 等. 10Ni5CrMoV钢真空激光焊接焊缝的组织与性能[J]. 中国激光, 2019, 46(4): 0402005.

[3] 赵乐, 韩雪, 邹江林, 等. 光纤激光深熔焊接小孔形成过程的研究[J]. 激光与光电子学进展, 2020, 57(7): 071402.

[4] 杜伟哲, 黄婷, 曹政, 等. AISI304不锈钢箔振镜扫描激光微焊接工艺[J]. 中国激光, 2019, 46(11): 1102006.

[5] Khurshid M, Leitner M, Barsoum Z, et al. Residual stress state induced by high frequency mechanical impact treatment in different steel grades:numerical and experimental study[J]. International Journal of Mechanical Sciences, 2017, 123: 34-42.

[6] Wang Z, Lu Y, Sun G, et al. Effect of ultra-sonic peening on laser-arc hybrid welded NV E690 steel[J]. Journal of Laser Applications, 2018, 30(3): 032403.

[7] Yuan K L, Sumi Y. Simulation of residual stress and fatigue strength of welded joints under the effects of ultrasonic impact treatment (UIT)[J]. International Journal of Fatigue, 2016, 92: 321-332.

[8] Shalvandi M, Hojjat Y, Abdullah A, et al. Influence of ultrasonic stress relief on stainless steel 316 specimens:a comparison with thermal stress relief[J]. Materials & Design, 2013, 46: 713-723.

[9] Li N, Sun J, Zhang G, et al. Effect of ultrasonic impact peening on Ti-6Al-4V laser deposition shaping[J]. Journal of Laser Applications, 2017, 29(2): 022505.

[10] 曲宏韬. 随焊超声冲击设备的研制及超声冲击作用机理研究[D]. 哈尔滨: 哈尔滨工业大学, 2014.

Qu HT. Investigation of ultrasonic impact equipment during welding and study on ultrasonic impact effect[D]. Harbin: Harbin Institute of Technology, 2014.

[11] 陈琪昊, 林三宝, 杨春利, 等. 随焊超声冲击对2A14铝合金TIG焊接接头显微组织和力学性能的影响[J]. 中国有色金属学报, 2016, 26(10): 2071-2077.

Chen Q H, Lin S B, Yang C L, et al. Effect of ultrasonic impact during welding on microstructures and mechanical properties of TIG welded joint of 2A14 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(10): 2071-2077.

[12] 赵维. 实时超声冲击消减焊接残余应力及变形的实验和仿真研究[D]. 哈尔滨: 哈尔滨工业大学, 2017.

ZhaoW. Experimental and simulation study on eliminating welding residual stress and deformatiaon by real time ultrasonic impact treament[D]. Harbin: Harbin Institute of Technology, 2017.

[13] 梁行, 阚盈, 姜云禄, 等. 不锈钢薄板激光搭接焊接头的力学性能[J]. 中国激光, 2018, 45(6): 0602001.

[14] 余霞, 罗佳琪, 肖晓晟, 等. 高功率超快光纤激光器研究进展[J]. 中国激光, 2019, 46(5): 0508007.

[15] 刘恩泽, 姚成武, 谢雨凌, 等. 非熔透激光搭接焊SUS304奥氏体不锈钢无焊缝侧变形机理[J]. 中国激光, 2019, 46(4): 0402002.

[16] 李祚, 隋尚, 袁子豪, 等. 高沉积率激光熔覆沉积GH4169合金的微观组织与拉伸性能[J]. 中国激光, 2019, 46(1): 0102004.

[17] Fahlström K, Andersson O, Melander A, et al. Correlation between laser welding sequence and distortions for thin sheet structures[J]. Science and Technology of Welding and Joining, 2017, 22(2): 150-156.

曹政, 姜仁杰, 杜伟哲, 武强, 肖荣诗. 薄壁结构激光焊接随焊高频冲击变形控制[J]. 中国激光, 2020, 47(9): 0902003. Cao Zheng, Jiang Renjie, Du Weizhe, Wu Qiang, Xiao Rongshi. Distortion Control by In-site High Frequency Peening in Laser Welding of Thin-Walled Structures[J]. Chinese Journal of Lasers, 2020, 47(9): 0902003.