纳米TiC改性对选区激光熔化铜成形的影响  下载: 905次

下载: 905次

Objective With its excellent thermal conductivity, copper is an ideal material for the critical complex cooling parts in the combustion chambers of aerospace engines. Increasingly, complex copper parts are being fabricated by selective laser melting, an additive manufacturing method that forms complex 3D parts and structures. However, bulk copper surfaces and spherical copper particles absorb less than 10% and 45% of 1064 nm laser energy, respectively. Melting the copper powder completely and fabricating sound copper parts without defects such as unmelted particles and holes are difficult tasks. Recently, we improved the laser absorptivity of copper powder by nano-TiC modification, and fabricated a sample with a density of 99.8% under a 1064 nm laser (340 W, 500 mm/s). Our modification technique provides a novel solution to the above problem.

Methods The reflectivities of nano-TiC, unmodified pure copper powder, and copper powder modified with 0.2%(mass fraction) nano-TiC were measured under lasers of different wavelengths. Measurements were performed in a UV-3600 plus ultraviolet spectrophotometer. The morphologies of the powders and nano-TiC particles were observed by scanning electron microscopy with energy-dispersive X-ray spectroscopy. The unmodified and modified copper powders were subjected to selective laser melting in a metal 3D printer (EOS M290) operated with a 400 W and 1064 nm laser under the same scanning conditions (340 W, 500 mm/s). The relative densities of the samples were determined by the Archimedes method. Their morphologies and hardness values were analyzed by a Nikon optical microscope and a Brinell hardness tester, respectively. The thermal and electrical conductivities of the samples were measured by a laser thermal conductivity meter and a Hall effect tester, respectively.

Results and Discussions The observation and analyses confirmed that: a) modifying the copper powder with 0.2% nano-TiC significantly reduced the reflectivity of copper to 1064 nm laser, and consequently increased the laser absorptivity from 22% to 53.7% (Fig. 4); b) the sample modified with the powder had a much higher relative density (99.8%) and significantly fewer defects than the sample fabricated from unmodified pure copper powder under the same conditions (340 W, 500 mm/s) (Fig. 5); c) modification with nano-TiC improved the Brinell hardness of the samples from 64.5 to 87.7 HB (Fig. 6); d) the modification improved the thermal and electrical conductivities of the samples from 120.8 W/(m·K) and 29.1% IACS, respectively, to 189.2 W/(m·K) and 42.1% IACS, respectively. The improved relative density fundamentally improved the performance of the samples.

Conclusions The proposed modification increased the relative density of copper powder from 90.7% to 99.8% and improved its laser absorptivity from 22% to 53.7% under a 1064 nm laser (340 W, 500 mm/s). The high relative density correspondingly improved the Brinell hardness, thermal conductivity, and electrical conductivity of the modified sample. Modification by nano-TiC is a novel and effective technique for increasing the laser absorptivity of copper and fabricating high-density copper parts by selective laser melting under low-power laser scanning.

选区激光熔化是一种根据零件三维数字模型的离散数据,用聚焦激光束逐点选择性熔化金属粉末,逐层凝固堆积制造零件的一种近净成形增材制造方法[1]。这一方法能方便地实现复杂零件的高精度成形,为航天发动机燃烧室的结构设计及优化提供了一种新途径[2]。

铜的导热性能优良,是制造航天发动机燃烧室冷却壁等的理想材料[3]。然而,铜对激光的吸收率低,块体铜表面对选区激光熔化常用的1064 nm激光的吸收率低于10%,球形铜粉末对1064 nm激光的吸收率受粉末粒径的影响,一般在45%以下。这导致在选区激光熔化过程中铜粉难以完全熔化,从而出现未熔、孔洞、裂纹等缺陷,难以获得高致密度的成形件[4-7]。Ikeshoji等[8]使用大功率1064 nm激光器在激光功率为800 W、扫描速率为300 mm/s的条件下获得了致密度为96.6%的纯铜试样,但铜对激光的高反射使成形过程中的激光器极易损坏[9]。如何提高铜对激光能量的吸收,实现高致密度成形件的制备,是目前选区激光熔化铜3D打印的热点与难点[7,10]。最近,本课题组通过采用微量纳米TiC对铜粉进行改性来提高铜粉对激光的吸收率,在较低激光功率下获得了致密度为99.8%的试样,为解决这一问题提供了新的途径。

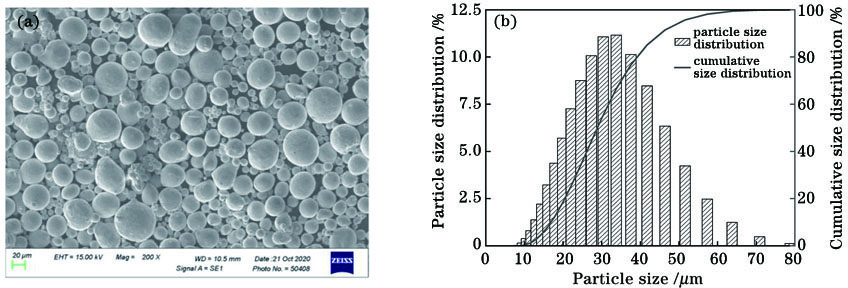

图 1. 15~53 μm球形铜粉的形貌和粒径分布。(a)形貌;(b)粒径分布

Fig. 1. Morphology and particle size distribution of 15-53 μm spherical copper powder. (a) Morphology; (b) size distribution

图 3. 改性铜粉的形貌和EDS面扫描结果。(a)形貌;(b) EDS面扫描结果

Fig. 3. Morphology and EDS result of nano-TiC modified copper powder. (a) Morphology; (b) EDS result

图 4. 纳米TiC、未改性铜粉和纳米TiC改性铜粉的反射率

Fig. 4. Reflectivity of nano-TiC, copper powder and nano-TiC modified copper powder

图 5. 未改性铜粉与纳米TiC改性铜粉成形试样在腐蚀前的形貌。(a) 未改性铜粉成形试样;(b) 纳米TiC改性铜粉成形试样

Fig. 5. Morphologies of formed samples with copper powder and nano-TiC modified copper powder before corrosion. (a) Formed sample with copper; (b) formed sample with nano-TiC modified copper

采用HBE-3000A型电子布氏硬度计(硬质合金球压头的直径为2.5 mm)测试试样的硬度,结果表明,在加载载荷为612.9 N、保压时间为30 s的条件下,改性铜粉成形试样的硬度达到了87.7 HB,远高于未改性铜粉成形试样的硬度(64.5 HB)。

纳米TiC改性对激光吸收率和成形试样致密度、硬度的影响如

图 6. 纳米TiC改性对激光吸收率以及成形试样致密度、硬度的影响

Fig. 6. Effect of nano-TiC modification on laser absorptivity of copper powder, density and hardness of selective laser melted sample

由

使用耐驰LFA457激光热导仪对TiC改性前后试样的导热性能进行了初步研究,结果表明,改性前试样的热导率为120.8 W/(m·K),改性后试样的热导率为189.2 W/(m·K)。使用霍尔效应测试仪对TiC改性前后试样的导电率进行了初步研究,结果表明,改性前试样的导电率为29.1%IACS,改性后试样的导电率为42.1% IACS。这说明致密度是影响成形试样的导电性能和导热性能的主要因素。

[1] 田健, 魏青松, 朱文志, 等. Cu-Al-Ni-Ti合金激光选区成形工艺及其力学性能[J]. 中国激光, 2019, 46(3): 0302001.

[2] 顾冬冬, 张红梅, 陈洪宇, 等. 航空航天高性能金属材料构件激光增材制造[J]. 中国激光, 2020, 47(5): 0500002.

[3] 左蔚, 宋梦华, 杨欢庆, 等. 增材制造技术在液体火箭发动机应用述评[J]. 火箭推进, 2018, 44(2): 55-65.

Zuo W, Song M H, Yang H Q, et al. Application of additive manufacturing technology in liquid rocket engine[J]. Journal of Rocket Propulsion, 2018, 44(2): 55-65.

[4] Colopi M, Caprio L, Demir A G, et al. Selective laser melting of pure Cu with a 1 kW single mode fiber laser[J]. Procedia CIRP, 2018, 74: 59-63.

[5] 严深平, 张安峰, 梁少端, 等. 激光增材制造技术常用金属材料激光吸收率测量[J]. 航空制造技术, 2017, 60(17): 97-100.

[6] 周燕, 陈柯宇, 文世峰, 等. 激光选区熔化成形纯铜的工艺及其性能研究[J]. 应用激光, 2019, 39(3): 387-393.

[9] Jadhav S D, Dadbakhsh S, Goossens L, et al. Influence of selective laser melting process parameters on texture evolution in pure copper[J]. Journal of Materials Processing Technology, 2019, 270: 47-58.

[10] 杨永强, 吴世彪, 张越, 等. 光纤激光器在金属增材制造中的应用进展及展望[J]. 中国激光, 2020, 47(5): 0500012.

黎振华, 申继标, 李淮阳, 滕宝仁, 刘静. 纳米TiC改性对选区激光熔化铜成形的影响[J]. 中国激光, 2021, 48(3): 0315001. Zhenhua Li, Jibiao Shen, Huaiyang Li, Baoren Teng, Jing Liu. Effect of Nano-TiC Modification on Selective Laser Melting of Copper[J]. Chinese Journal of Lasers, 2021, 48(3): 0315001.