[1] 徐滨士, 李恩重, 郑汉东, 等. 我国再制造产业及其发展战略[J]. 中国工程科学, 2017, 19(3): 61-65.

Xu B S, Li E Z, Zheng H D, et al. The remanufacturing industry and its development strategy in China[J]. Engineering Science, 2017, 19(3): 61-65.

[2] Wei S G, Cheng D B, Sundin E, et al. Motives and barriers of the remanufacturing industry in China[J]. Journal of Cleaner Production, 2015, 94: 340-351.

[3] 封慧, 李剑峰, 孙杰. 曲轴轴颈损伤表面的激光熔覆再制造修复[J]. 中国激光, 2014, 41(8): 0803003.

Feng H, Li J F, Sun J. Study on remanufacturing repair of damaged crank shaft journal surface by laser cladding[J]. Chinese Journal of Lasers, 2014, 41(8): 0803003.

[4] Tseng W C, Aoh J N. Simulation study on laser cladding on preplaced powder layer with a tailored laser heat source[J]. Optics & Laser Technology, 2013, 48: 141-152.

[5] Li J Z, Li X F, Zuo D W, et al. Process test and temperature field simulation of the Al/Ti laser cladding coating above 7050 aluminum alloy[J]. Laser & Optoelectronics Progress, 2014, 51(12): 121403.

[6] Torres Cruz A, de Lange D F, Medellín-Castillo H I. Comparative study of numerical models of the laser forming process[J]. Journal of Laser Applications, 2015, 27(S2): S29105.

[7] Boutalbi N, Bouaziz M N, Allouche M. Influence of temperature-dependent absorptivity on solid surface heated by CO2 and Nd∶YAG lasers[J]. Journal of Laser Applications, 2016, 28(3): 032004.

[8] Farahmand P, Kovacevic R. An experimental-numerical investigation of heat distribution and stress field in single- and multi-track laser cladding by a high-power direct diode laser[J]. Optics & Laser Technology, 2014, 63: 154-168.

[9] Mirzade F K, Niziev V G, Panchenko V Y, et al. Kinetic approach in numerical modeling of melting and crystallization at laser cladding with powder injection[J]. Physica B: Condensed Matter, 2013, 423: 69-76.

[10] 李豪, 王彦芳, 石志强, 等. 基于椭圆热源模型的激光熔覆温度场与流场数值模拟[J]. 应用激光, 2017, 37(2): 218-222.

Li H, Wang Y F, Shi Z Q, et al. Simulation of laser cladding temperature field and flow field based on ellipse heat source model[J]. Applied Laser, 2017, 37(2): 218-222.

[11] 刘昊, 虞钢, 何秀丽, 等. 送粉式激光熔覆中瞬态温度场与几何形貌的三维数值模拟[J]. 中国激光, 2013, 40(12): 1203007.

Liu H, Yu G, He X L, et al. Three-dimensional numerical simulation of transient temperature field and coating geometry in powder feeding laser cladding[J]. Chinese Journal of Lasers, 2013, 40(12): 1203007.

[12] 宋建丽, 李永堂, 邓琦林, 等. 激光熔覆成形技术的研究进展[J]. 机械工程学报, 2010, 46(14): 29-39.

Song J L, Li Y T, Deng Q L, et al. Research progress of laser cladding forming technology[J]. Journal of Mechanical Engineering, 2010, 46(14): 29-39.

[13] 华亮, 田威, 廖文和, 等. 基于非线性连续疲劳损伤的激光熔覆构件疲劳寿命评估[J]. 中国激光, 2015, 42(9): 0903006.

Hua L, Tian W, Liao W H, et al. Fatigue life evaluation for laser cladding component based on non-linear continuum fatigue damage model[J]. Chinese Journal of Lasers, 2015, 42(9): 0903006.

[14] 李美艳, 蔡春波, 韩彬, 等. 预热对激光熔覆陶瓷涂层温度场和应力场影响[J]. 材料热处理学报, 2015, 36(12): 197-203.

Li M Y, Cai C B, Han B, et al. Numerical simulation of preheating on temperature and stress fields by laser cladding Ni-based ceramic coating[J]. Transactions of Materials and Heat Treatment, 2015, 36(12): 197-203.

[15] Liu Q C, Janardhana M, Hinton B, et al. Laser cladding as a potential repair technology for damaged aircraft components[J]. International Journal of Structural Integrity, 2011, 2(3): 314-331.

[16] 方金祥, 董世运, 徐滨士, 等. 考虑固态相变的激光熔覆成形应力场有限元分析[J]. 中国激光, 2015, 42(5): 0503009.

Fang J X, Dong S Y, Xu B S, et al. Study of stresses of laser metal deposition using FEM considering phase transformation effects[J]. Chinese Journal of Lasers, 2015, 42(5): 0503009.

[17] 戴德平, 蒋小华, 蔡建鹏, 等. 激光熔覆Inconel718镍基合金温度场与应力场模拟[J]. 中国激光, 2015, 42(9): 0903005.

Dai D P, Jiang X H, Cai J P, et al. Numerical simulation of temperature field and stress distribution in Inconel718 Ni base alloy induced by laser cladding[J]. Chinese Journal of Lasers, 2015, 42(9): 0903005.

[18] 中国航空材料手册编辑委员会.

中国航空材料手册[M].

2版. 北京:

中国标准出版社,

2002:

510-

526.

China Aeronautical Materials Handbook Editorial Committee.

China aeronautical materials handbook[M]. 2nd ed.

Beijing:

China Standard Press,

2002:

510-

526.

[19] 曹云龙.

316L不锈钢表面激光熔覆Co/稀土涂层组织与性能的研究[D].

吉林: 吉林大学,

2015:

37-

47.

Cao YL.

Research of microstructure and properties of laser cladding Co/RE on 316L stainless steel[D].

Jilin: Jilin University,

2015:

37-

47.

[20] 宫新勇,

高士友,

咸士玉,

等.

基于温度特征的单道激光熔覆翘曲变形[J]. 激光与光电子学进展,

2017(

10):

101410.

Gong XY,

Gao SY,

Xian SY, et al.

Warp deformation in single-track laser cladding based on temperature characteristics[J]. Laser & Optoelectronics Progress,

2017(

10):

101410.

[21] 李美艳, 韩彬, 蔡春波, 等. 36(5): 25-28[J]. . 激光熔覆镍基合金温度场和应力场数值模拟. 焊接学报, 2015, 32: 114.

Li M Y, Han B, Cai C B, et al. 36(5): 25-28[J]. stress fields of laser cladded Ni-based coating. Transactions of the China Welding Institution, 2015, 32: 114.

[22] 刘衍聪, 范常峰, 尹晓丽, 等. 铸铁表面双光束激光熔覆温度场与应力场分析[J]. 应用激光, 2014, 34(4): 288-293.

Liu Y C, Fan C F, Yin X L, et al. Temperature and stress analysis of dual-beam laser cladding on gray cast iron surface[J]. Applied Laser, 2014, 34(4): 288-293.

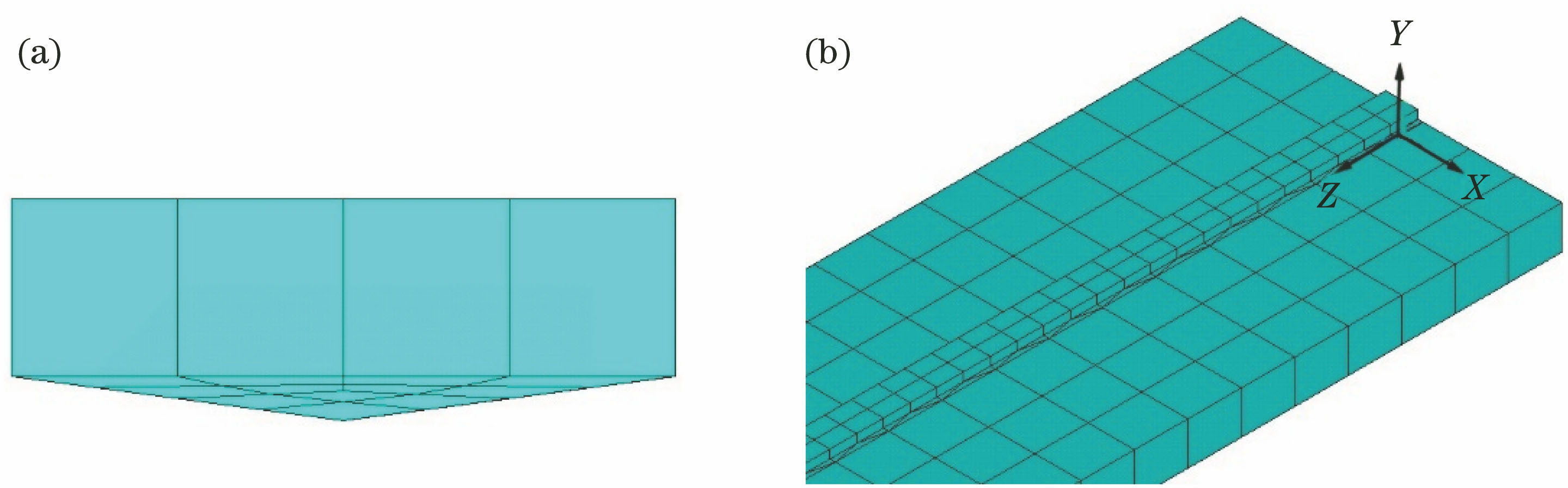

[23] 王凯, 赵剑峰, 潘浒, 等. 工件形状对镍基高温合金激光再制造应力场分布的影响[J]. 激光与光电子学进展, 2013, 50(4): 041402.

Wang K, Zhao J F, Pan H, et al. Influence of repair cross section on stress-field distribution in the nickel-based superalloy laser remanufacturing[J]. Laser & Optoelectronics Progress, 2013, 50(4): 041402.

[24] 吴晶. 辐射对流耦合换热过程性能优化准则分析[J]. 工程热物理学报, 2013, 34(10): 1922-1925.

Wu J. An analysis of performance optimization criteria for a coupled radiative-convective heat transfer process[J]. Journal of Engineering Thermophysics, 2013, 34(10): 1922-1925.

[25] 李松, 蔡翔, 朱路飞, 等. 基于单流道和结构网格的湿式潜水泵数值模拟[J]. 华东理工大学学报(自然科学版), 2016, 42(4): 580-586.

Li S, Cai X, Zhu L F, et al. Numerical simulation of wet submersible pump based on the single passage and structured grid[J]. Journal of East China University of Science and Technology (Natural Science Edition), 2016, 42(4): 580-586.

[26] 潘浒, 赵剑峰, 刘云雷, 等. 激光熔覆修复镍基高温合金稀释率的可控性研究[J]. 中国激光, 2013, 40(4): 0403007.

Pan H, Zhao J F, Liu Y L, et al. Controllability research on dilution ratio of nickel-based superalloy by laser cladding reparation[J]. Chinese Journal of Lasers, 2013, 40(4): 0403007.

[27] Kardas O O, Keles O, Akhtar S, et al. Laser cutting of rectangular geometry in 2024 aluminum alloy: thermal stress analysis[J]. Optics & Laser Technology, 2014, 64: 247-256.

下载: 1609次

下载: 1609次