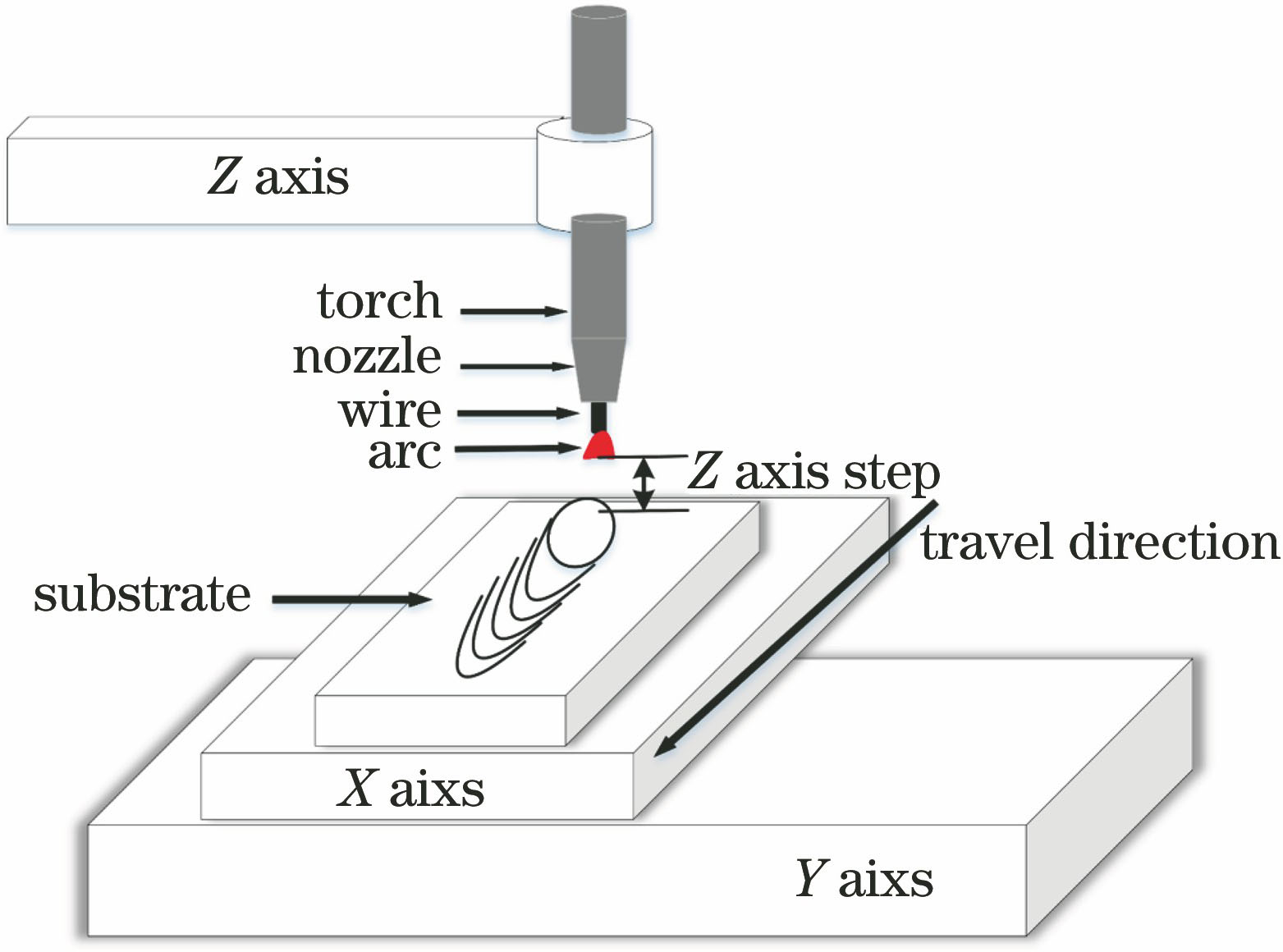

激光视觉传感系统的电弧增材制造侧表面成形分析  下载: 985次

下载: 985次

马波, 高向东, 黄怡洁, 张艳喜, 游德勇, 张南峰. 激光视觉传感系统的电弧增材制造侧表面成形分析[J]. 中国激光, 2019, 46(11): 1102005.

Bo Ma, Xiangdong Gao, Yijie Huang, Yanxi Zhang, Deyong You, Nanfeng Zhang. Side-Surface-Form Analysis of Arc Additive Manufacturing Based on Laser Vision Sensing System[J]. Chinese Journal of Lasers, 2019, 46(11): 1102005.

[1] 周祥曼, 田启华, 杜义贤, 等. 电弧增材成形单道两层熔积过程中的晶粒生长模拟[J]. 机械工程学报, 2018, 54(22): 86-94.

[2] 冯毅, 张鹏贤, 贾金龙. 近两年丝材+电弧增材制造研究进展[J]. 热加工工艺, 2018, 47(21): 23-26.

[3] 熊俊, 薛永刚, 陈辉, 等. 电弧增材制造成形控制技术的研究现状与展望[J]. 电焊机, 2015, 45(9): 45-50.

[4] 杨海欧, 王健, 周颖惠, 等. 电弧增材制造技术及其在TC4钛合金中的应用研究进展[J]. 材料导报, 2018, 32(11): 1884-1890.

[8] 高向东, 龙观富, 汪润林, 等. 大功率盘形激光焊飞溅特征分析[J]. 物理学报, 2012, 61(9): 098103.

[10] 黄怡洁, 高向东, 林少铎. 激光焊接参数对有机玻璃与不锈钢接头力学性能的影响[J]. 中国激光, 2017, 44(12): 1202006.

[11] 张斌, 常森, 王桔, 等. 基于遗传算法的激光视觉焊缝特征点提取[J]. 中国激光, 2019, 46(1): 0102001.

[12] 张鹏贤, 张国强, 韦志成, 等. 坡口及焊缝表面三维轮廓的激光视觉测量[J]. 焊接学报, 2017, 38(12): 85-89.

[14] 王文超, 高向东, 丁晓东, 等. 无坡口对接焊缝特征角点检测方法[J]. 焊接学报, 2018, 39(9): 61-64.

[15] CloudCompare. 3D point cloud and mesh processing software open source project[Z/OL]. [2019-05-01].http:∥www.danielgm.net/.

[16] 黄凯, 程效军, 贾东峰, 等. 一种密集管道点云数据自动分割算法[J]. 中国激光, 2018, 45(11): 1104004.

马波, 高向东, 黄怡洁, 张艳喜, 游德勇, 张南峰. 激光视觉传感系统的电弧增材制造侧表面成形分析[J]. 中国激光, 2019, 46(11): 1102005. Bo Ma, Xiangdong Gao, Yijie Huang, Yanxi Zhang, Deyong You, Nanfeng Zhang. Side-Surface-Form Analysis of Arc Additive Manufacturing Based on Laser Vision Sensing System[J]. Chinese Journal of Lasers, 2019, 46(11): 1102005.