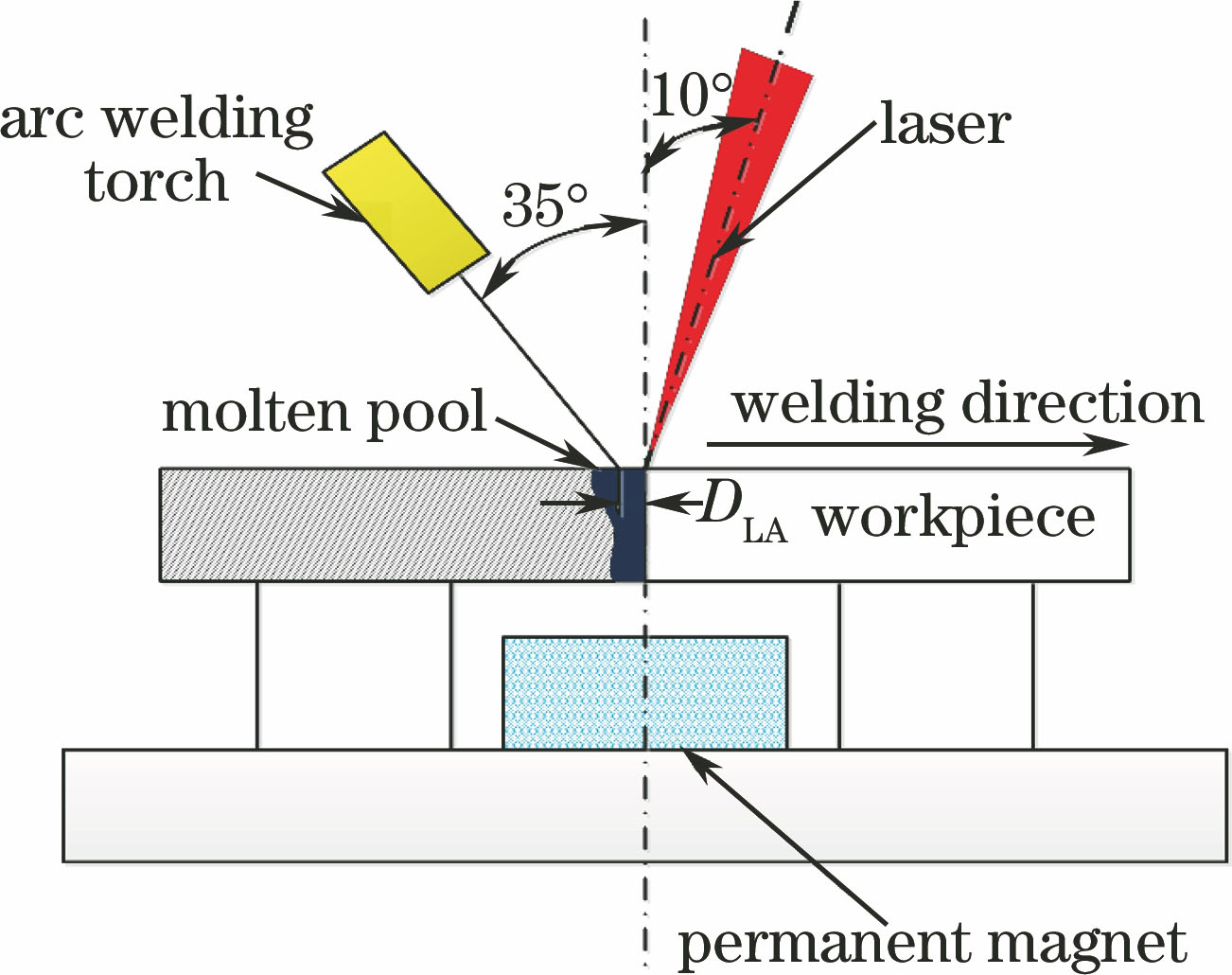

外加纵向磁场对激光-MIG复合焊接接头形貌及微观组织的影响  下载: 805次

下载: 805次

张勋, 李若杨, 赵泽洋, 米高阳, 王春明, 胡席远. 外加纵向磁场对激光-MIG复合焊接接头形貌及微观组织的影响[J]. 中国激光, 2017, 44(8): 0802008.

Zhang Xun, Li Ruoyang, Zhao Zeyang, Mi Gaoyang, Wang Chunming, Hu Xiyuan. Influence of External Longitudinal Magnetic Field on Weld Joint Morphology and Microstructure in Laser-Metal Inert Gas Hybrid Welding[J]. Chinese Journal of Lasers, 2017, 44(8): 0802008.

[1] Blinkov V A, Sheninkin M Z, Abralv M A. Grains of solidifying metal refined under vibrations[J]. Autom Weld, 1975, 28(11): 11-12.

[4] Mousavi M G. Hermans M J M, Richardson I M, et al. Grain refinement due to grain detachment in electromagnetically stirred AA7020 welds[J]. Science and Technology of Welding and Joining, 2003, 8(4): 309-312.

[7] 岳建锋, 李亮玉, 刘文吉, 等. 基于外加高频交变磁场下向MAG焊熔池成形控制[J]. 机械工程学报, 2013, 49(8): 65-70.

[9] ZhouJ, Tsai HL. Application of electromagnetic force in laser welding[C]. ASME International Mechanical Engineering Congress and Exposition, 2007, 8: 1025- 1030.

[10] 杨德才, 刘金和. 外加磁场对激光焊接熔深的影响[J]. 激光技术, 2001, 25(5): 347-350.

[11] 陈武柱, 彭云, 王成, 等. 激光焊接等离子体的扩散行为及电磁场对其作用的研究[J]. 中国激光, 2002, 29(s1): 529-531.

[14] 余圣甫, 张友寿, 雷毅, 等. 非磁性合金激光焊旋转磁场搅拌机理[J]. 焊接学报, 2006, 27(3): 109-112.

[16] 王维, 刘奇, 杨光, 等. 电磁搅拌作用下激光熔池电磁场、温度场和流场的数值模拟[J]. 中国激光, 2015, 42(2): 0202007.

[17] 宋诗英, 王梁, 胡勇, 等. 稳态磁场辅助激光熔注制备梯度涂层[J]. 中国激光, 2016, 43(5): 0503005.

[18] 王梁, 胡勇, 宋诗英, 等. 稳态磁场辅助对激光熔凝层表面波纹的抑制作用研究[J]. 中国激光, 2015, 42(11): 1103005.

[19] KouS. Welding metallurgy[M]. New Jersey: John Wiley and Sons, 2002: 294- 295.

[21] 赵博. 窄间隙MAG焊电弧行为研究[D]. 哈尔滨: 哈尔滨工业大学, 2009: 89- 94.

ZhaoBo. Research on arc behaviors of narrow-gap MAG[D]. Harbin: Harbin Institute of Technology, 2009: 89- 94.

[23] John CL, Damian JK. Welding metallurgy and weldability of stainless steels[M]. New Jersey: John Wiley and Sons, 2005.

张勋, 李若杨, 赵泽洋, 米高阳, 王春明, 胡席远. 外加纵向磁场对激光-MIG复合焊接接头形貌及微观组织的影响[J]. 中国激光, 2017, 44(8): 0802008. Zhang Xun, Li Ruoyang, Zhao Zeyang, Mi Gaoyang, Wang Chunming, Hu Xiyuan. Influence of External Longitudinal Magnetic Field on Weld Joint Morphology and Microstructure in Laser-Metal Inert Gas Hybrid Welding[J]. Chinese Journal of Lasers, 2017, 44(8): 0802008.