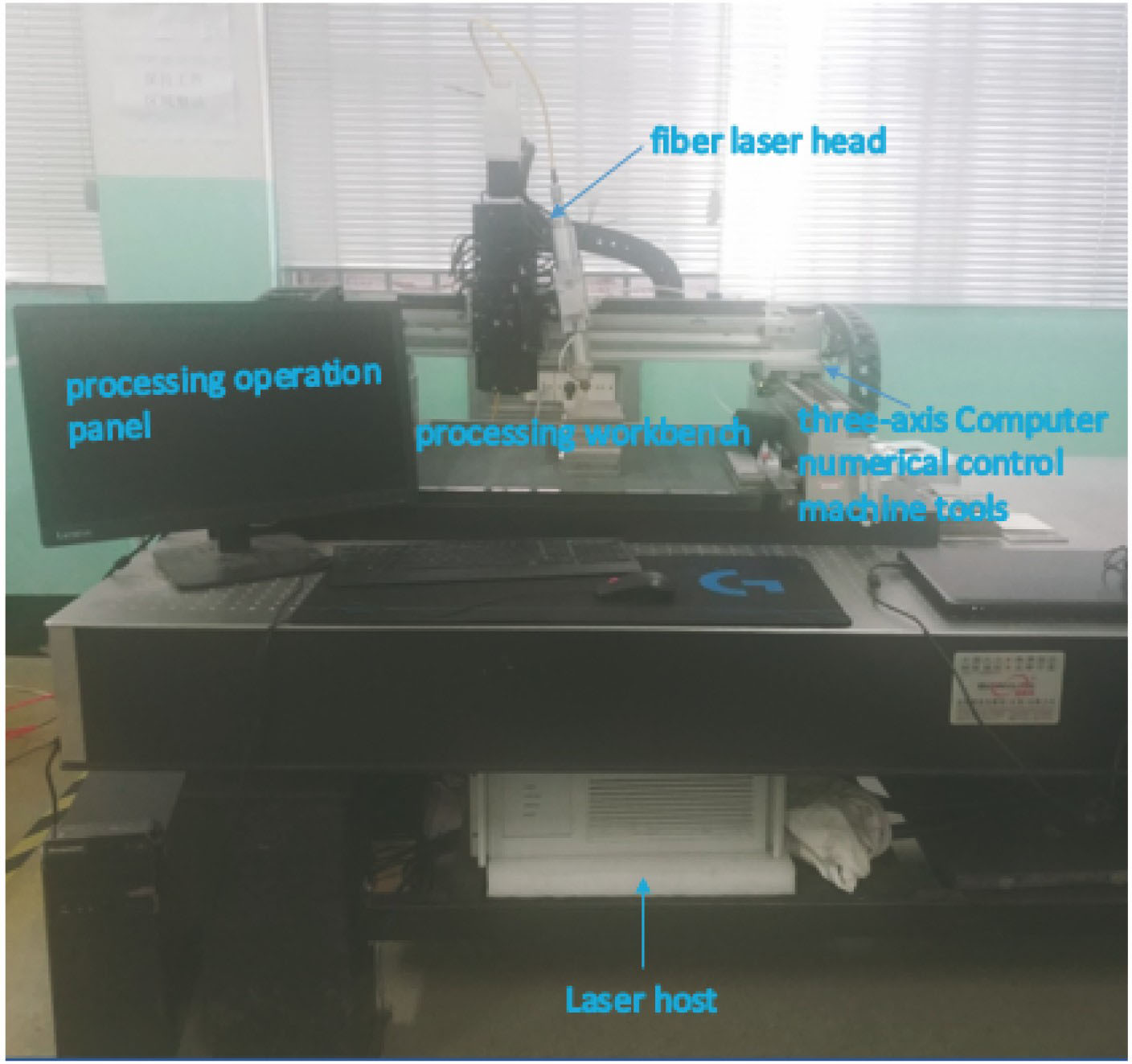

小模数齿轮齿面双道激光熔覆工艺  下载: 826次

下载: 826次

刘干成, 黄博. 小模数齿轮齿面双道激光熔覆工艺[J]. 中国激光, 2019, 46(10): 1002009.

Gancheng Liu, Bo Huang. Double-Pass Laser Cladding Process for Small-Modulus Gear-Tooth Surface[J]. Chinese Journal of Lasers, 2019, 46(10): 1002009.

[1] 马贤智.[\s]{1}实用机械加工手册[M].[\s]{1}沈阳:[\s]{1}辽宁科学技术出版社,[\s]{1}2002.[\s]{1}

Ma[\s]{1}XZ.[\s]{1}Practical[\s]{1}mechanical[\s]{1}working[\s]{1}manual[M].[\s]{1}Shenyang:[\s]{1}Liaoning[\s]{1}Science[\s]{1}and[\s]{1}Technology[\s]{1}Publishing[\s]{1}House,[\s]{1}2002.[\s]{1}

[2] 何力佳, 赵晓杰, 王函, 等. 45号钢基体光纤激光熔覆镍基合金的组织与性能[J]. 特种铸造及有色合金, 2015, 35(9): 909-912.

[3] 鲍志军.[\s]{1}小模数齿轮激光熔覆修复工艺试验研究[D].[\s]{1}上海:[\s]{1}上海海事大学,[\s]{1}2007.[\s]{1}

Bao[\s]{1}ZJ.[\s]{1}Experimental[\s]{1}study[\s]{1}on[\s]{1}repair[\s]{1}process[\s]{1}of[\s]{1}small[\s]{1}module[\s]{1}gear[\s]{1}laser[\s]{1}cladding[D].[\s]{1}Shanghai:[\s]{1}Shanghai[\s]{1}Maritime[\s]{1}University,[\s]{1}2007.[\s]{1}

[4] 刘洪喜, 曾维华, 张晓伟, 等. 不锈钢表面多道激光熔覆Ni基涂层的组织与性能[J]. 光学精密工程, 2011, 19(7): 1515-1523.

[7] 路阳, 巩禄, 杨效田, 等. 表层绝热对定向凝固Ni60合金涂层凝固行为的影响[J]. 中国表面工程, 2018, 31(4): 130-139.

[9] 刘亚楠, 孙荣禄, 牛伟, 等. Ti811表面激光熔覆复合涂层的微观组织及摩擦磨损性能[J]. 中国激光, 2019, 46(1): 0102010.

[10] 赵淑珍, 金剑波, 谢敏, 等. 扫描速率对激光熔覆Cu80Fe20偏晶涂层组织与耐磨性能的影响[J]. 中国激光, 2019, 46(3): 0302005.

刘干成, 黄博. 小模数齿轮齿面双道激光熔覆工艺[J]. 中国激光, 2019, 46(10): 1002009. Gancheng Liu, Bo Huang. Double-Pass Laser Cladding Process for Small-Modulus Gear-Tooth Surface[J]. Chinese Journal of Lasers, 2019, 46(10): 1002009.